System for measuring frequency conversion efficiency of laser frequency doubling crystal and performance characterizing method

A frequency conversion and efficiency measurement technology, applied in measurement devices, optical instrument testing, optics, etc., can solve problems such as the inability to accurately characterize the frequency conversion efficiency of KDP crystals, achieve the effect of simple and efficient test methods, and meet the measurement range and accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and a specific embodiment.

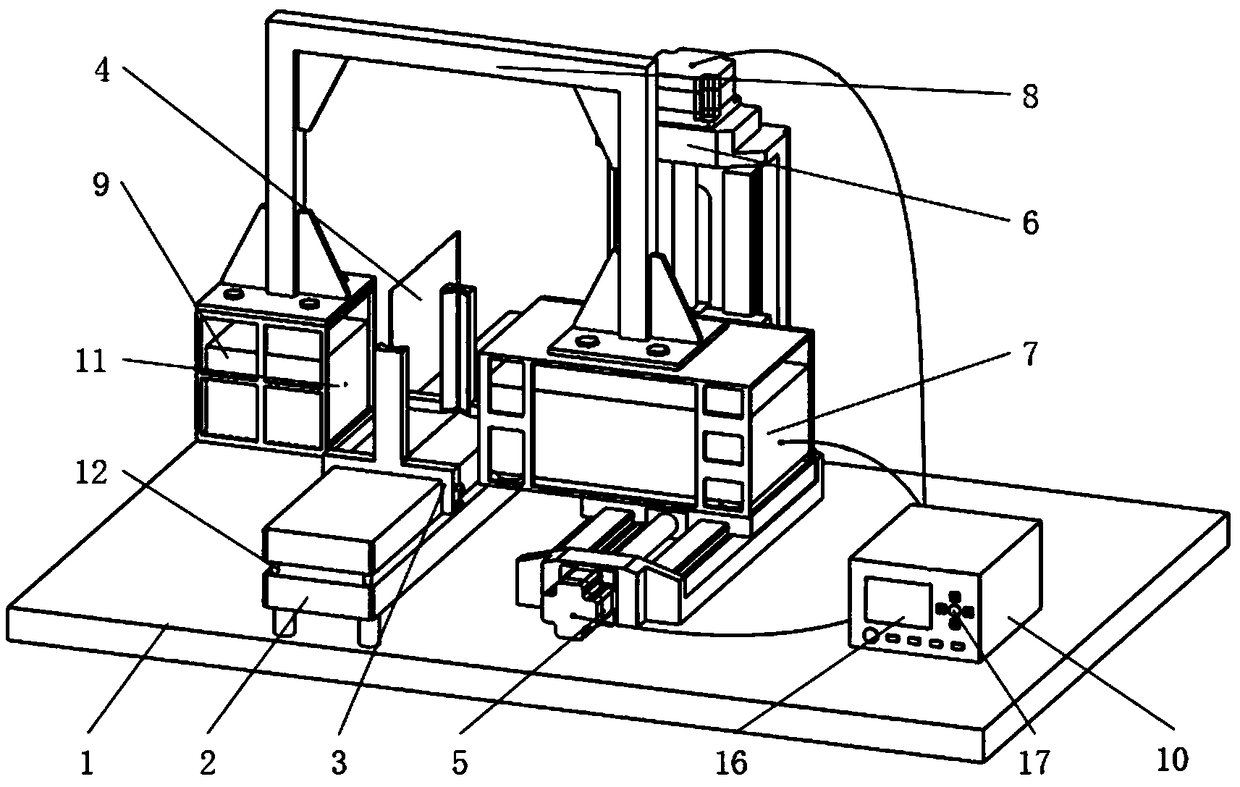

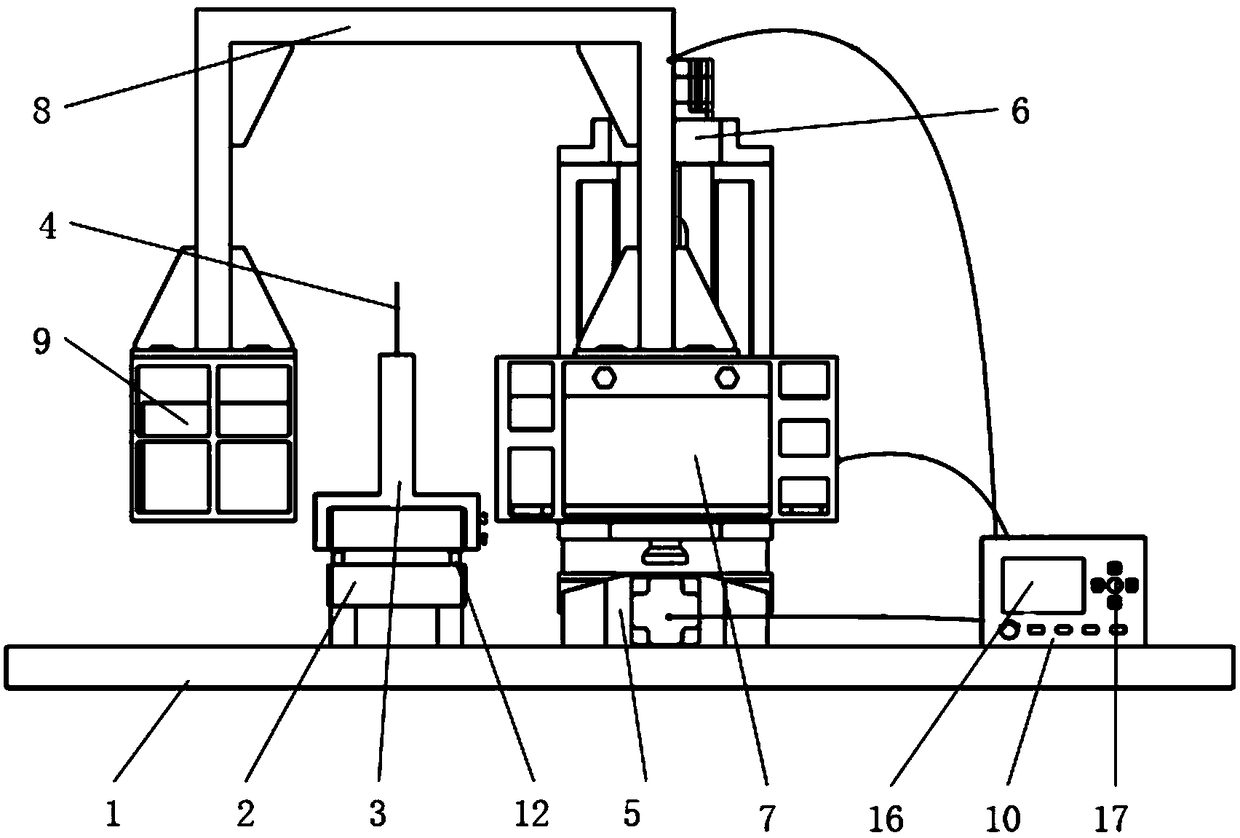

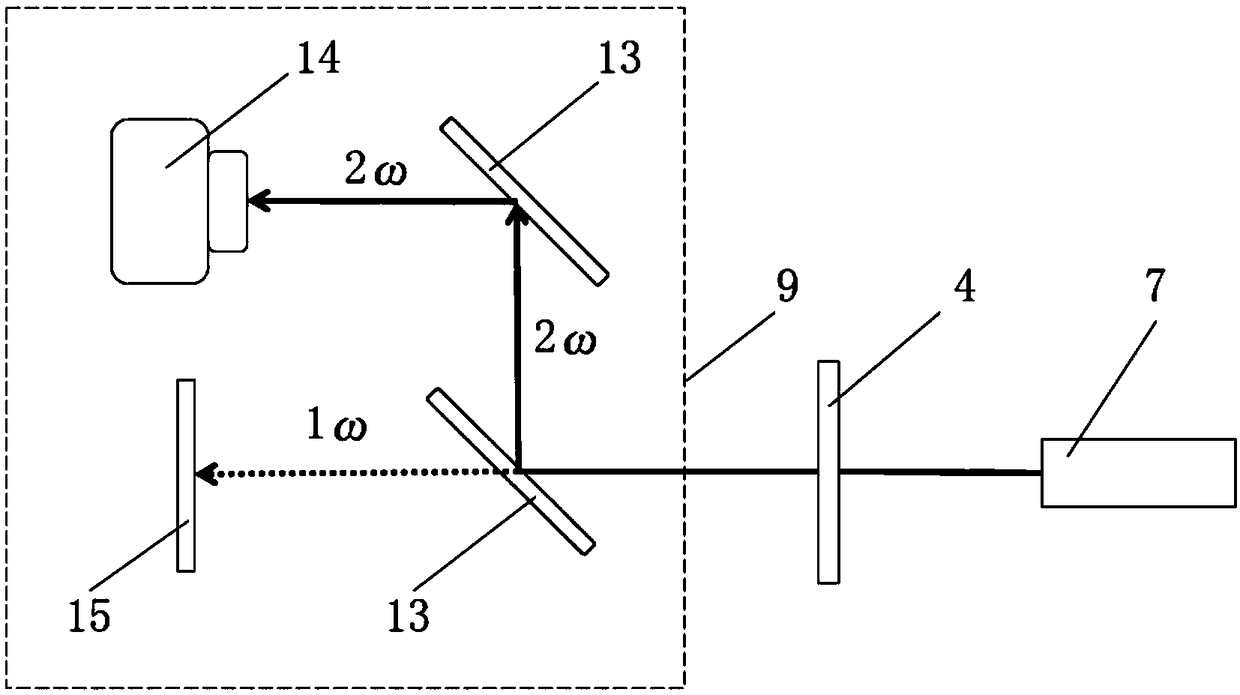

[0036] like figure 1 and 2 As shown, the present invention is a laser frequency doubling crystal frequency conversion efficiency measurement system, which mainly includes a high rigidity substrate 1, a loading plate 2, a crystal fixing frame 3, a KDP crystal element 4, an X-direction precision electric translation stage 5, and a Y-direction Precision electric translation stage 6, laser 7, U-shaped adapter frame 8, laser receiver 9, controller module 10, etc.

[0037] in:

[0038] The high-rigidity substrate 1 is a rectangular high-flatness steel plate with a size of 1800mm*1200mm*10mm, which is used to install and support the loading plate 2 and the X-direction precision electric translation table 5;

[0039] The loading plate 2 is a loading platform constructed of stainless steel, and the four legs are respectively fixed on the h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap