Train brake release system and train

A brake mitigation and train technology, which is applied in the direction of brakes, brake components, brake transmission devices, etc., can solve the problems of increasing accidents, time-consuming and labor-consuming, and failure to start, so as to enhance safety and stability, reduce The probability of accidents and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

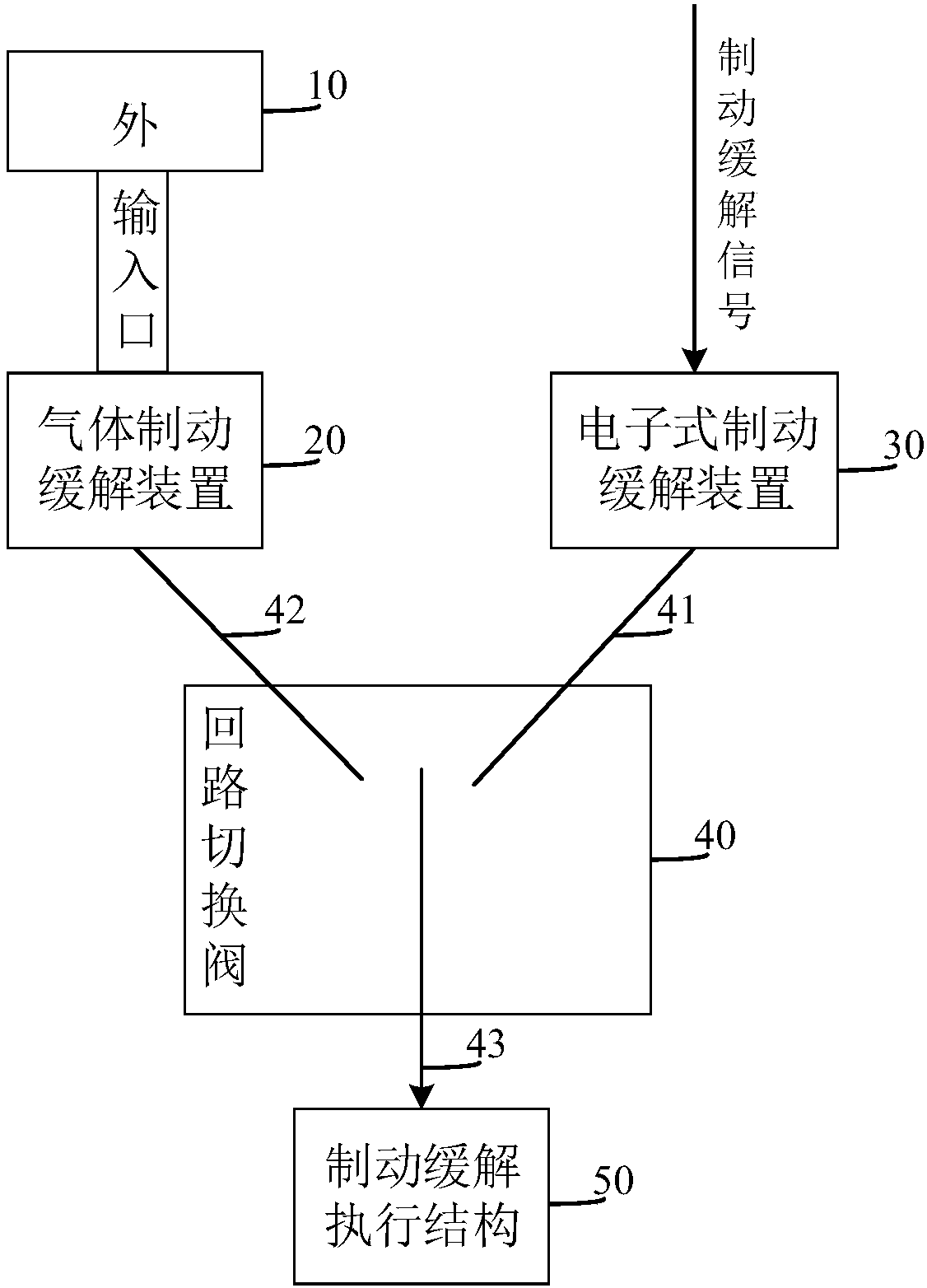

