Friction-anti-buckling energy dissipation support

A technology of anti-buckling energy consumption and friction energy consumption, applied in the directions of earthquake resistance, building components, building types, etc., can solve the problems of shortening the maintenance and replacement cycle of anti-buckling supports, increasing the maintenance and use costs of the overall structure in the later period, and reducing the later period. Maintenance and operating costs, increased service life, reduced seismic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation and implementation process of a friction-buckling-resistant energy-dissipating support.

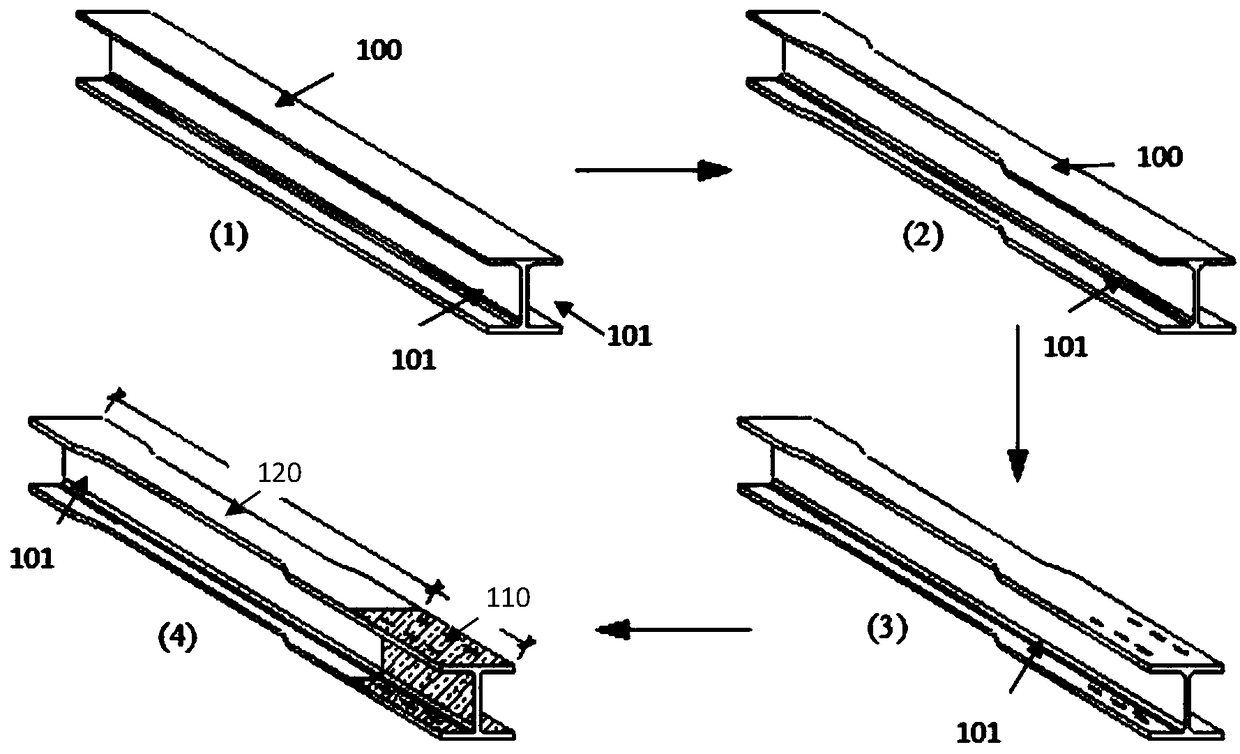

[0041] refer to Figure 1 to Figure 5 As shown, the specific implementation process of a friction-buckling-resistant energy-dissipating support with dual functions of frictional energy dissipation and buckling-resistant energy dissipation is carried out in the following steps:

[0042] The first step is the processing of the inner core 100, that is, the processing of the H-shaped steel inner core.

[0043] Such as figure 1 Shown: First, the flange of the H-shaped steel is cut locally, such as figure 1 As shown in (2), the cutting length is determined according to the design stiffness of the friction-anti-buckling energy-dissipating support, and the cutting width is determined according to the design yield force of the friction-anti-buckling energy-dissipating support, and the H-shaped steel inner core 100 is not cut The section cross-section is not less than twice ...

Embodiment 2

[0057] A friction-buckling-resistant energy-dissipating support.

