Adjustable damping type Cs axis continuous machining stabilizing device

A technology of stabilizing device and adjusting damping, applied in the field of CNC lathes, can solve the problems of poor surface processing quality of workpieces, easy vibration of CNC lathes, etc., and achieves the effects of simple structure, low price, and vibration elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

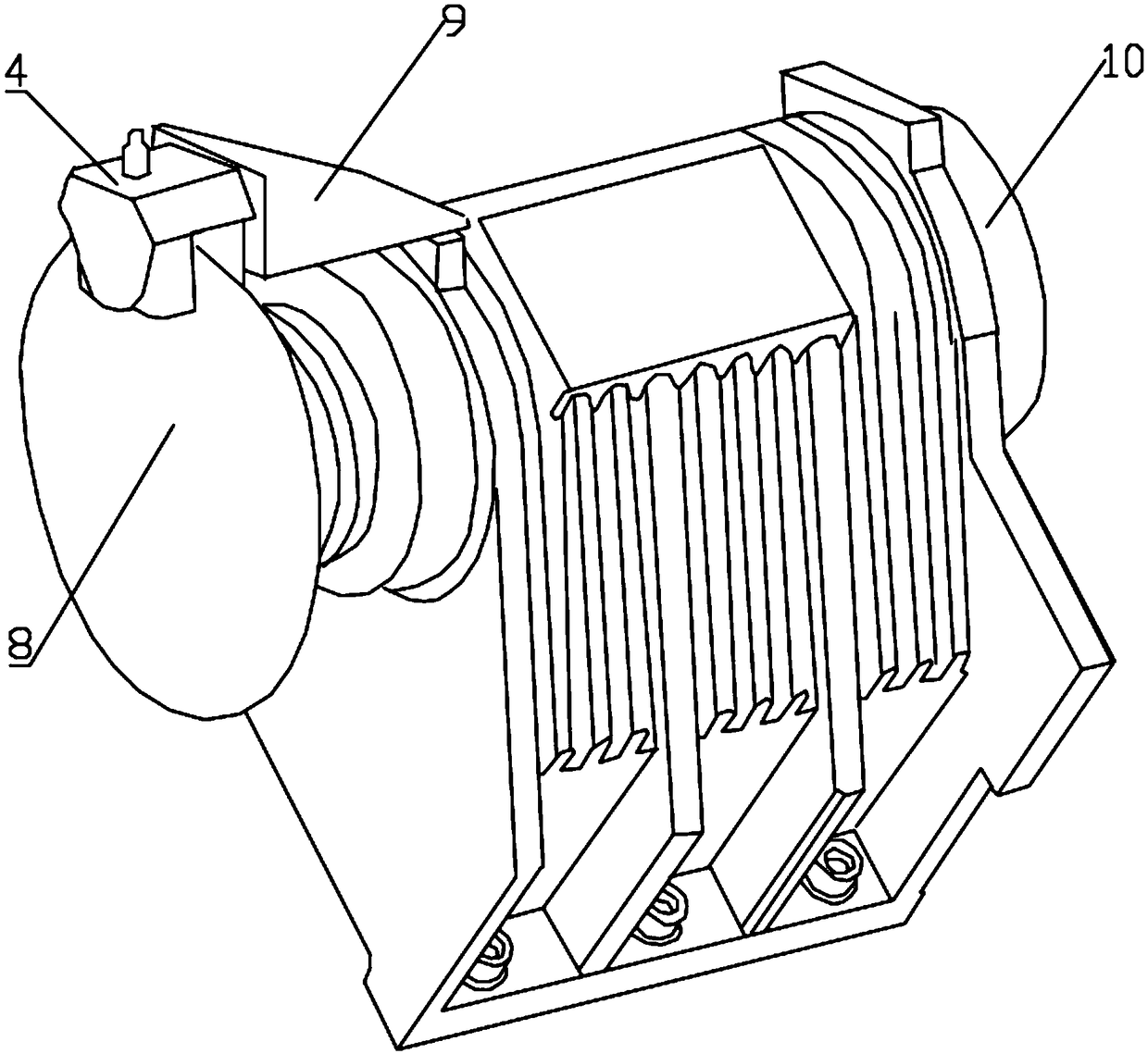

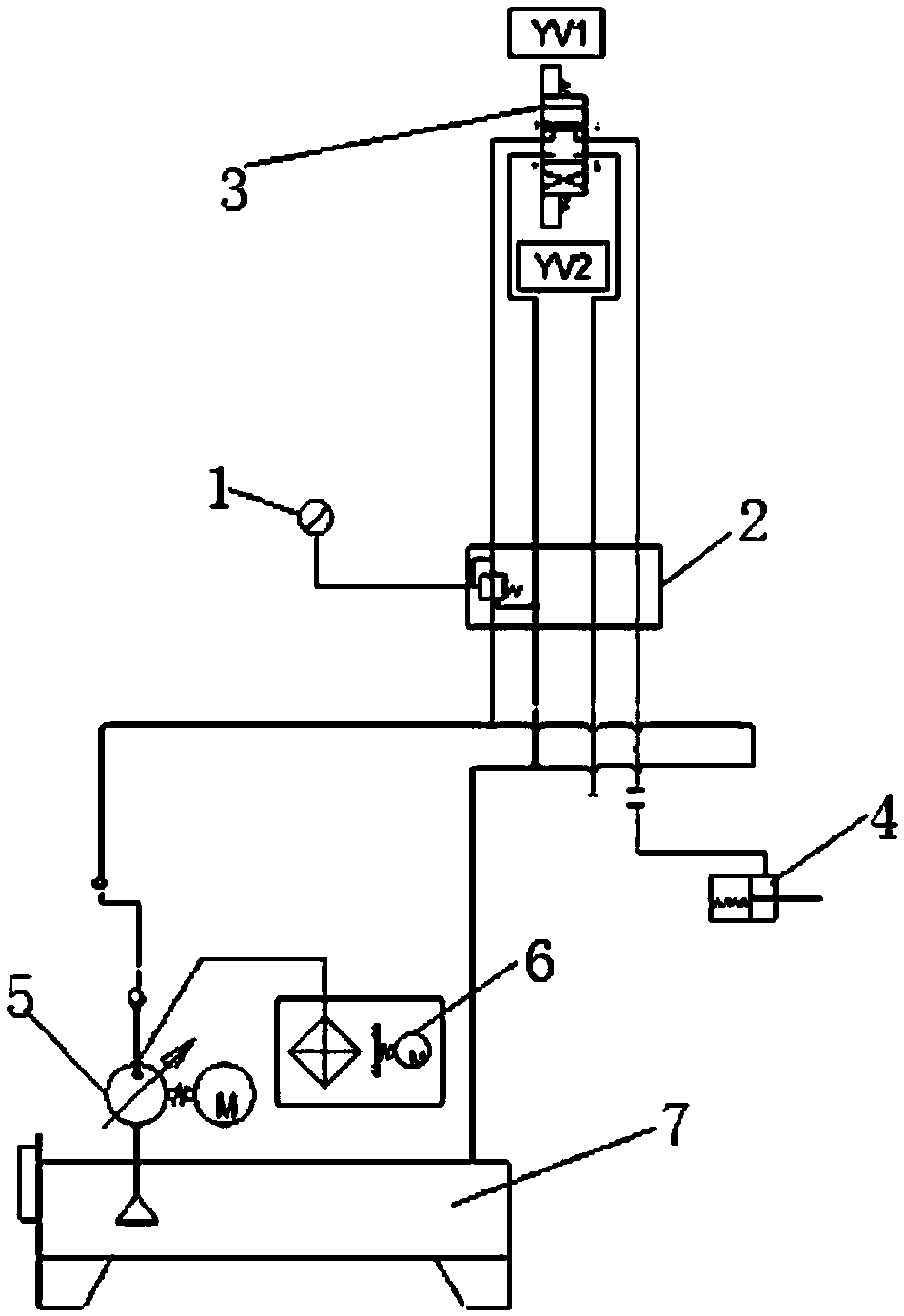

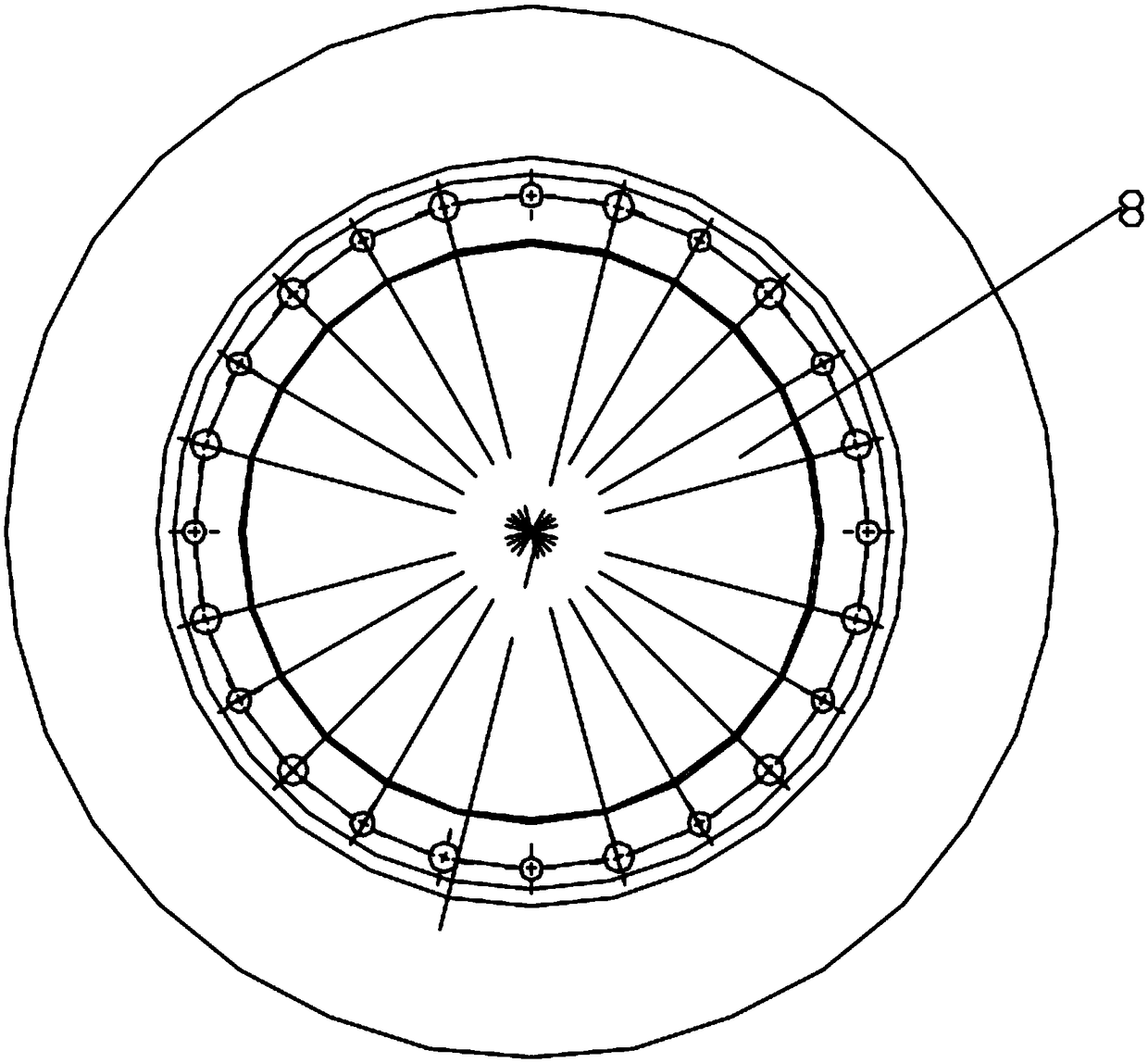

[0021] An adjustable damping type Cs-axis continuous processing stabilization device, including a mounting bracket 9, a hydraulic tank 7 and a hydraulic motor 5 are installed inside the mounting bracket 9, the hydraulic tank 7 is connected to the hydraulic motor 5, and the middle of the mounting bracket 9 A main shaft 10 is installed