Dye mixing device for garment production

A mixing device and dye technology, applied in the field of garment production, can solve the problems of insufficient stirring effect, restricting dyeing effect, and insufficient dispersion effect of dye components, and achieve the effect of improving the degree of stirring and mixing and improving the mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

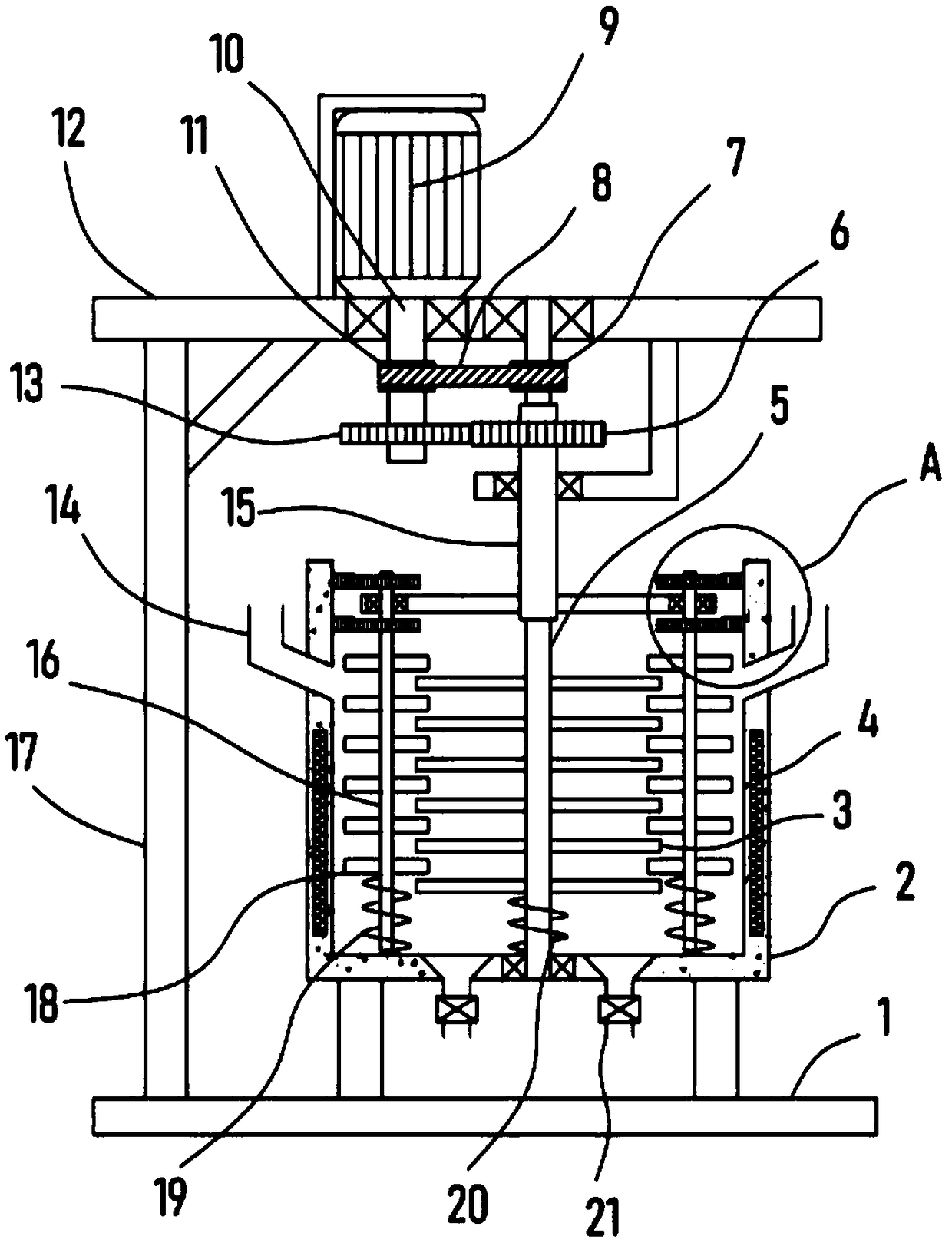

[0022] see Figure 1-3 , a dye mixing device for garment production, comprising a support base plate 1, a support column 17 is vertically fixed on the support base plate 1, a horizontal plate 12 is fixed horizontally on the top of the support column 17, a mixing bucket 2 is fixedly installed on the support base plate 1, and Bucket 2 is an open barrel-shaped structure, which is used to hold dyes to be stirred. Further, a feed pipe 14 is provided on the upper side wall of the mixing tank 2, and a discharge pipe 21 is installed vertically at the bottom of the mixing tank 2, and a valve is installed on the discharge pipe 21. By adding dye into the mixing tank 2 , the stirred and mixed dye can be discharged out of the mixing tank 2 through the discharge pipe 21 .

