A method of bottling glass bottles

A glass and bottle filling technology, applied in liquid bottling, packaging, bottle filling and other directions, can solve the problem of slow foam dissipation

Active Publication Date: 2020-06-16

重庆兆峰玻璃晶品有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The object of the present invention is to provide a method for bottling glass bottles, so as to solve the problem in the prior art that the liquids that are prone to foam and gas, such as beer, are bottled when the foam is generated and the foam dissipates slowly.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

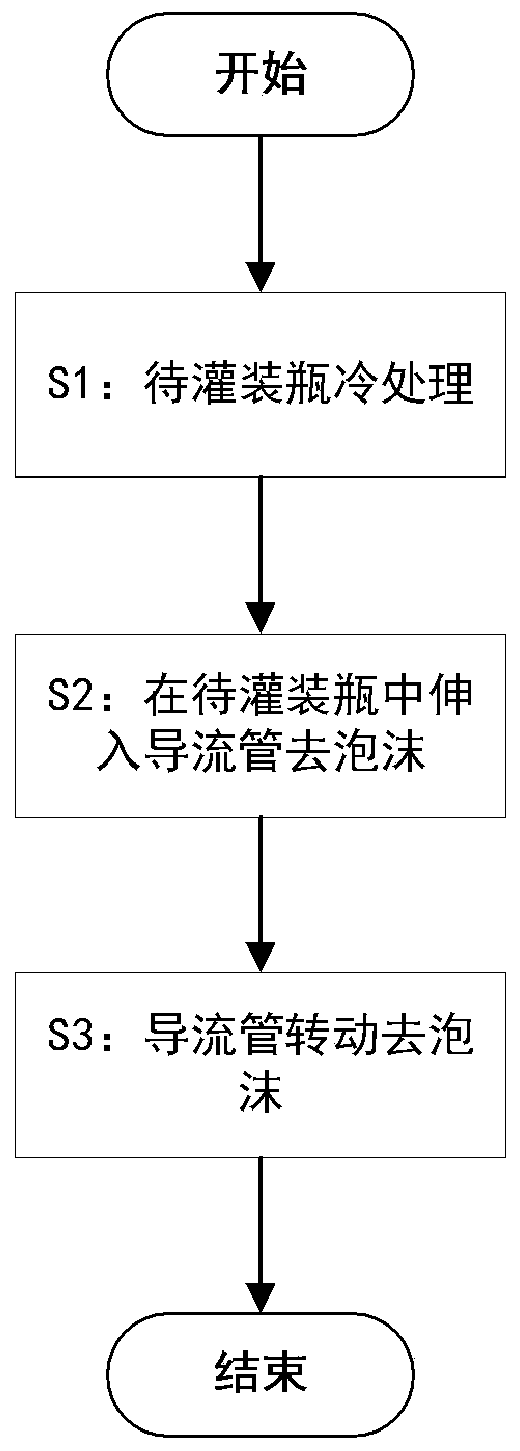

[0031] Such as figure 1 Shown, a kind of method for glass bottle bottling, comprises the steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

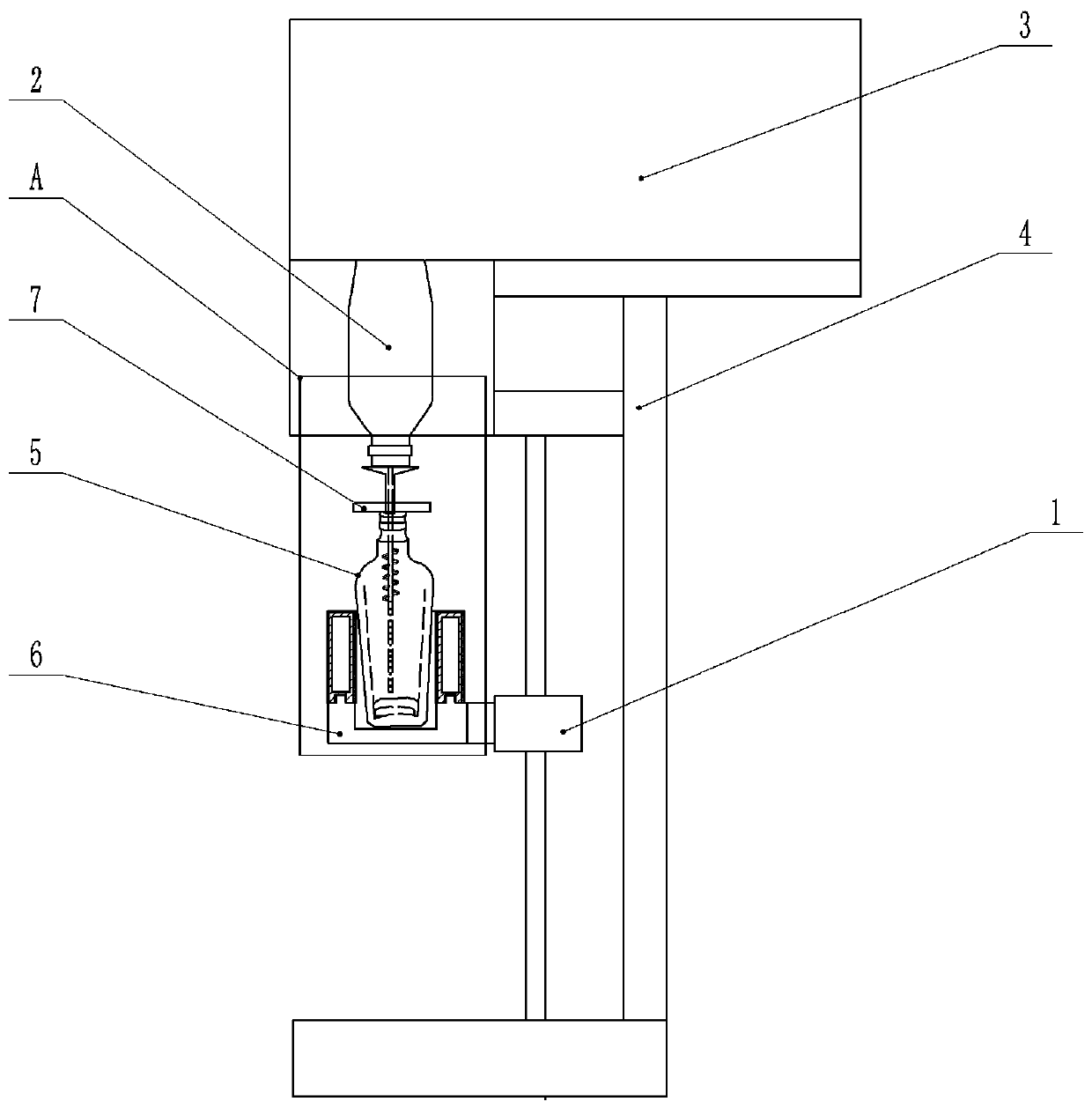

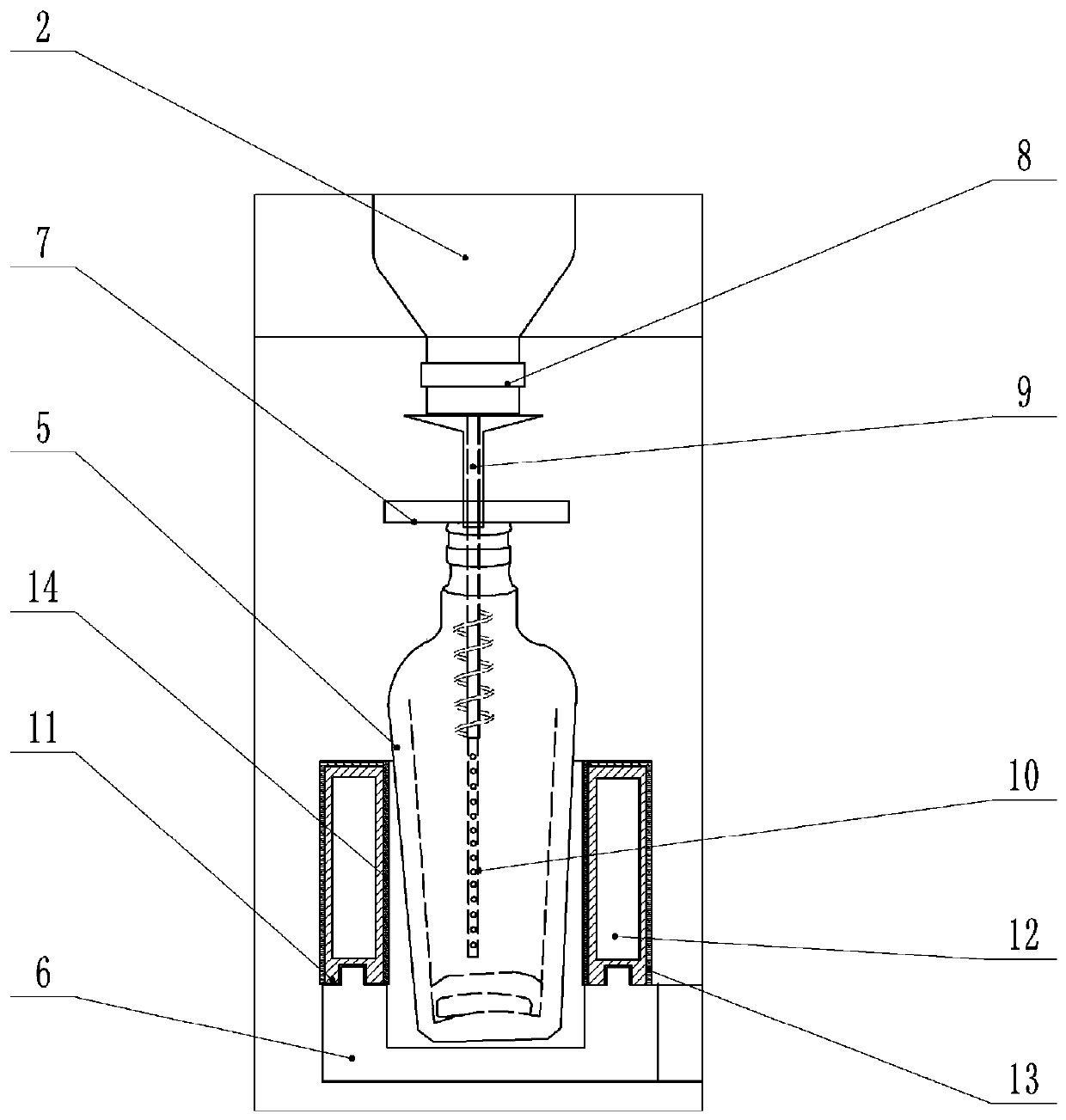

The invention relates to the field of bottle filling, in particular to a glass bottle filling method. The glass bottle filling method comprises the following steps that S1, the temperature of a storage barrel using for storing liquid which is likely to generate froth is detected, and then cold treatment is conducted on a to-be-filled bottle according to a detected temperature value, so that the temperature of the to-be-filled bottle is made lower than the temperature of the storage barrel; S2, the to-be-filled bottle is filled with the liquid which is likely to generate froth, a guide pipe with a rough surface is stretched into the to-be-filled bottle during filling, and bubbles generated after the liquid which is likely to generate froth enters the to-be-filled bottle are punctured when making contact with the guide pipe; and S3, non-punctured bubbles move upwards to generate upward pushing force, and when the pushing force is greater than the rotating force of the guide pipe, fan blades arranged on the outer surface of the guide pipe are pushed by the pushing force to drive the guide pipe to rotate, and then the bubbles are punctured when making contact with the rotating guide pipe. The glass bottle filling method is suitable for filling bottles with liquid which is likely to generate froth.

Description

technical field [0001] The invention relates to the field of bottle filling, in particular to a method for glass bottle filling. Background technique [0002] When shopping, most of the purchased items need to be packaged, and liquid purchases are usually bottled, such as: cooking wine, vinegar, and soy sauce as seasonings, as well as cola, soda water, and mineral water as beverages , Another example is beer and liquor. However, the matters needing attention for bottling of different liquids are not consistent. [0003] Taking beer as an example, since beer generally contains about 0.5% carbon dioxide gas. This carbon dioxide gas is produced during the fermentation process and incorporated into the beer, but the amount of this carbon dioxide gas incorporated into the beer is about twice that of the normal pressure, that is to say, it is supersaturated. Therefore, when the pressure value between the beers changes, the carbon dioxide gas will be collided to form a gas, whic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B67C3/22B67C3/24B67C3/26

CPCB67C3/22B67C3/24B67C3/26B67C2003/2671

Inventor 邓军华

Owner 重庆兆峰玻璃晶品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com