Cyclone separator for starch washing

The technology of a cyclone separator and a cyclone is applied in the direction of a cyclone device, a device in which the axial direction of the cyclone can be reversed, etc., and can solve the problems of a large washing and separating group system, unable to meet production needs, and complex production process. , to simplify the washing and separation process, improve the washing effect and separation effect, and improve the purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

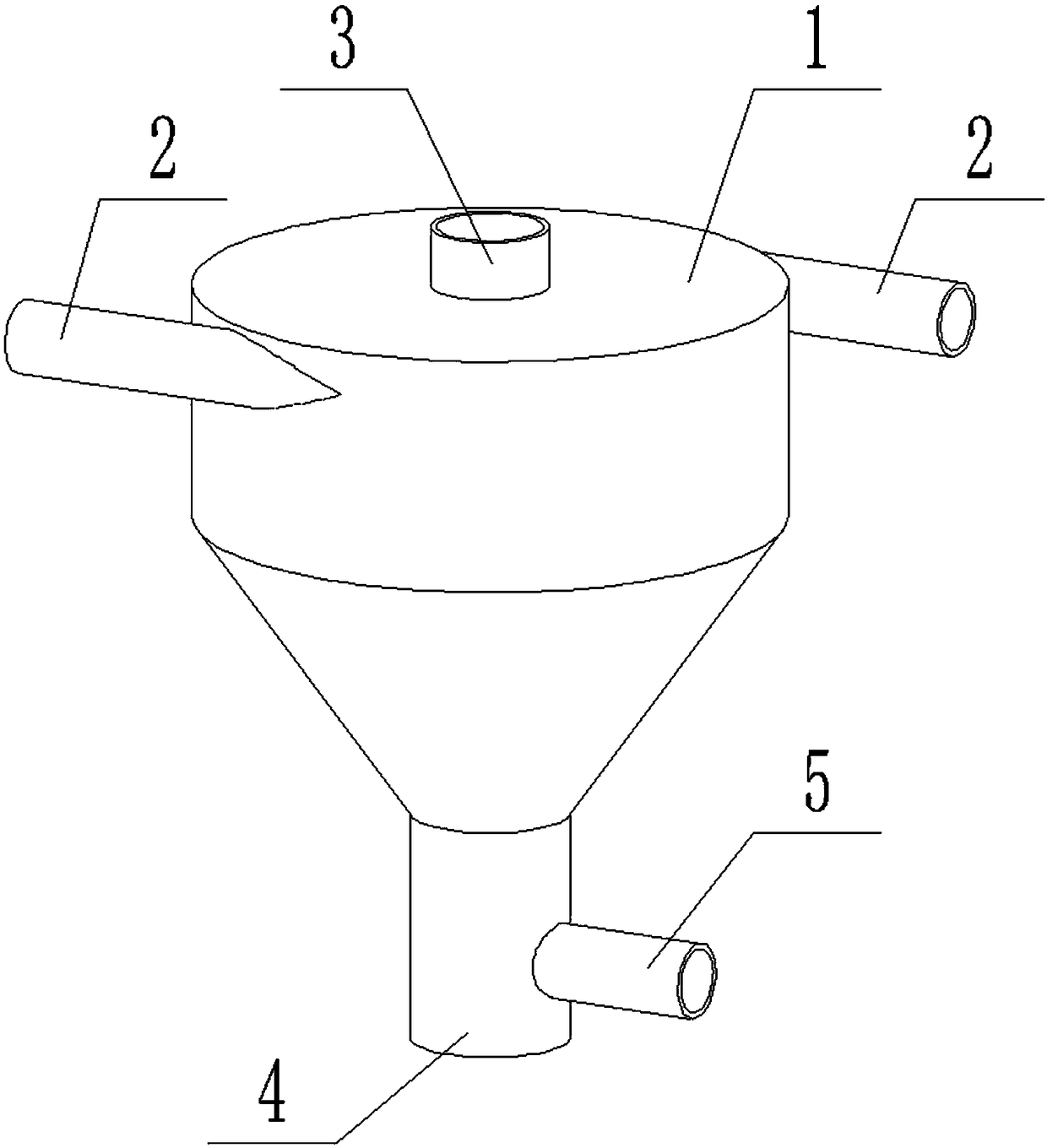