[0023] The driving motor 9 is installed on the horizontal plate 12, the output shaft of the driving motor 9 is coaxially fixed with the driving shaft 10, the driving gear 13 is coaxially fixed on the driving shaft 10, t...

Embodiment 2

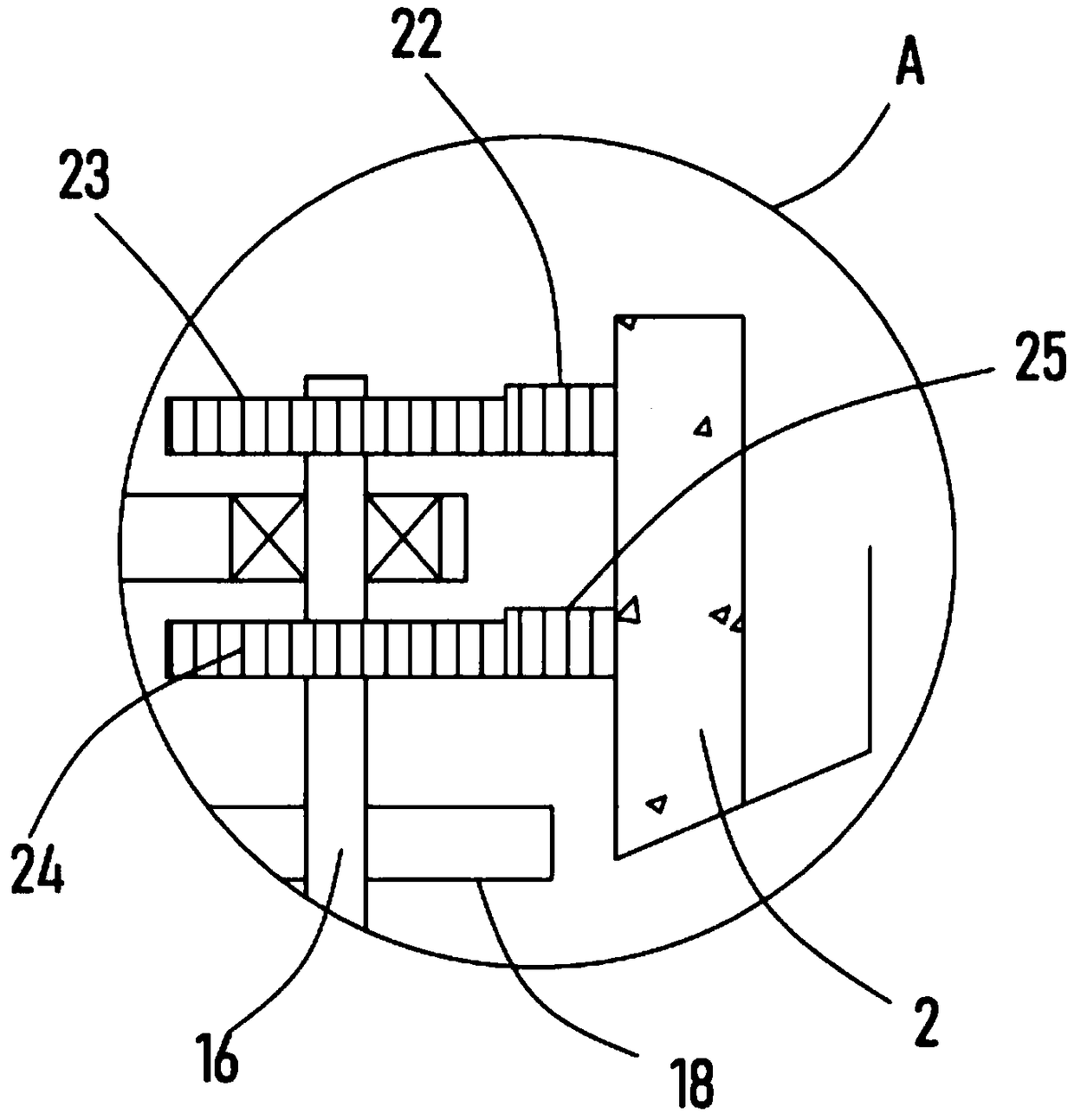

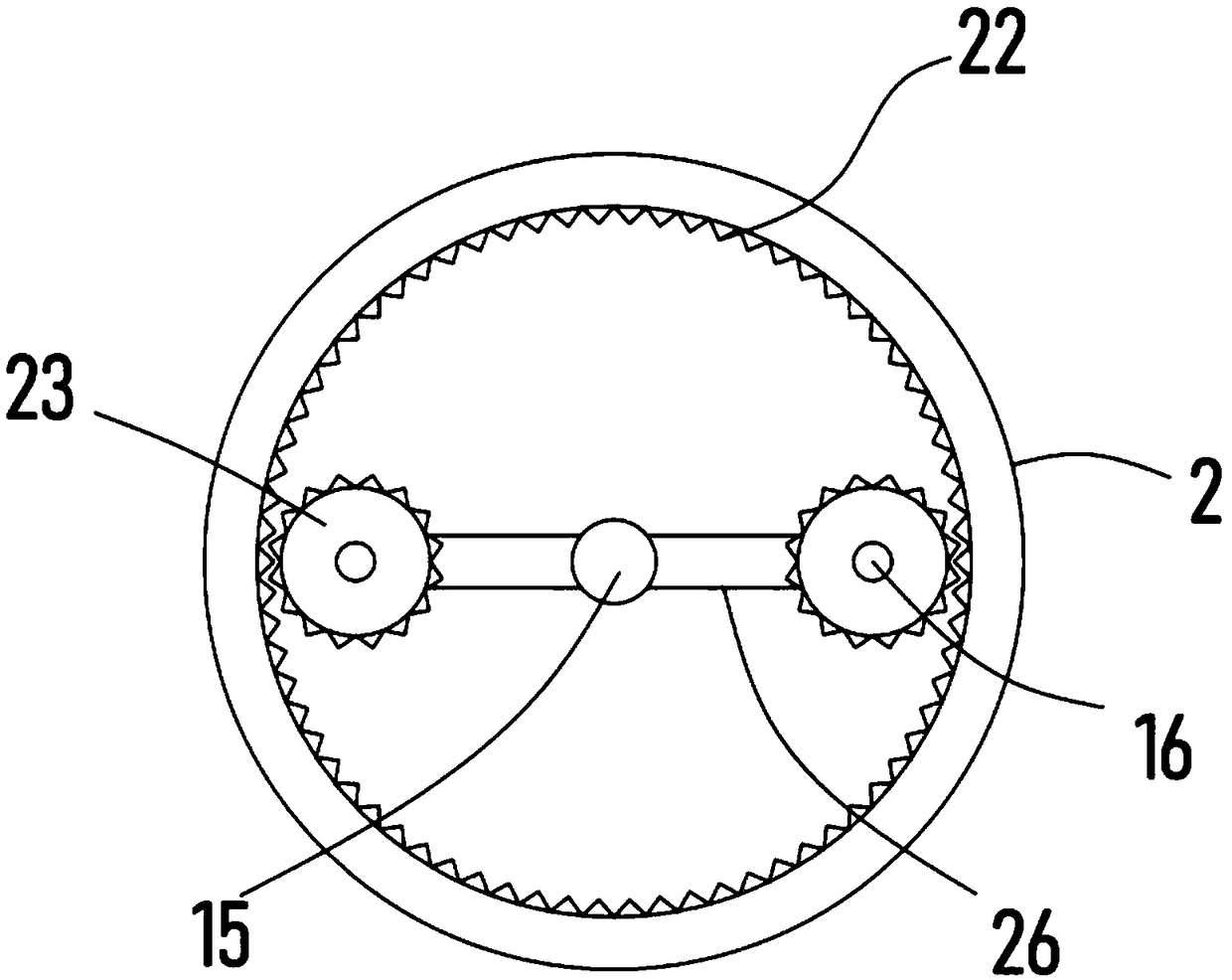

[0029] On the basis of Embodiment 1, in addition, the inner wall of the mixing tank 2 is fixed with an inner ring gear I22, the surface of the stirring shaft 16 is fixed with a transmission gear I23 meshing with the inner ring gear I22, and the inner wall of the mixing tank 2 is fixed with an inner ring gear II25 , the surface of the stirring shaft 16 is fixed with a transmission gear II24 meshing with the inner ring gear II25. During the process of the connecting rod 26 driving the stirring shaft 16 to rotate, the transmission gear I23 on the stirring shaft 16 is engaged with the inner ring gear I22. The transmission gear II24 and the ring gear II25 are meshed for transmission, so that the stirring shaft 16 drives the rotating blade II18 to rotate, and then the dye in the mixing barrel 2 is fully stirred and mixed.

[0030] Further, the surface of the lower end of the driven shaft 5 is fixed with a helical blade II20, the helical blade II20 rotates with the driven shaft 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com