High-accuracy scraper device for electronic shaft printer

A technology of electronic shaft printing machine and scraper device, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of inconvenient installation and adjustment, inconvenient operation, low precision, etc., and achieve smooth movement of the scraper, easy lifting, and structural stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described

[0013] preferred embodiment

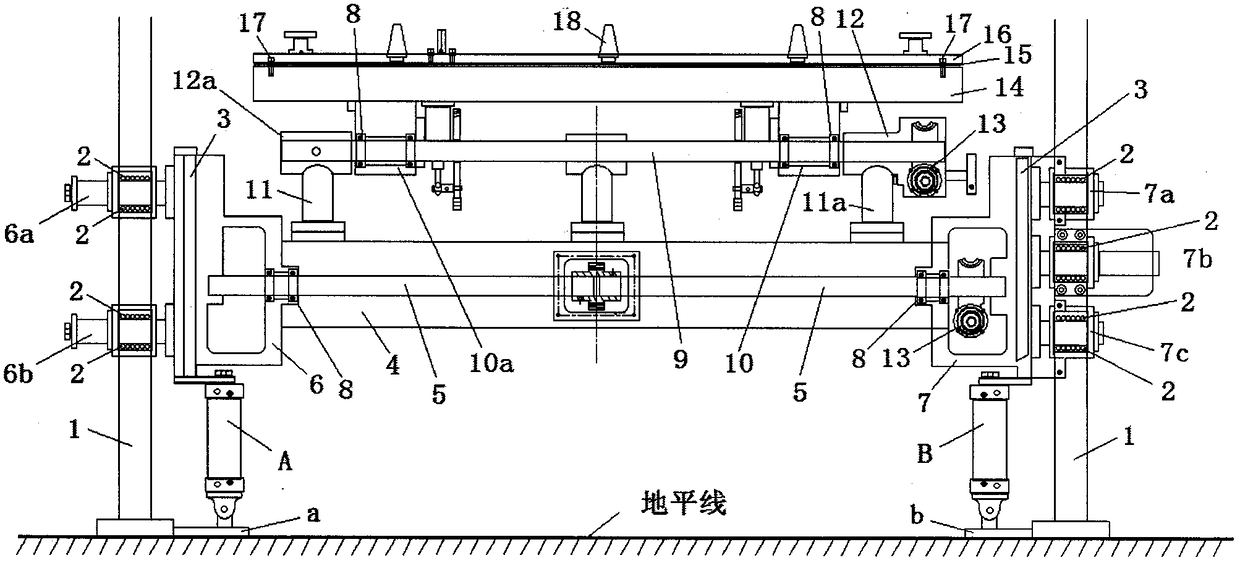

[0014] combine figure 1 , in the figure 1 is the column, 2 is the linear bearing, 3 is the linear guide rail, 4 is the overall bridge platform, 5 is the scraper lifting gear shaft, 6 is the left arm of the bridge platform, 6a is the upper slide of the left arm, 6b is the left Arm slide, 7 is the right arm of the bridge platform, 7a is the upper slide of the right arm, 7b is the middle slide of the right arm, 7c is the slide of the right arm, 8 is the deep groove bearing, 9 is the rotating shaft of the scraper, 10 and 10a are scrapers Slider seat, 11 is the left fixed seat of the scraper shaft, 11a is the right fixed seat of the scraper shaft, 12 is the rotating worm wheel seat of the scraper, 12a is the worm wheel seat, 13 is the rotating seat, 14 is the scraper bracket, 15 is the scraper, 16 is the scraper Beading, 17 are fixed scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com