An automatic loading and unloading mechanism for a cold axial vibration forming hydraulic press

A technology of automatic loading and unloading, axial vibration, applied in the direction of feeding device, manufacturing tool, positioning device, etc., can solve the problems of unstable product quality, injured operator, workpiece flying out, etc., to reduce labor costs, location Accurate and reliable results with reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

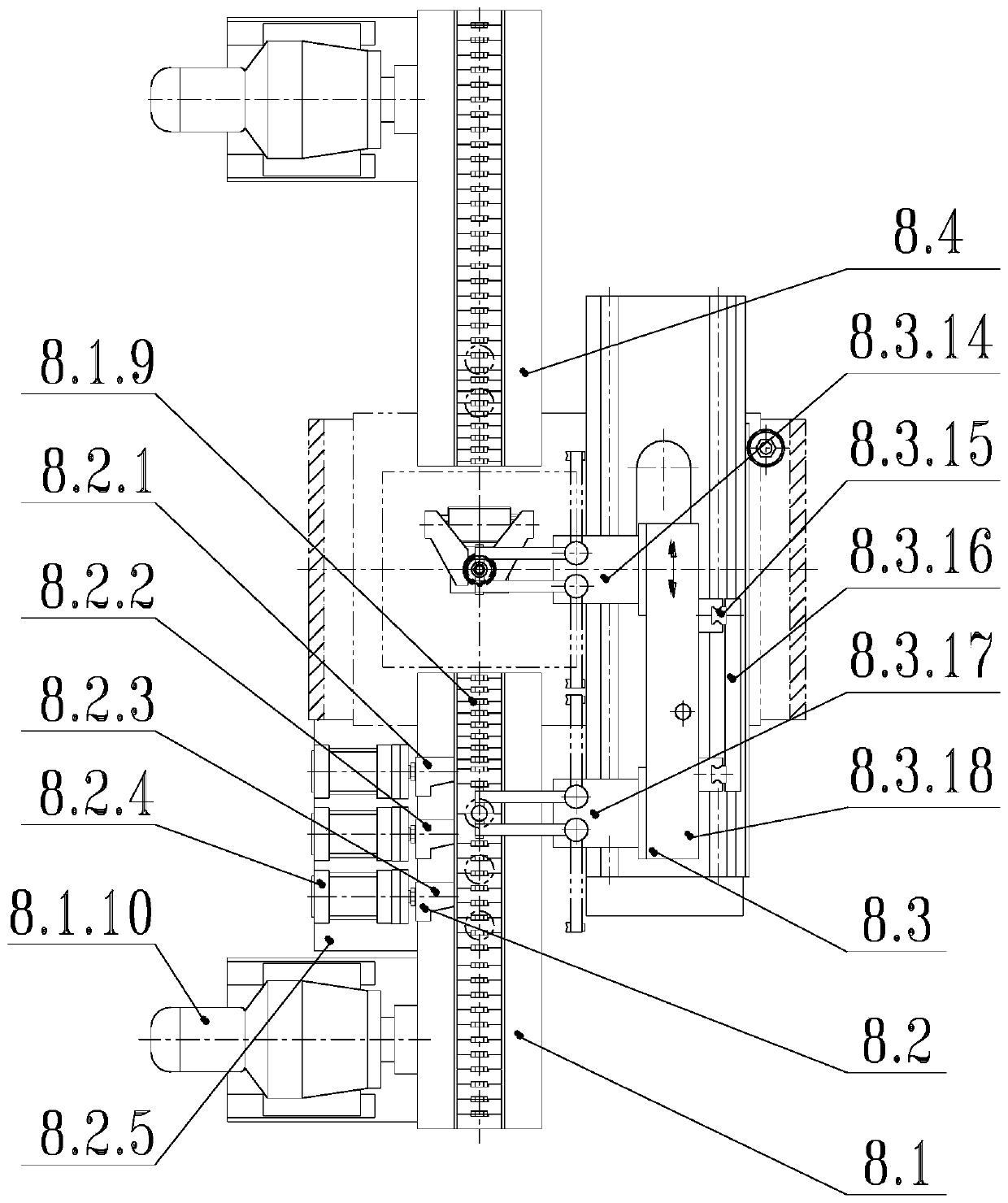

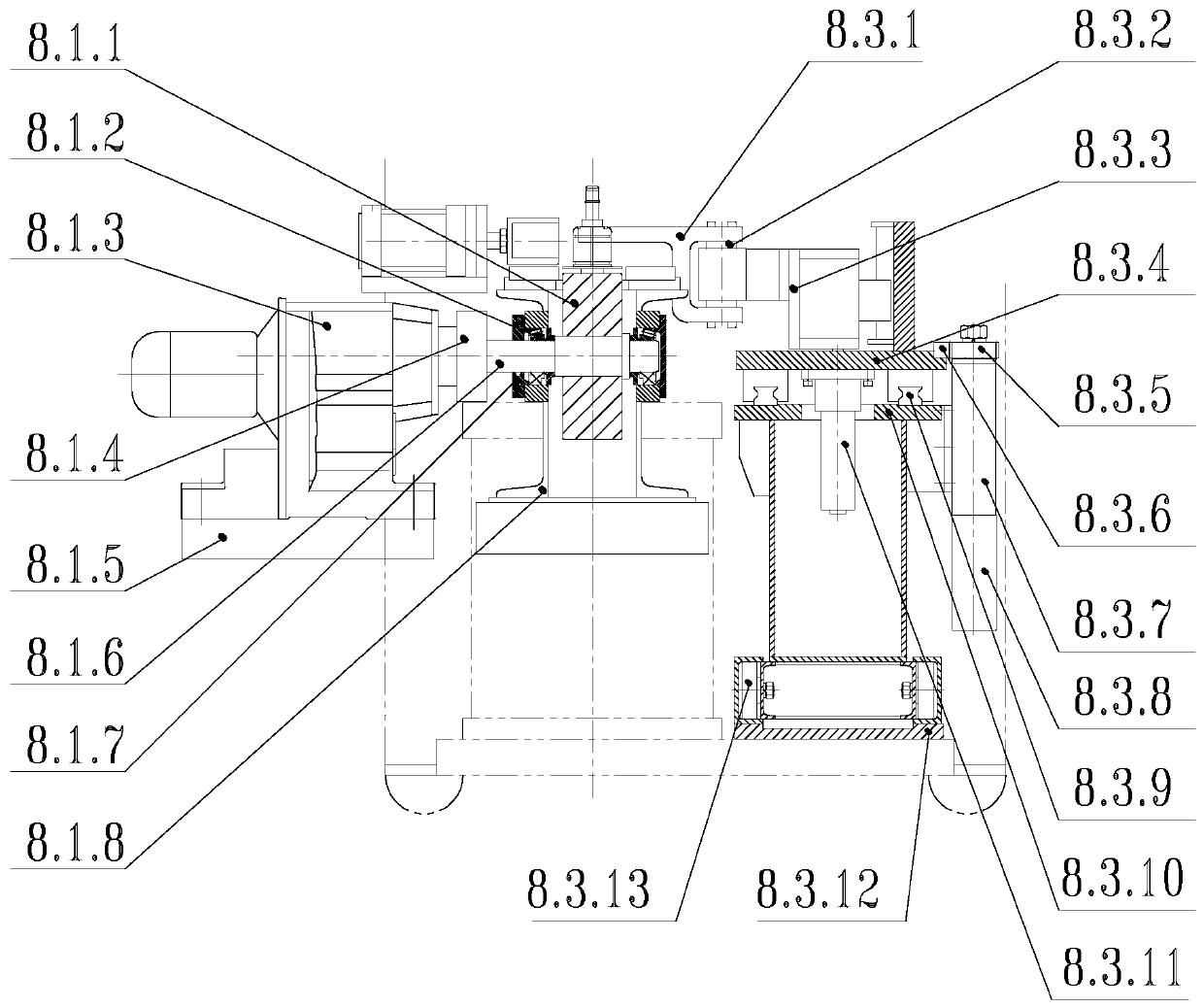

[0018] This embodiment provides an automatic loading and unloading mechanism for a cold axial vibration forming hydraulic press, which is used for automatic loading and unloading of workpieces.

[0019] see figure 1 with figure 2 , the automatic loading and unloading mechanism includes a feeding system 8.1, a positioning system 8.2, an operating system 8.3, and a feeding system 8.4; wherein, the feeding system is used to transport the workpiece to the front side of the main machine; the positioning system is used to place the workpiece Positioned on the feeding system; the operating system is used to transport the workpiece from the feeding system to the lower mold, and the workpiece from the lower mold to the unloading system; the unloading system is used to unload the workpiece.

[0020] The feeding system 8.1 includes two plate rollers 8.1.1, bearings 8.1.2, reducers 8.1.3, couplings 8.1.4, connecting frames 8.1.5, two roller shafts 8.1.6, bearing caps 8.1 .7. Support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com