A kind of kelp paper solid dispersion and its preparation method and application

A technology of solid dispersion and paper paper, which is applied in the direction of non-active ingredient medical preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problem of large amount of surfactant used and unsatisfactory dissolution results , safety concerns and other issues, to achieve the effect of improving dissolution rate, realizing automatic control and promoting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

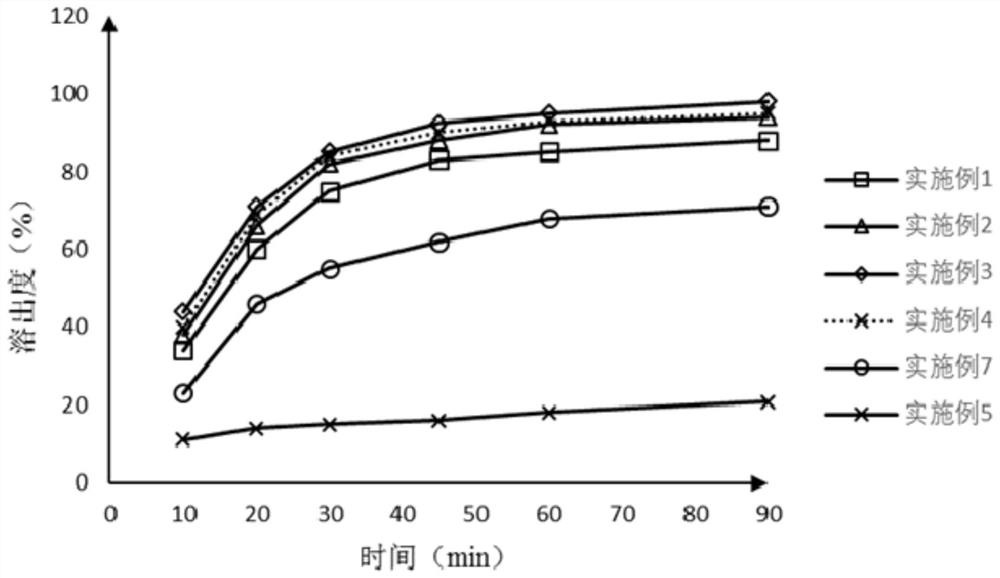

Examples

Embodiment 1

[0037] Melaleuca paper solid dispersion

[0038] The preparation method of this kelp paper solid dispersion is as follows:

[0039] 1. Weigh 5g kelp paper, 10g HPMC, 5g EPO, sieve and mix thoroughly.

[0040] 2. Set the temperature of the twin-screw hot-melt extruder (conventional equipment, the same below) to 180°C, start the screw after the machine reaches the preset temperature, set the screw speed to 80 rpm, and put the mixture in the previous step at a uniform speed Pour it into the feed port of a twin-screw hot-melt extruder, heat-melt and extrude it and extrude it in a strip shape. After the extrudate is cooled, it is crushed and passed through a 60-mesh sieve to obtain a solid dispersion powder.

Embodiment 2

[0042] Melaleuca paper solid dispersion

[0043] The preparation method of this kelp paper solid dispersion is as follows:

[0044] 1. Weigh 5g kelp paper, 7.5g HPMC, 7.5g EPO, sieve and mix thoroughly.

[0045]2. Set the temperature of the twin-screw hot-melt extruder to 180°C, start the screw after the machine reaches the preset temperature, set the screw speed to 80 rpm, and pour the mixture in the previous step into the twin-screw hot-melt extruder at a constant speed In the feeding port of the machine, it is extruded in a strip shape after being hot-melted and extruded. After the extruded product is cooled, it is crushed and passed through a 80-mesh sieve to obtain a solid dispersion powder.

Embodiment 3

[0047] Melaleuca paper solid dispersion

[0048] The preparation method of this kelp paper solid dispersion is as follows:

[0049] 1. Weigh 5g kelp paper, 5g HPMC, 10g EPO, sieve and mix thoroughly.

[0050] 2. Set the temperature of the twin-screw hot-melt extruder to 180°C, start the screw after the machine reaches the preset temperature, set the screw speed to 80 rpm, and pour the mixture in the previous step into the twin-screw hot-melt extruder at a constant speed In the feeding port of the machine, it is extruded in a strip shape after being hot-melted and extruded. After the extruded product is cooled, it is crushed and passed through a 80-mesh sieve to obtain a solid dispersion powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com