A surface oil slick cleaning ship

A technology for cleaning oil slicks on the water surface and cleaning ships, which is applied to the cleaning of open water surfaces, general water supply saving, water conservancy projects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

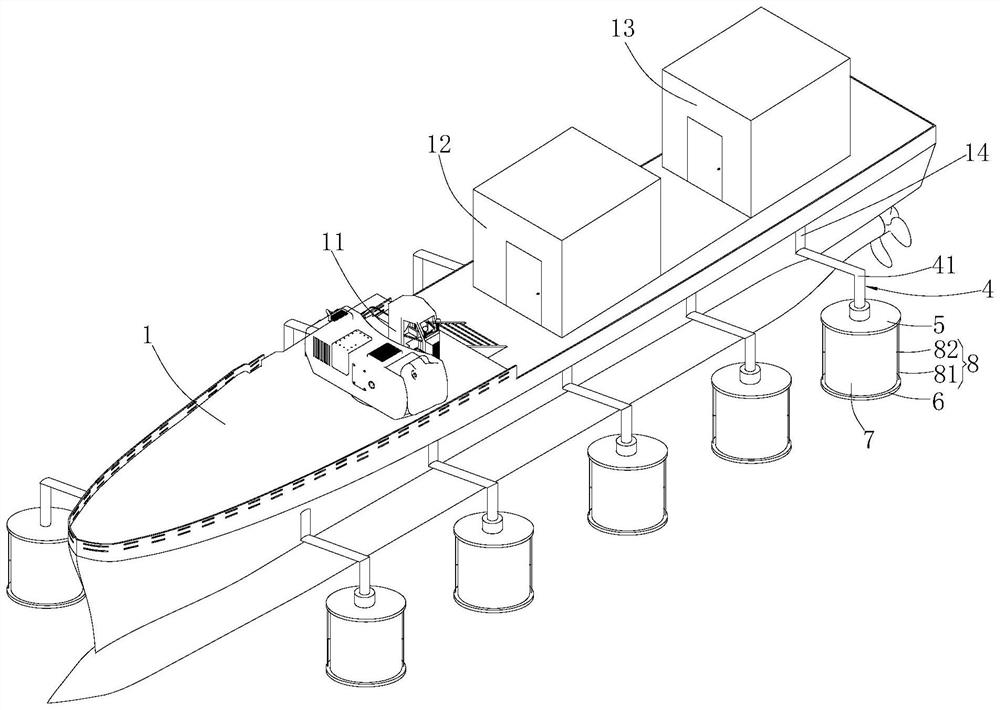

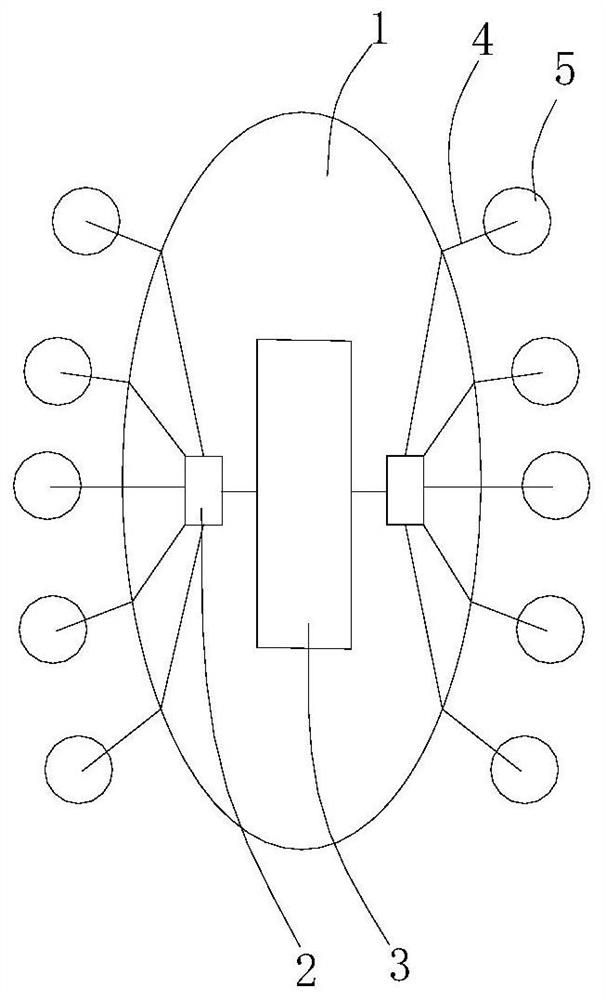

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

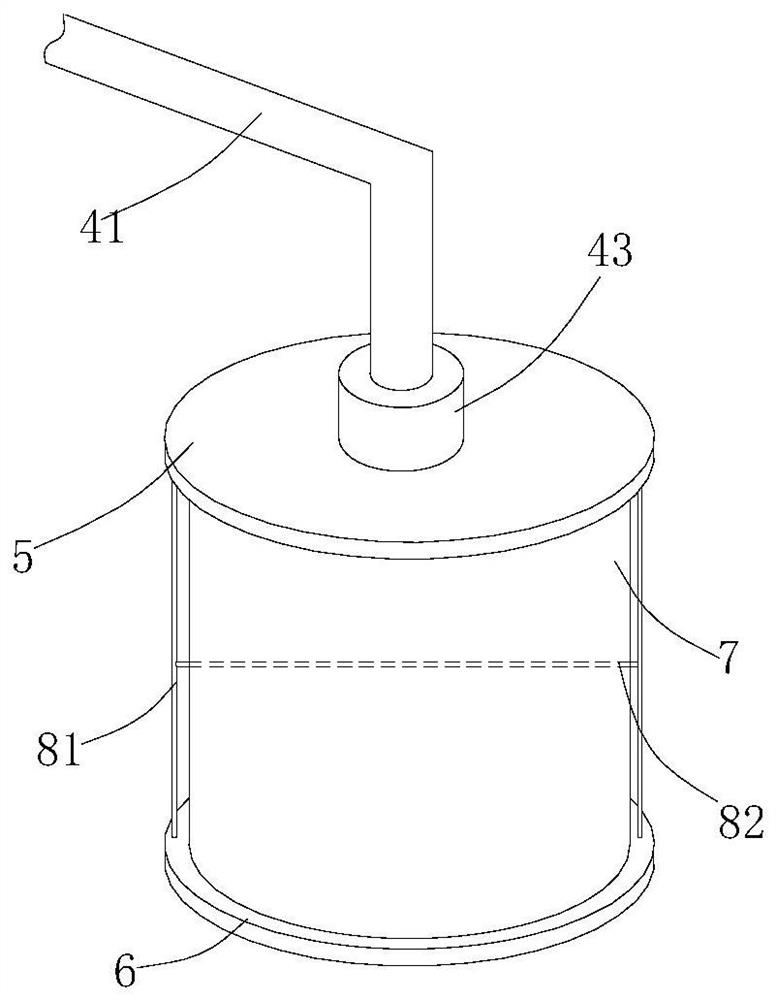

[0023] combine Figure 1 to Figure 6 , an oil slick cleaning ship on the water surface, comprising a hull 1, an oil pump 2, an oil tank 3 and an oil suction mechanism, the oil tank 3 is arranged in the hull 1, there are multiple oil suction mechanisms, and the multiple oil suction mechanisms are evenly distributed outside the hull 1 Both sides are connected with the oil well pump 2 in the hull 1 through the oil suction pipe 4, and there are two oil well pumps 2 and are connected to both sides of the oil tank 3 through the oil outlet pipe. There are ten oil-absorbing mechanisms in the present invention, and the ten oil-absorbing mechanisms are divided into two groups, and the two groups of oil-absorbing mechanisms are respectively connected with two oil-absorbing pumps 2, that is, each oil-absorbing pump 2 controls five oil-absorbing mechanisms.

[0024] The oil suction mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com