Compressor with variable compressor inlet

A technology for compressors and compressor casings, which is applied in machine/engine, mechanical equipment, engine manufacturing, etc., can solve problems such as no longer, low efficiency, etc., and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

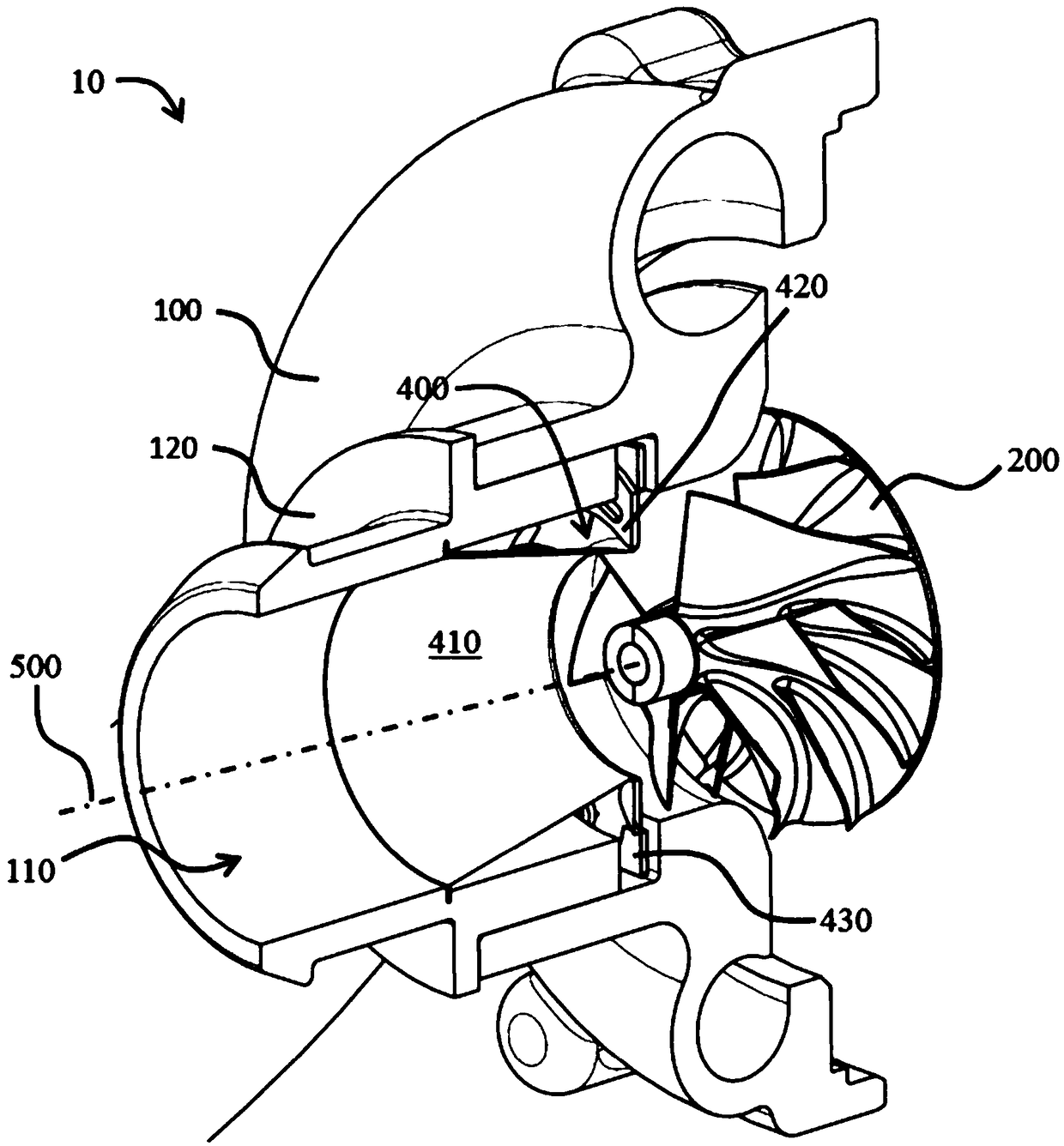

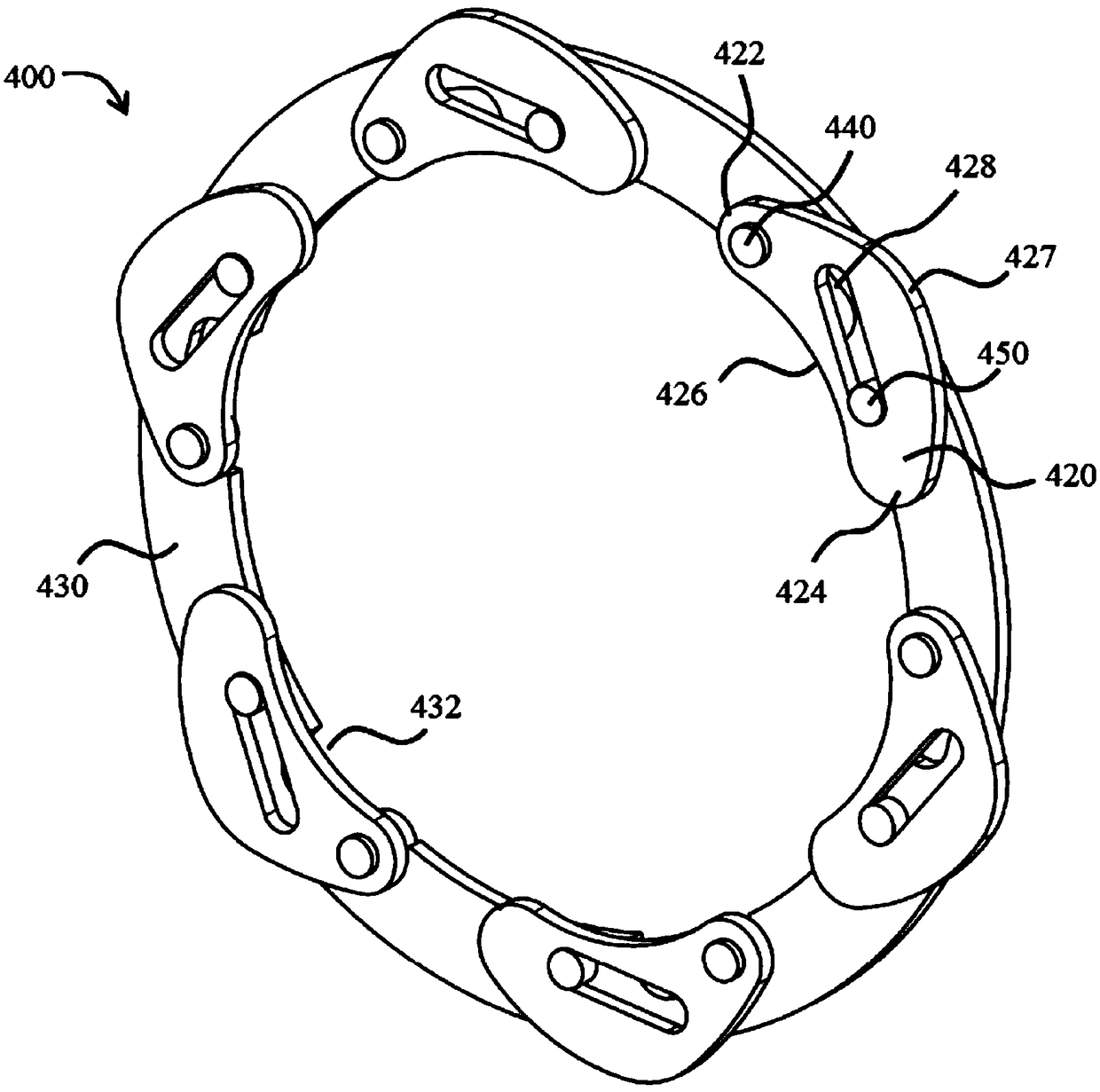

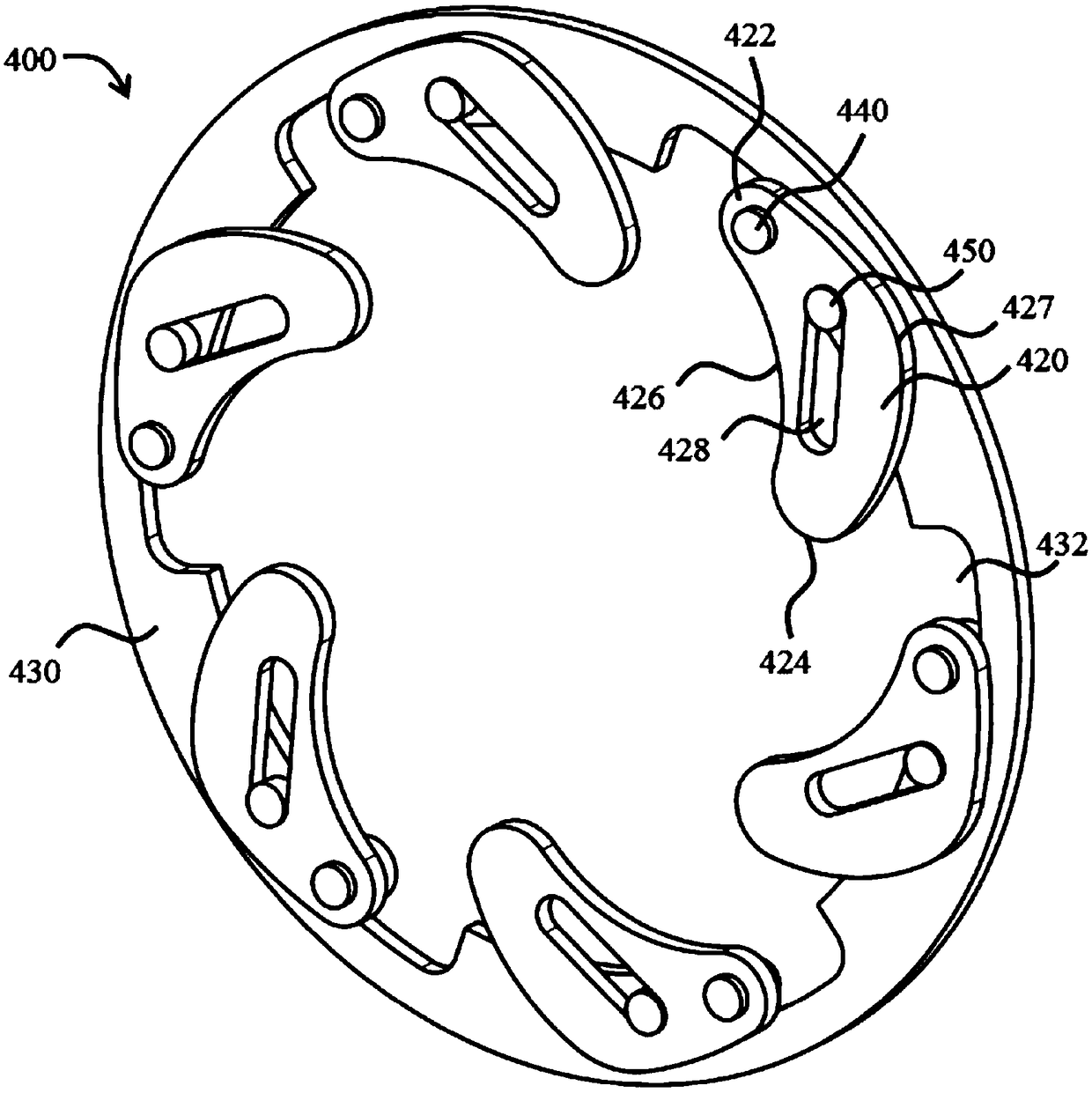

[0028] In the following, an embodiment of the compressor 10 according to the invention and also the regulating mechanism 400 according to the invention will be described by means of the drawings. All details and advantages described subsequently apply both to the adjusting mechanism 400 and to the compressor 10 comprising such an adjusting mechanism 400 and also to the charging device comprising the corresponding compressor 10 . The charging device can be, for example, an exhaust-gas turbocharger with a turbine, an electrically supported exhaust-gas turbocharger with a turbine and an electric motor, or a compressor 10 driven exclusively by an electric motor. Within the scope of the present application, a radial surface / lateral plane refers to a surface arranged substantially perpendicular to the axis of rotation 500 of the compressor 10 .

[0029]figure 1 An isometric cutaway view of one embodiment of a compressor 10 according to the present invention is shown. In the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com