Pin lifting device

A technology of a pin and a lifting device, which is applied in the field of tooling equipment, can solve the problem that a pin with a larger diameter or a pin and a pin hole cannot be effectively removed, and achieves the effect of simple structure, high efficiency and avoiding device scrapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

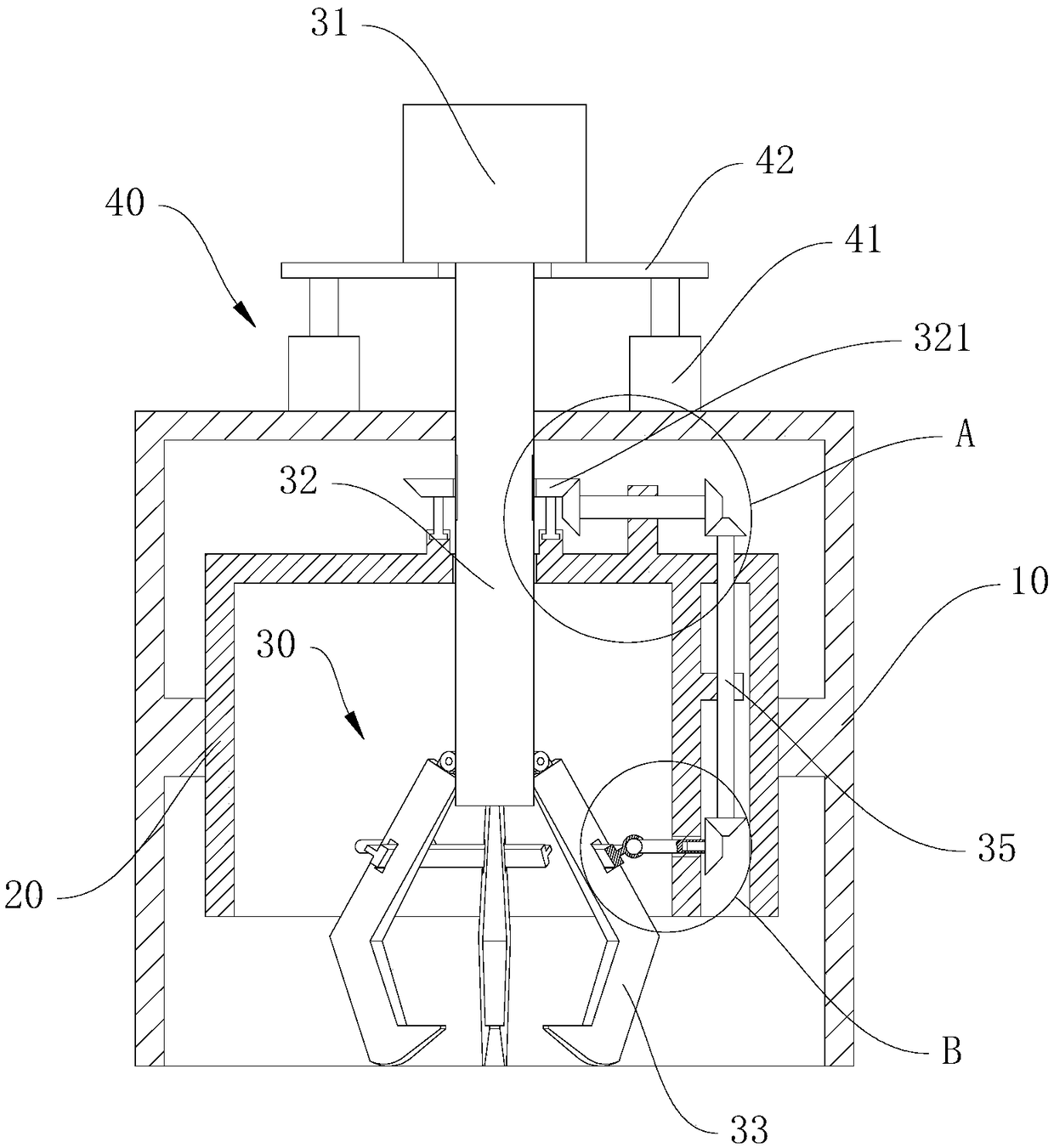

[0034] Such as figure 1 As shown, a pin removing device provided in an embodiment of the present invention includes:

[0035] The outer casing 10 is a barrel-shaped structure with a columnar bottom and an opening, and has a storage cavity;

[0036]The lifting device 40 includes a lifting shaft 32 and a lifting device. The lifting device is arranged on the outer casing 10 to drive the lifting shaft 32 to move up and down. The outer casing 10 is provided with a storage hole for accommodating the lifting The shaft 32 passes through, and the lifting device 40 is an electric telescopic rod 41 or a cylinder. The electric telescopic rod 41 is used as an example in this embodiment. A lifting plate 42 is connected to the upper end of the electric telescopic rod 41, and the lifting shaft 32 is connected to the mounting plate. When the rod 41 drives the lifting plate 42 to move, it drives the lifting shaft 32 to move up and down;

[0037] The grabbing device includes several grabbing c...