at the position and the main shaft 10 runs through the mounting bracket 9. A brake disc 8 is installed on the end of the main shaft 10 and a brake damping device 4 is connected to the brake disc 8. The brake damping device 4 is connected to the hydraulic tank 7, and the hydraulic motor 5 is connected to the brake disc 8. Pressure valve 2 is connected and pressure relief valve 2 is connected with reversing valve 3. The hydraulic motor 5 is connected with the cooling device 6 to facilitate the cooling of the hydraulic motor 5 and ensure the normal operation of the hydraulic motor 5 . Cooling device 6 adopts water cooling device, the technology is ma...

Embodiment 2

[0023] An adjustable damping type Cs-axis continuous processing stabilization device, including a mounting bracket 9, a hydraulic tank 7 and a hydraulic motor 5 are installed inside the mounting bracket 9, the hydraulic tank 7 is connected to the hydraulic motor 5, and the middle of the mounting bracket 9 A main shaft 10 is installed at the position and the main shaft 10 runs through the mounting bracket 9. A brake disc 8 is installed on the end of the main shaft 10 and a brake damping device 4 is connected to the brake disc 8. The brake damping device 4 is connected to the hydraulic tank 7, and the hydraulic motor 5 is connected to the brake disc 8. Pressure valve 2 is connected and pressure relief valve 2 is connected with reversing valve 3. The pressure reducing valve 2 is also connected with a pressure gauge 1, which can visually display the current pressure. The reversing valve 3 adopts a two-position four-way reversing valve, which is convenient for controlling the effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com