Acrylic polyvinyl acetal film for a light directing article

A polyvinyl acetal, light orientation technology, applied in optics, applications, optical components, etc., can solve problems such as reducing high temperature stability and difficult to print

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

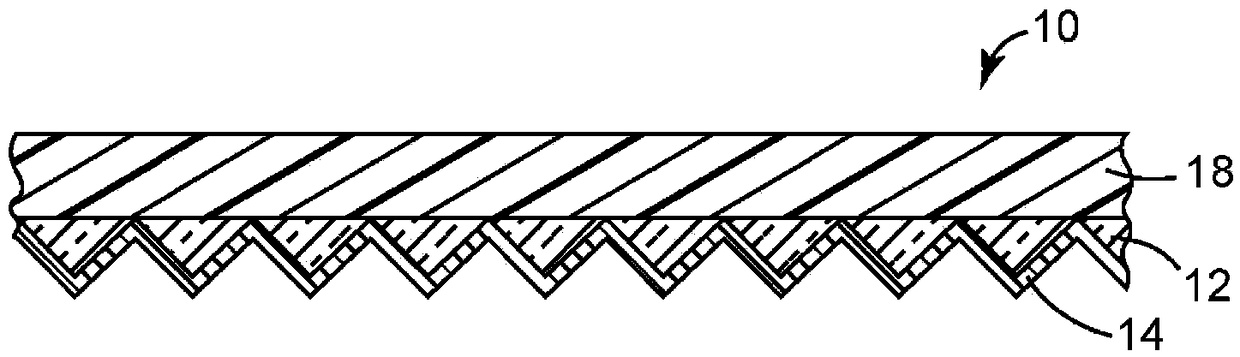

[0157] Primer 1 was coated onto a second sample of PET 1 at a thickness of 0.002 inches (51 microns) using a notch bar coater. The Primer 1 composition was exposed to a total UV-A energy of 3600 mJ / cm2 using multiple fluorescent lamps having a peak emission wavelength of 350 nm to obtain a non-pressure sensitive adhesive (PSA) acrylic on PET 1 membrane. Adhesive slurry 1 was coated onto PET 1 at a thickness of 0.002 inches (51 microns) using a notch bar coater. The irradiated non-PSA acrylic film / PET 1 composition was brought into intimate contact with the adhesive slurry 1 coated PET 1 using a two-roll coating station with a total gap setting of 0.008 inches (203 microns) and using a 350 Multiple fluorescent lamps with a peak emission wavelength in the nanometer were exposed to a total UV-A energy of 4263 mJ / cm2. A construction with PET 1 , PSA, non-PSA acrylic film and PET 1 in sequence was obtained. Next, the PET 1 liner was removed from Lot 9 from the DLX2 test to expos...

Embodiment 2

[0159] The components of Base 2 were added to a MAX 100 white speed mixer (available from FleckTek, Inc., Landrum, SC) and mixed at 3500 RPM for 5 minutes. Primer 2 was coated between untreated PET liners at a thickness of 2.0 mils and exposed to UVA light. Total Energy Use Powermap equipped with low-intensity sensing head TM Radiometer (purchased from EIT Company (EIT Inc., Sterling, VA) of Sterling, Virginia) to measure and is 1824mJ / cm 2 .

