Hub disassembling and assembling device

A disassembler and wheel hub technology, which is applied in wheel assembly equipment, wheels, wheel manufacturing, etc., can solve the problems of rim damage and low efficiency, and achieve the effects of high disassembly efficiency, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

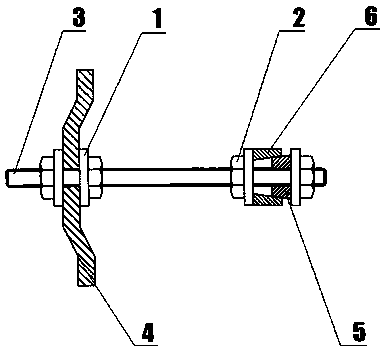

[0008] Combine below figure 1 The present invention is further described.

[0009] A wheel hub disassembler, comprising gasket 1, nut 2, screw mandrel 3, one end of said screw mandrel 3 is provided with rotating rod 4, rotating rod 4 is fixed with screw mandrel 3 by nut 2 and gasket 1, said A tapered block 5 is installed on the outer wall of the other end of the screw mandrel 3, and the radially outer side of the tapered block 5 is sleeved with an expansion block 6 matched with the taper of the tapered block 5.

[0010] When in use, insert the side of the screw rod 3 with the tapered block 5 into the hub sleeve of the rear hub of the passenger car, and then turn the rotating rod 4, because the rotating rod 4 is fixed on the screw rod 3 through the gasket 1 and the nut 2 , at this moment the screw mandrel 3 will rotate along with it, and under the effect of the rotating torque, the conical block 5 expands to the outside of the screw mandrel 3, because the expansion block 6 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com