Slide ring seal arrangement of a hydrodynamic retarder, and hydrodynamic retarder

A mechanical seal device and hydraulic reducer technology, applied in the field of hydraulic reducer, can solve the problems of mechanical seal damage, lack of lubricating medium, failure, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

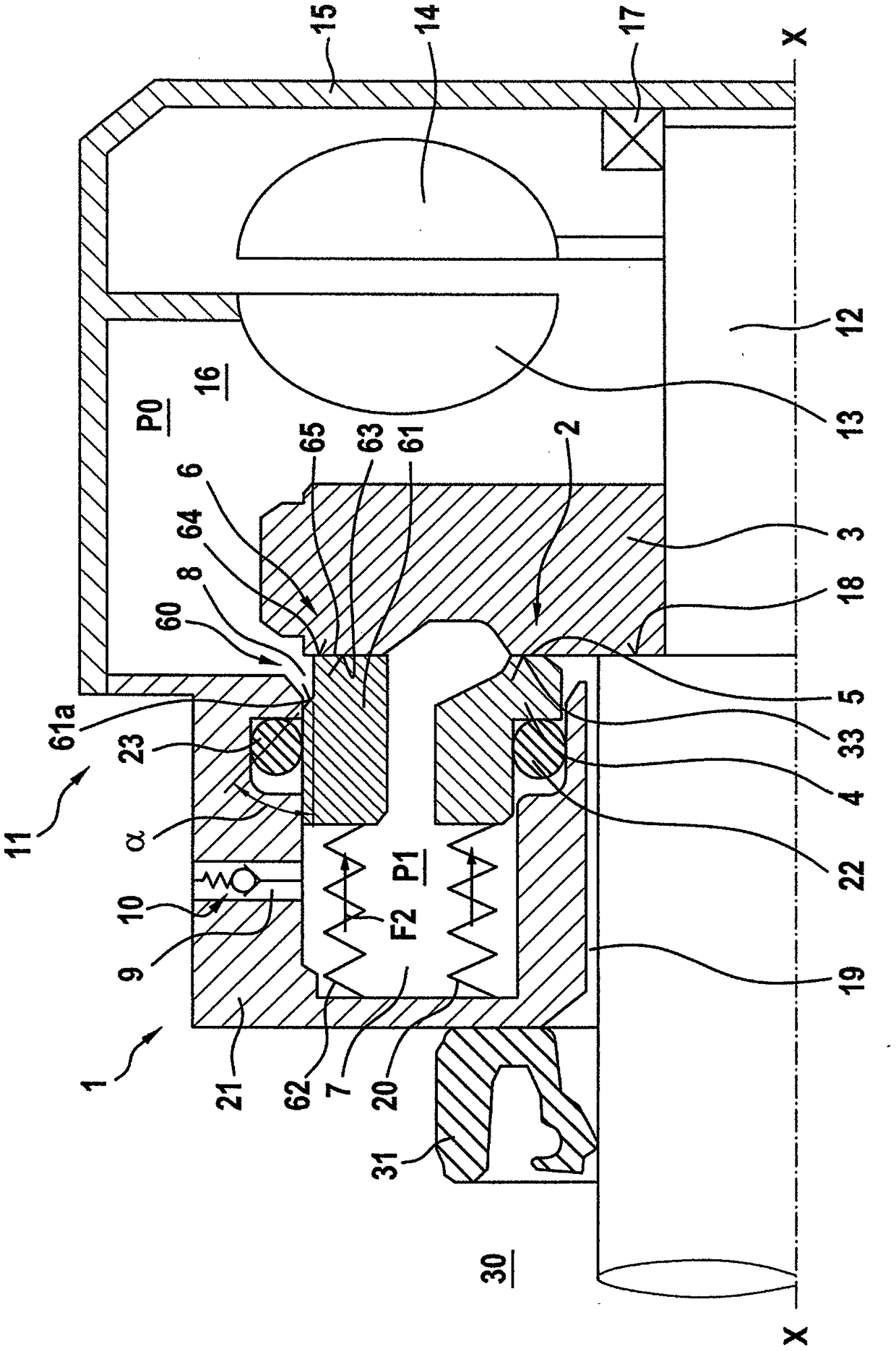

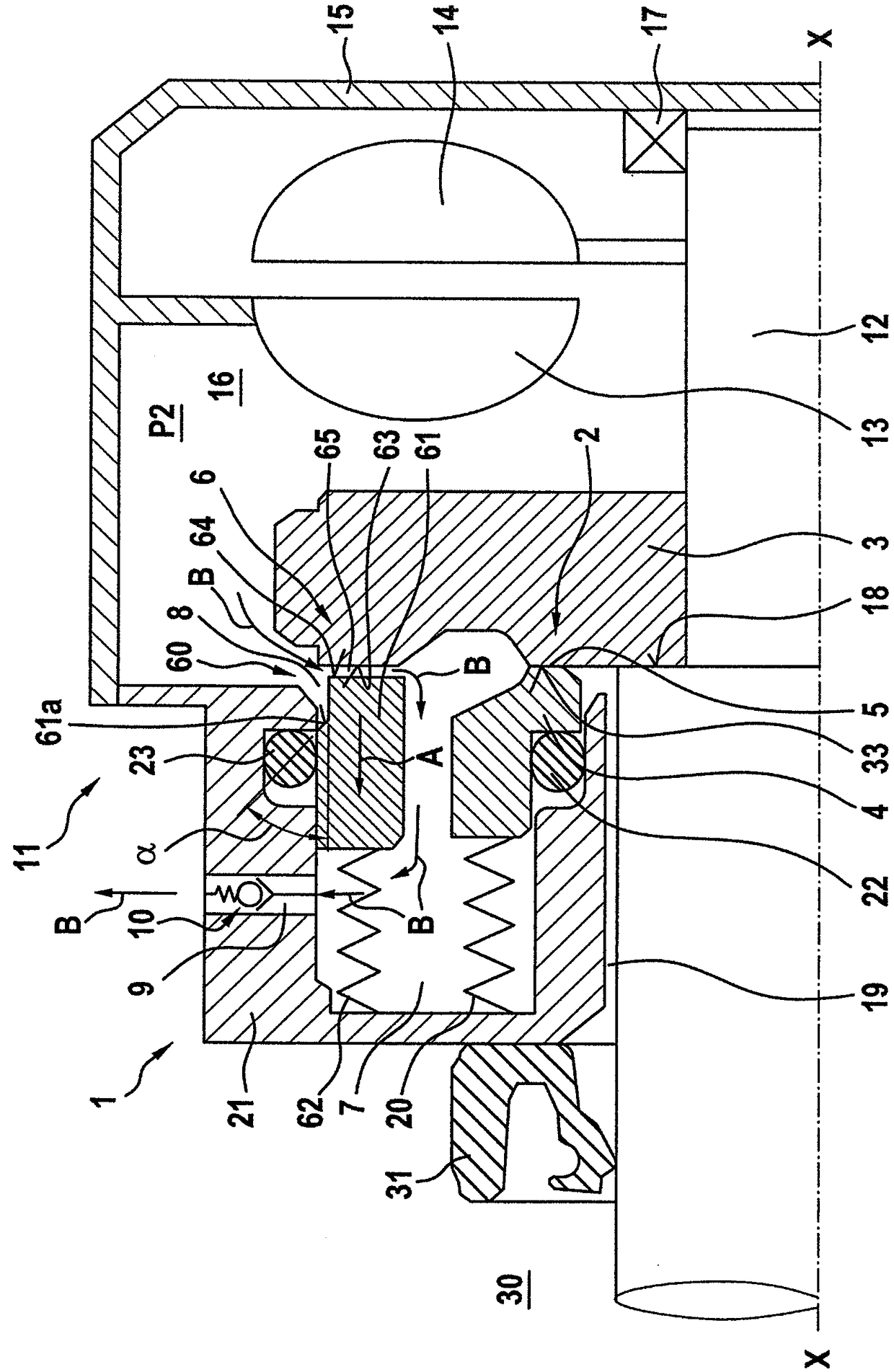

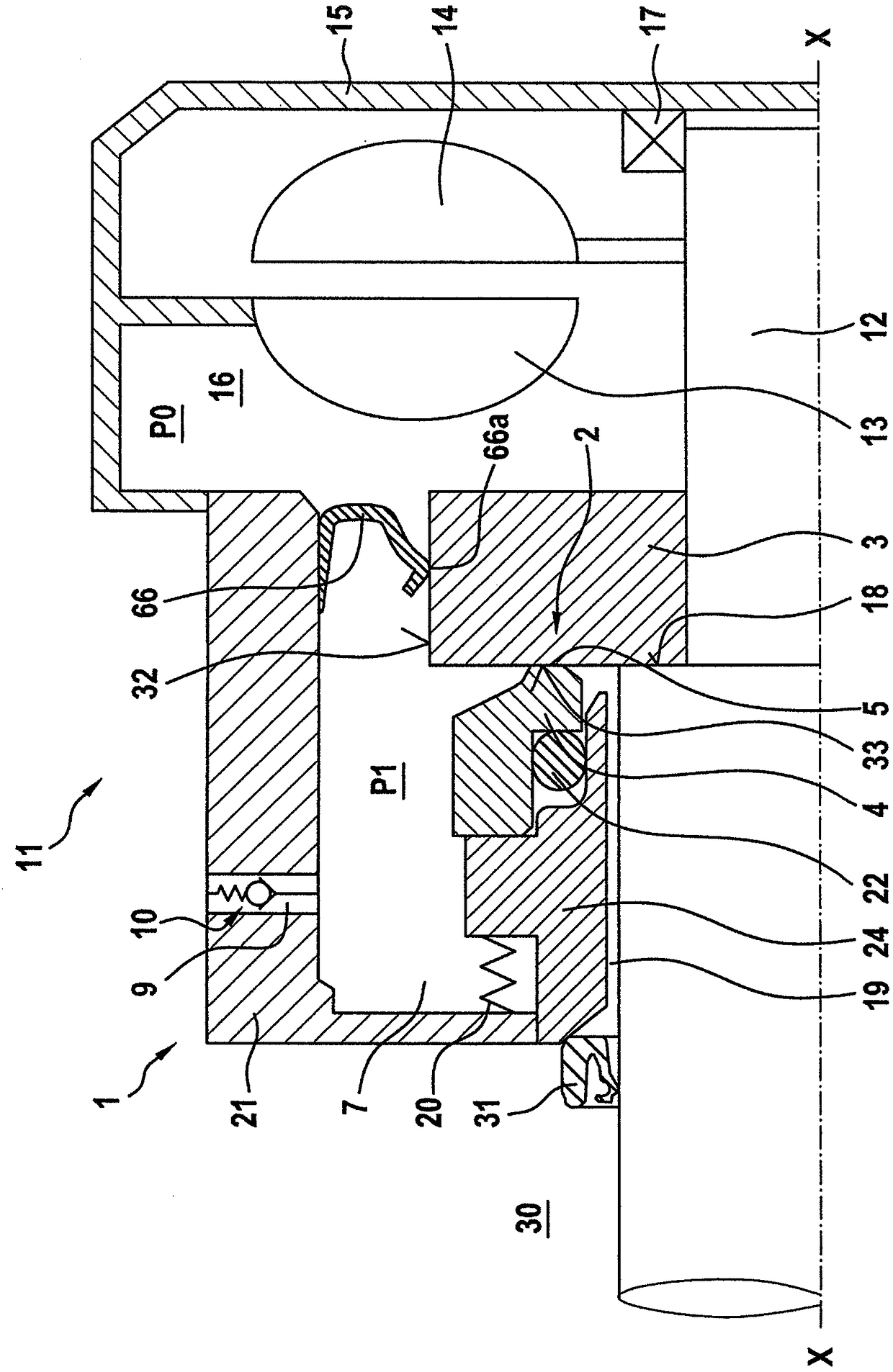

[0069] Refer to the following figure 1 and figure 2 The mechanical seal device 1 and the hydraulic retarder 11 according to the first preferred embodiment of the present invention will be described in detail.

[0070] figure 1 A sectional view of a reducer 11 is shown, comprising a reducer shaft 12 , a stator 13 , a rotor 14 and a reducer housing 15 . The gear unit housing 15 encloses a gear unit working chamber 16 . The stator 13 is fastened here to the gear unit housing 15 . The rotor 14 is connected to the reducer shaft 12 . Reference numeral 17 denotes a bearing (cantilever support) on which the reducer shaft 12 is mounted.

[0071] Hydrodynamic retarders are used, for example, in vehicles, especially for vehicles such as trucks or buses. Here, the braking work of the retarder is performed by filling the retarder working chamber 16 with liquid (for example oil), ie converted into heat. After a successful braking operation, the fluid is then drained from the retarde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com