Traction motor bearing temperature monitoring alarm control method and system and related device

A technology for traction motors and control methods, which is applied to control devices, temperature measurement in motors, electrical devices, etc., and can solve problems such as speed reduction, inability to effectively ensure safe operation of EMUs, and potential safety hazards of trains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

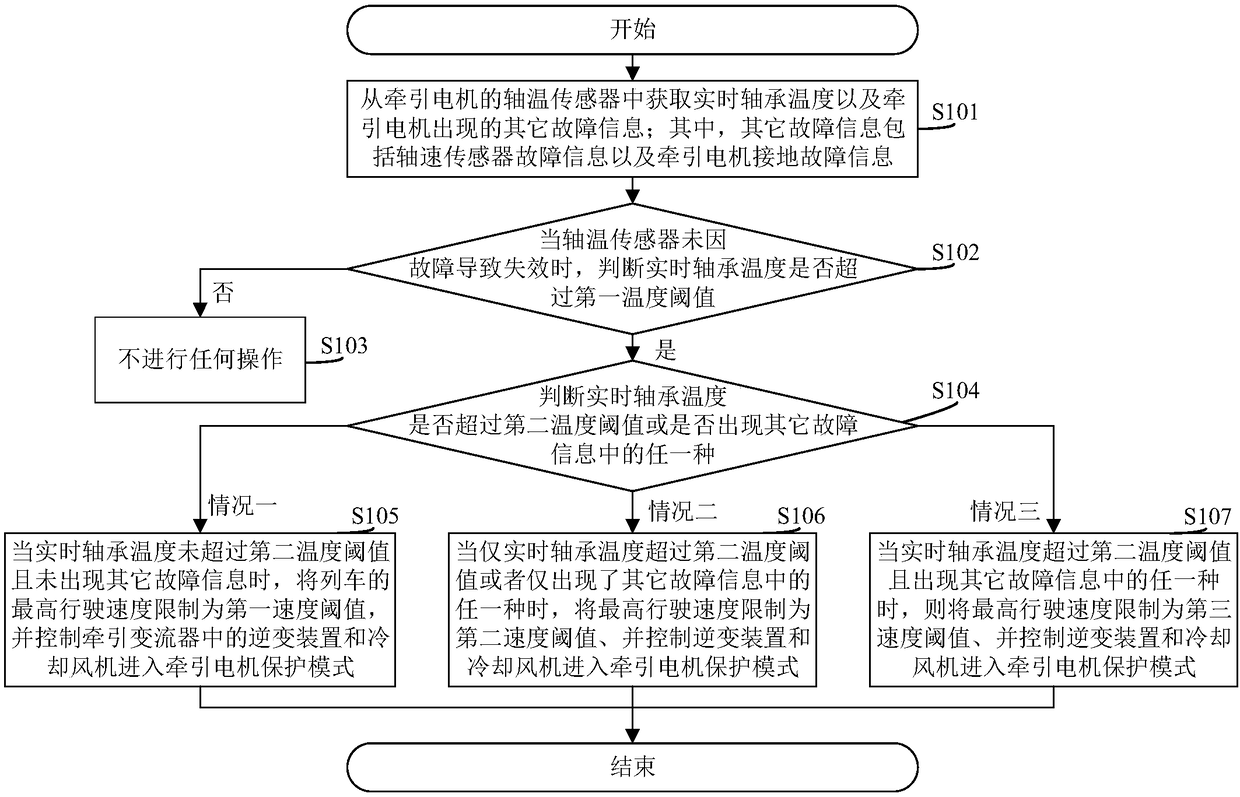

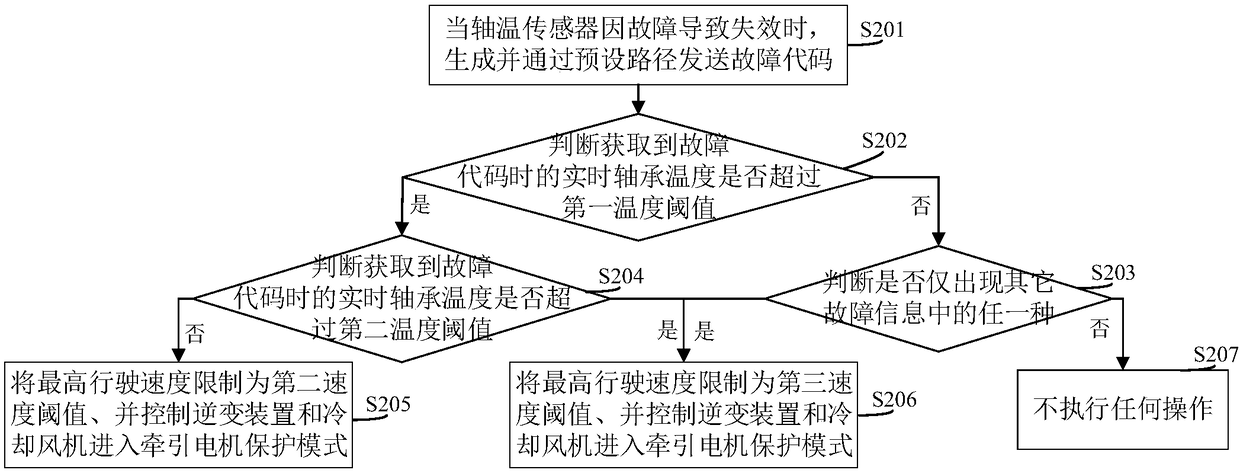

[0124] Reasonable combinations of the occurrence and sequence of the aforementioned four events can be summarized into 9 cases and three-level alarms. The specific implementation is as follows:

[0125] Level 0: zero-level alarm

[0126] Case M1: The axle temperature sensor is faulty.