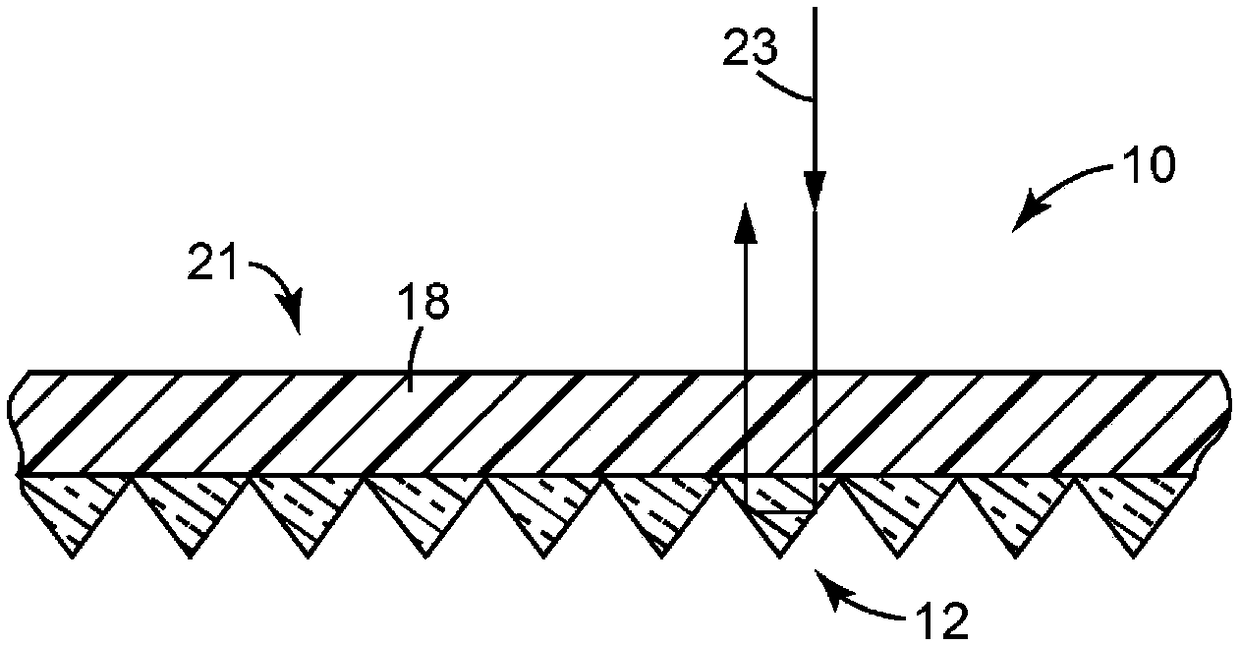

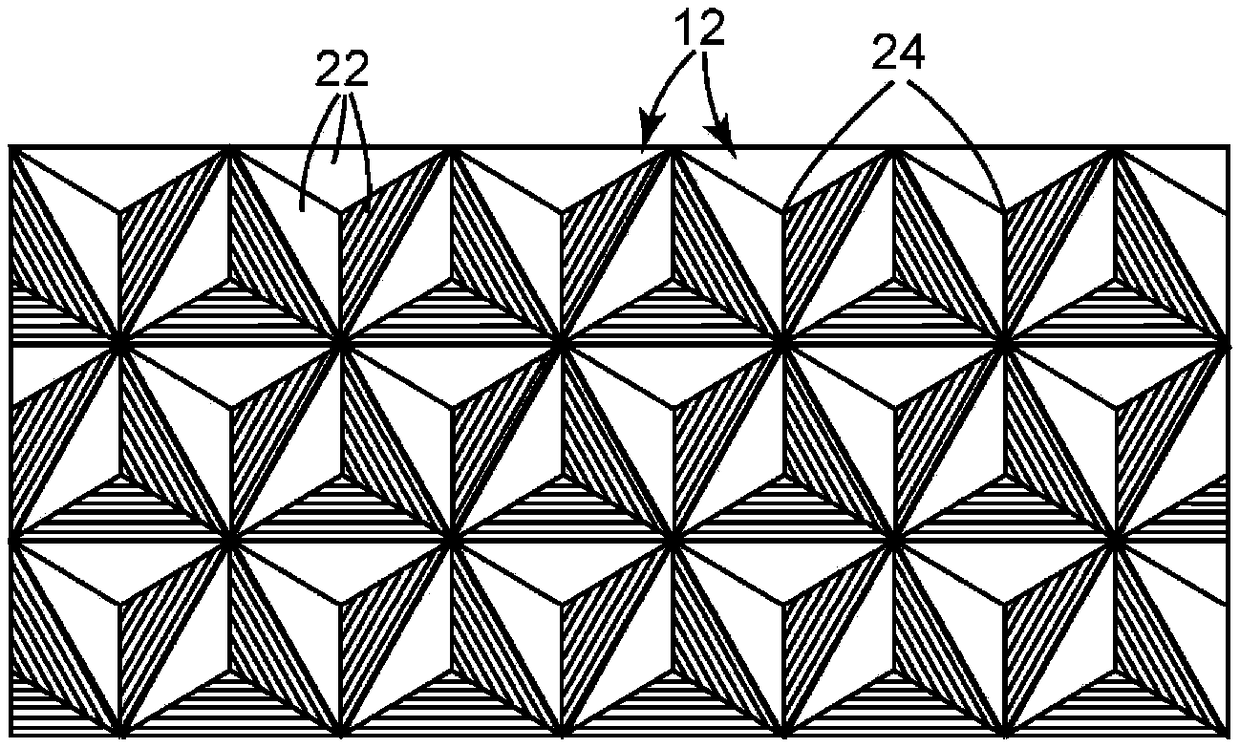

[0160] A plurality of optically active elements, specifically microreplicated cube corner structures, are provided on the layer as generally described in U.S. 5,691,846, the disclosure of which is incorporated herein by reference in its entirety. The cube corner structure (before dividing the structure into individual cubes) has 3 sets of intersecting grooves with a pitch of 0.004 inches (i.e., the main groove spacing) and a 58 / 58 / 64 degree base triangular hole, allowing the cube corner The height of the corner elements is 50.0 micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com