Embodiment 2

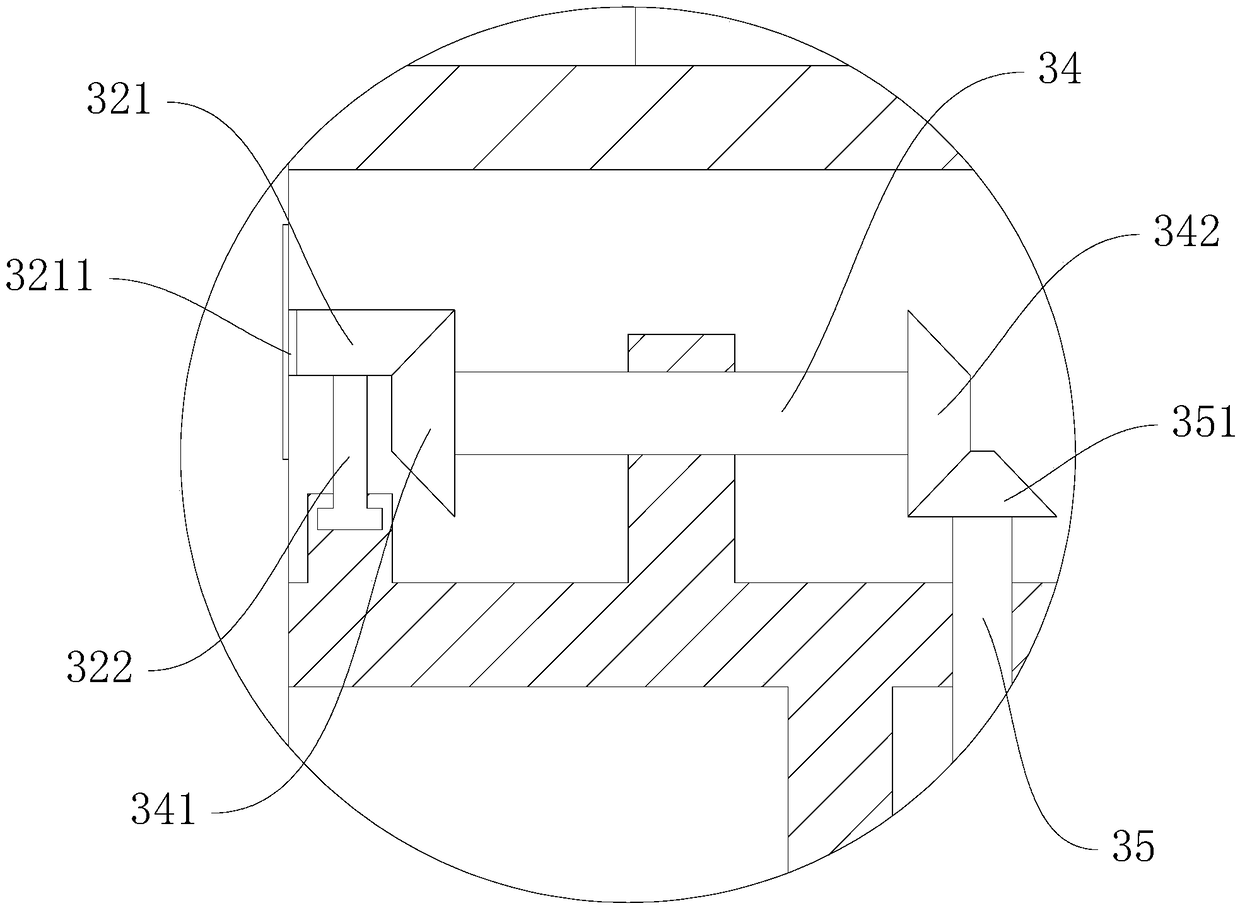

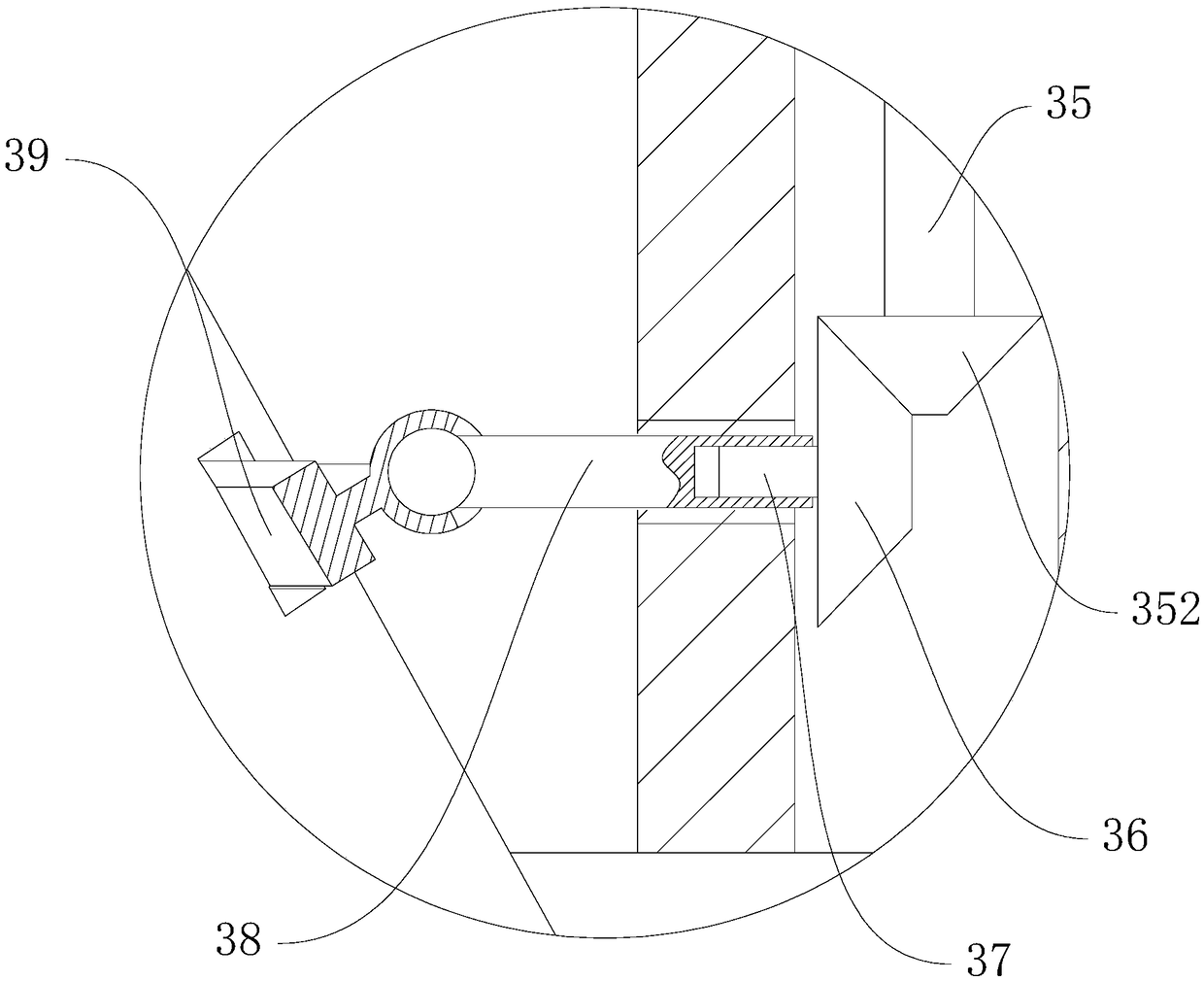

[0039] On the basis of Example 1, as Figure 1-6 As shown, because some pins are affected by the environment of the use occasion, such as rust or a relatively large interference, resulting in a relatively large force between the pin and the pin hole, at this time only rely on the friction between the grasping claw 33 and the pin It is still difficult to pull out the pin, so this embodiment also includes a grinding device 30 and an inner casing 20, the inner casing 20 is fixedly arranged in the outer casing 10, and there is a gap between the inner casing 20 and the outer casing 10. A certain gap, the peripheral side of the inner casing 20 is fixedly connected by a fixed block, such as figure 1 As shown, the grinding device 30 includes a motor 31, a driving bevel gear 321, a first connecting shaft 34, a second connecting shaft 35, a pushing connecting rod 38, a pushing spline shaft 37 and several driving rings 39, the hook portion A cutter 331 is provided, and the cutter 331 ca...

Embodiment 3

[0042] In another embodiment, in order to prevent the motor 31 from being directly lifted, the pulling force of the lifting shaft 32 on the main shaft of the motor 31 will cause damage to the motor 31. Therefore, as Figure 7 and Figure 8 As shown, the outer casing 10 is provided with a support arm 44, and the lifting shaft 32 is provided with a lifting plate 42, and the lifting plate 42 and the lifting device can be arranged along the axis perpendicular to the lifting shaft 32. Relative rotation in the plane, the two sides of the motor 31 are provided with a support slide bar 45, one end of the support slide bar 45 is fixedly connected to the motor 31, and the other end can be moved up and down along the extension direction of the lifting shaft 32 Slidably arranged on the support arm 44 .

[0043] Specifically, the lifting plate 42 is provided with an annular chute coaxial with the lifting shaft 32, and the output end of the lifting device is provided with a lifting slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com