High-strength steel automobile outer cover assembly and manufacturing method thereof

A technology for an outer cover and a manufacturing method, which is applied to vehicle parts, transportation and packaging, etc., can solve the problems of difficulty in ensuring the dimensional accuracy of the parts, the reduction of stamping and forming performance, and the large forming force, so as to shorten the heating time and improve the strength. , the effect of less oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, spring steel is used as a raw material for processing to form a high-strength steel automobile outer cover assembly.

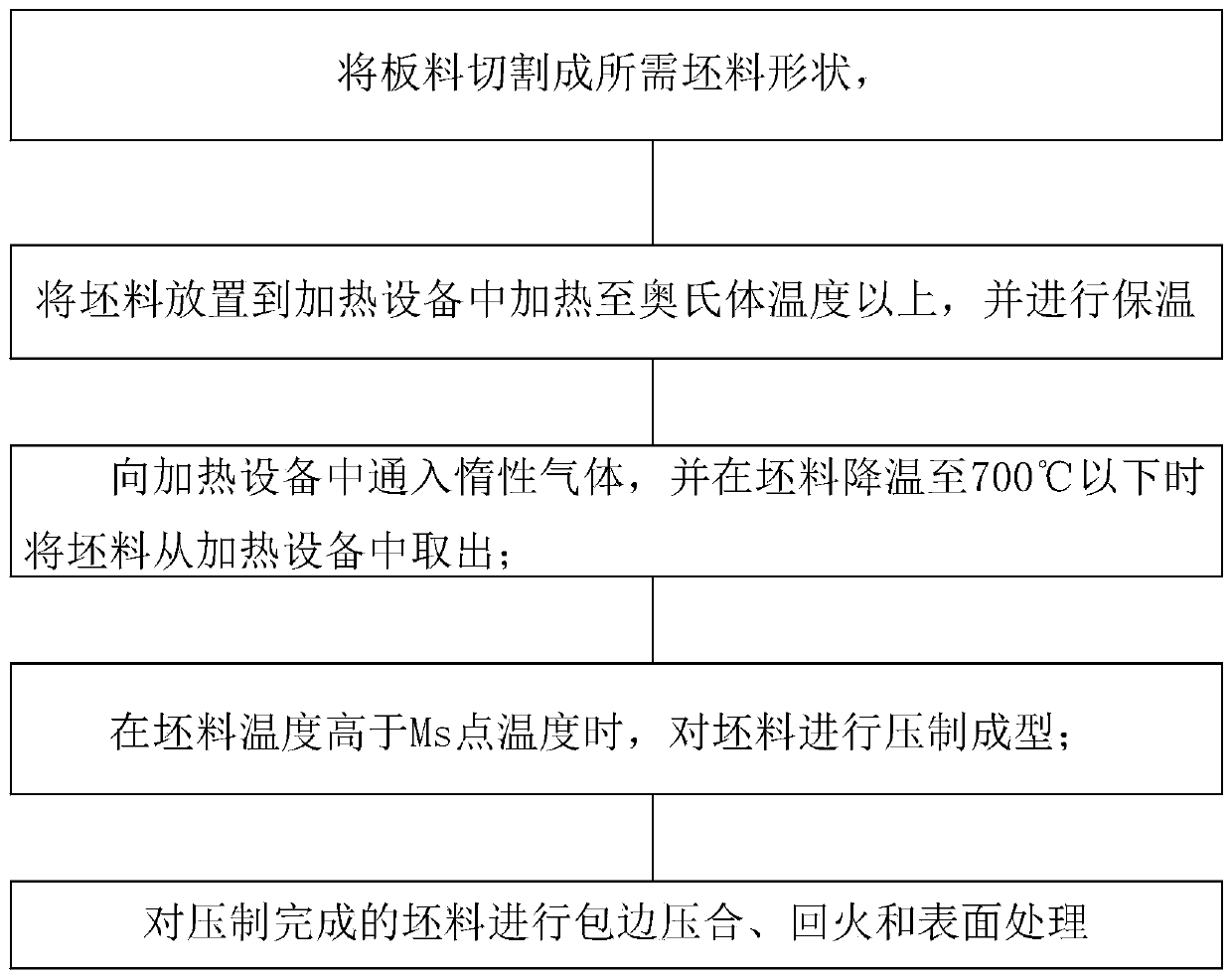

[0036] Such as figure 1 As shown, the present invention provides a kind of manufacturing method of high-strength steel automobile outer cover assembly, comprising:

[0037] First, the sheet is cut into the desired blank shape. The plate is cold-rolled or spring steel after cold-rolled annealing and pickling. It should be noted that, generally, the automobile outer cover assembly includes an outer cover and an inner cover, the blank is used to form the outer cover, and the inner panel is usually formed by a steel material through a hot forming process or a cold forming process production. Moreover, the thickness of the sheet material is 0.3-0.7mm, preferably 0.4mm-0.55mm, so that the weight of the automobile body cover can be greatly reduced. Further, before the sheet is cut, the surface of the sheet is subjected to pre-processing...

Embodiment 2

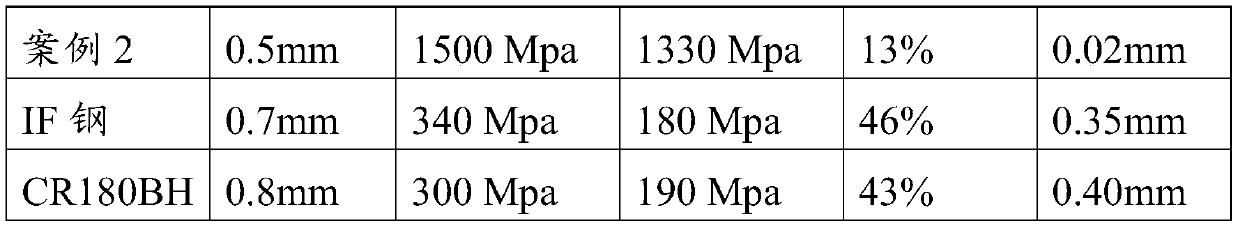

[0076] The difference between this embodiment and Embodiment 1 is that this embodiment uses medium manganese steel as the raw material for processing to form a high-strength steel automobile outer cover assembly, and the blank made of medium manganese steel is used. The heating temperature in the heating equipment is It only needs to be around 800°C to achieve complete austenitization of steel, which is 100°C-150°C lower than the heating temperature of hot-formed steel, and the setting temperature of the heating furnace is lower, saving energy.

[0077] The present embodiment will be described in detail below with two specific implementation processes.

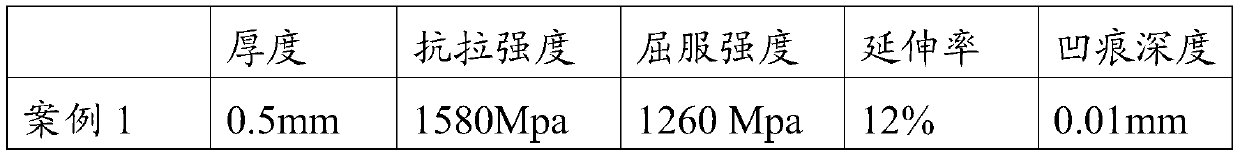

[0078] The part prepared in Case 1 is an integral door panel, and the specific operation is as follows:

[0079] 1. Use medium manganese steel with a thickness of 0.55mm and cold-rolled, annealed and pickled. Its components include: C: 0.12%, Mn: 4.8%, Si: 0.2%, P<0.02%, S<0.02%. The Ms point temperature is 240°C.

[0080] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com