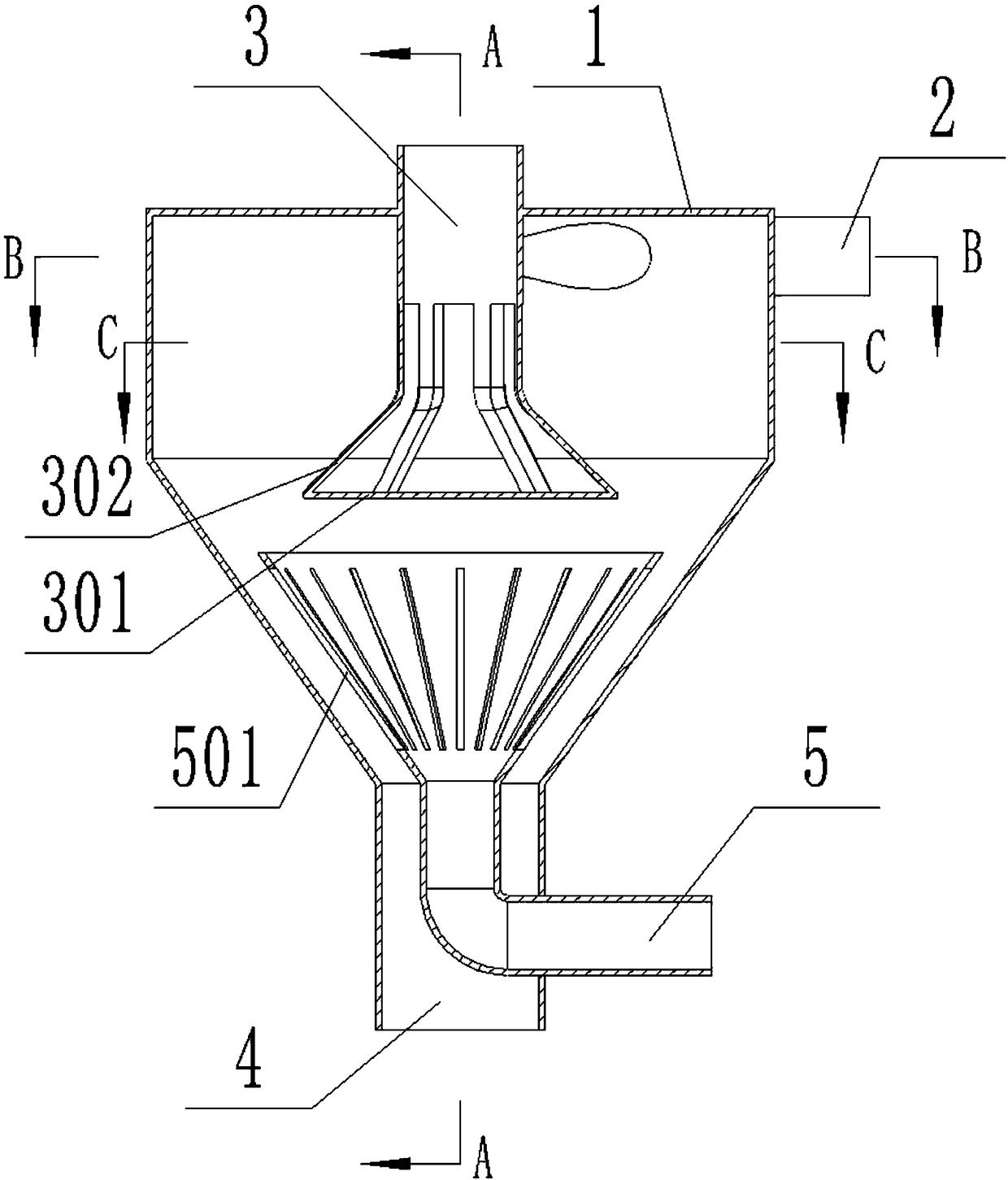

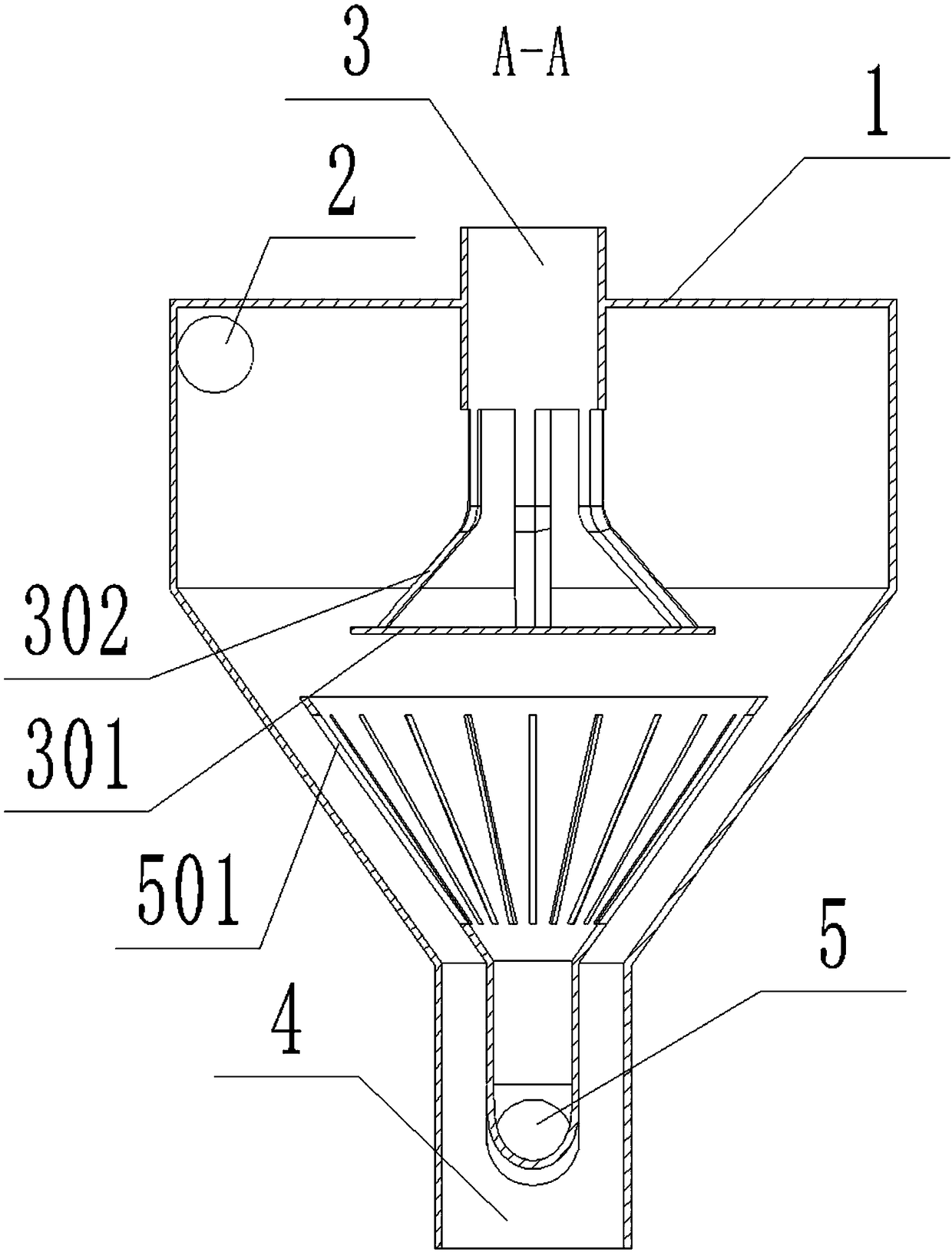

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The present invention provides a cyclone separator for starch washing, including: a cyclone cylinder 1, a raw material inlet 2, an overflow port 3, a separator plate 301, a screening plate 302, a dense medium bottom flow port 4, and a return port 5 and a splitter plate 501; a group of raw material inlets 2 are fixedly connected to the front and rear end surfaces of the cyclone cylinder 1; a group of overflow ports 3 are fixedly connected to the top of the cyclone cylinder 1; the bottom of the cyclone cylinder 1 is fixed A set of dense medium bottom flow ports 4 is connected; a set of return flow ports 5 is fixedly connected to the right side of the heavy medium bottom flow port 4 .

[0033] Wherein, the two groups of raw material inlets 2 are installed tangentially to the cyclone cylinder 1, and the centers of the two groups of raw material inlets 2 are symmetrically distributed.

[0034] Wherein, a component l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com