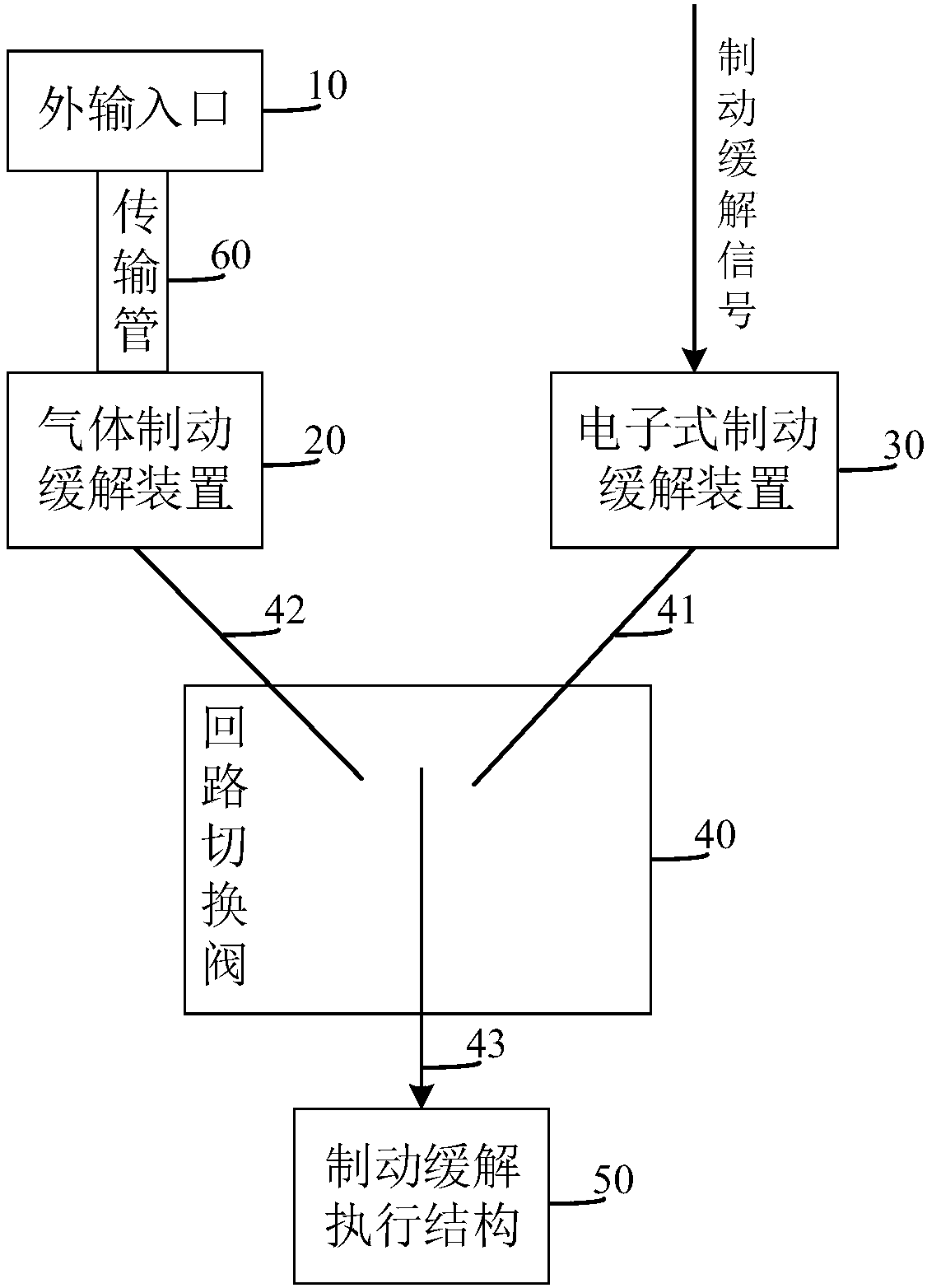

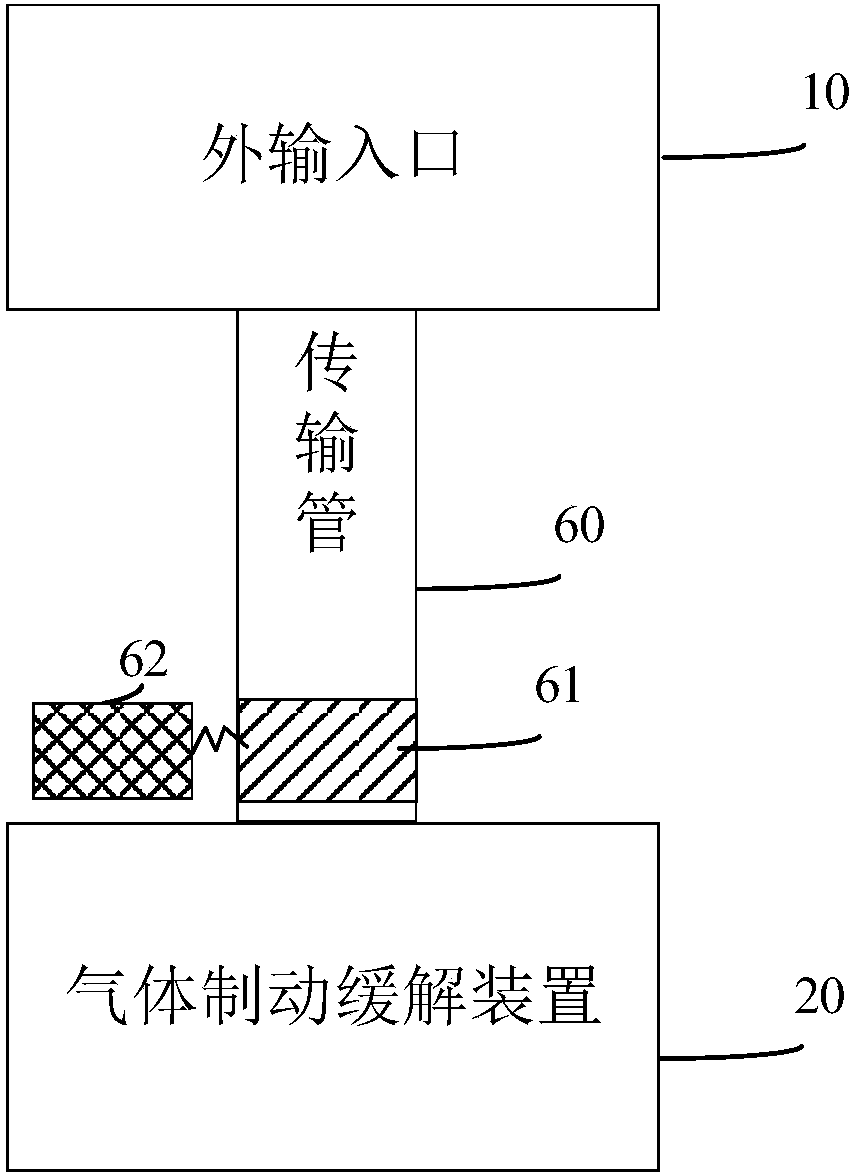

[0039] The core of the present invention is to provide a train brake mitigation system and train. On the basis of the original electronic brake mitigation device, a gas brake mitigation device is added, and an external compressed gas input port and transmission are correspondingly provided. The tube makes it possible to use the compressed gas with a preset pressure provided by the traction locomotive to activate the air brake relief device, so that the braked train can be quickly released from the braked state. Significantly improves the efficiency of braking mitigation without consuming precious manpower, greatly reducing the probability of accidents, and enhancing the safety and stability of the train.

[0040] In order to make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com