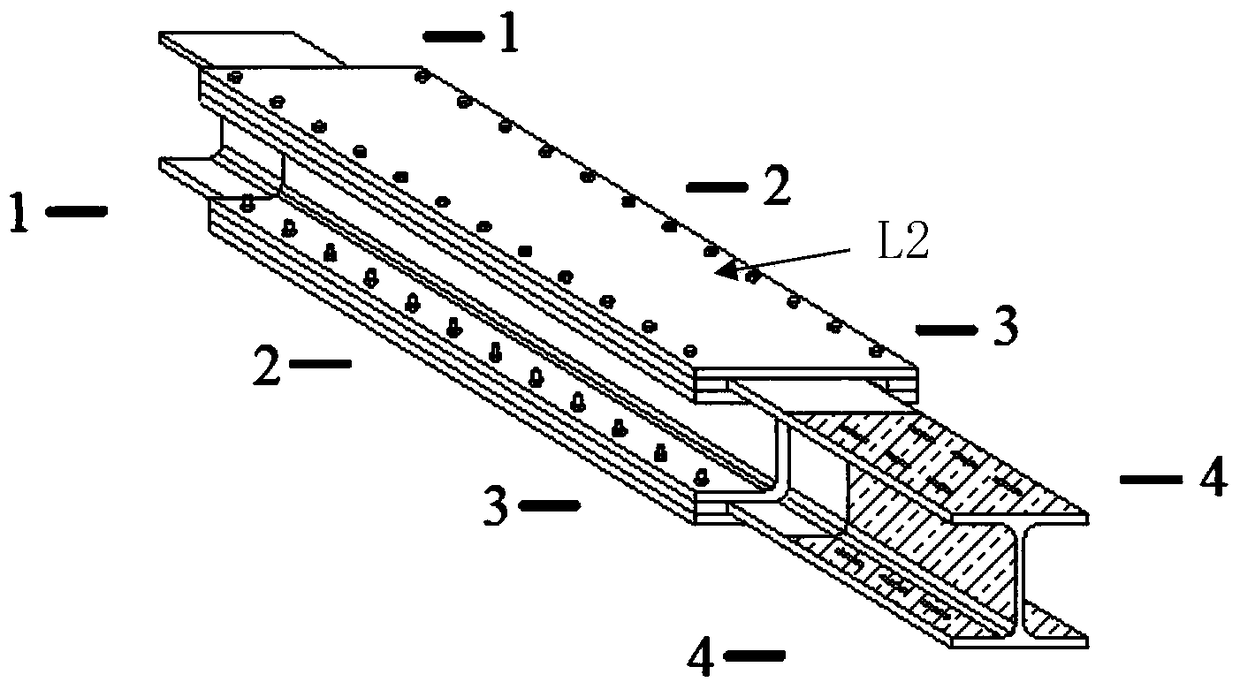

[0058] A friction-buckling-resistant energy-dissipating support, such as Figure 5 As shown, the middle part is the frictional energy dissipation section L1, and the two ends are the anti-buckling energy-dissipating sections L2. 300;

[0059] Such as figure 1 As shown, the inner core 100 is an H-shaped steel that has been processed by partial section flange cutting, and the flange of one end of the uncut section at both ends of the inner core 100 is formed with a number of elliptical long holes, and the end is pasted after sandblasting Friction material, the sandblasting end part is the inner core 110 of the friction energy dissipation section of the inner core 100, and the part flange cutting end part of the inner core 100 is the anti-buckling energy dissipation section of the inner core 100 Core 120;

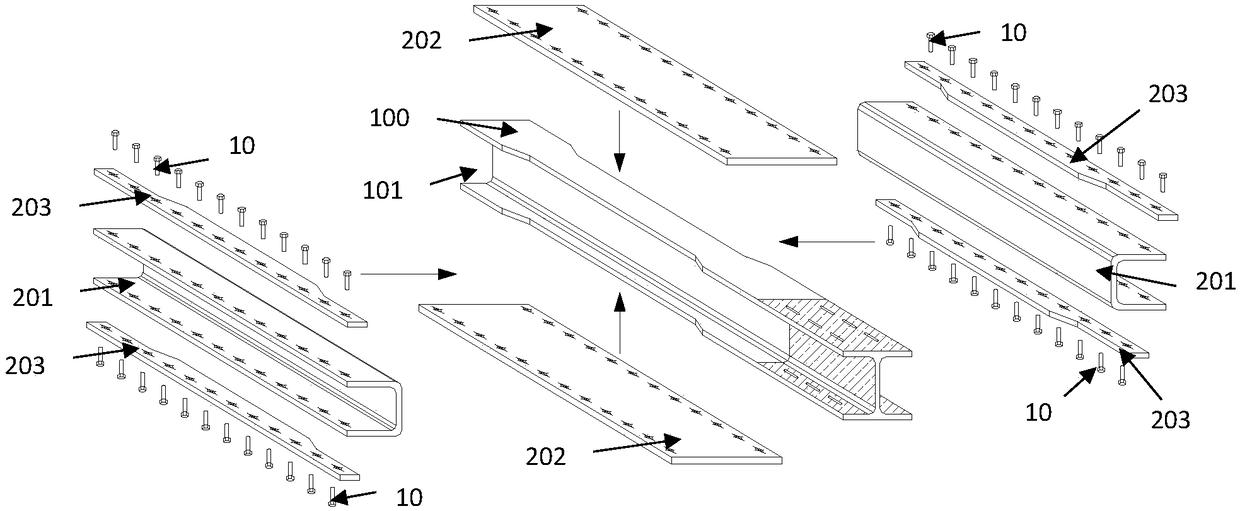

[0060] The anti-buckling constraint member 200 includes two U-shaped channel steels 201, two cover plate...

Embodiment 3

[0068] A friction-buckling-resistant energy-dissipating support.

[0069] In the anti-buckling energy-dissipating section L2, in order to ensure that the lateral expansion of the inner core 100 due to the Poisson effect can be effectively released when it is under pressure, a friction-anti-buckling energy-dissipating support in this example is consistent with that in Embodiment 2 Further, the thickness of the pad 203 and the height of the U-shaped channel steel 201 keep the gap between the inner core 100 and the anti-buckling constraining member 200 at 1mm-2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com