[0127] Vehicle Response: Diagnostic codes only.

[0128] Level 1: Level 1 alarm

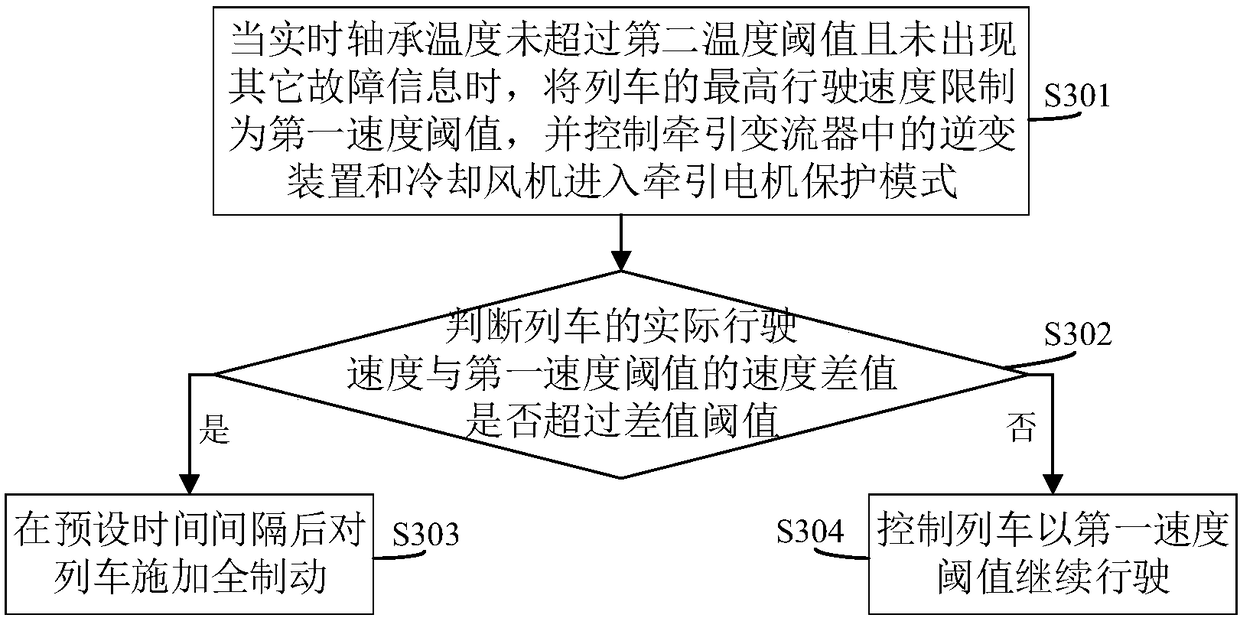

[0129] Situation M2: When the vehicle has no traction bearing monitoring-related fault diagnosis, the event is directly monitored: T>120°C.

[0130]Vehicle response: The speed limit is 200km / h. If the speed is too high, full braking will be automatically applied after 300s; the inverter device has no torque output; the motor cooling fan is forced to cool at high speed.

[0131] Level 2: Secondary alarm

[0132] There are three situations in which the secondary alarm of the vehicle can be generated, which are:

[0133] Situation M3: After the bearing temperature T>120°C is detected first, the bearing temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com