Spraying sterilization equipment for injection packing bottles

A technology for spray sterilization and bottle packaging, which is applied in the directions of packaging sterilization, packaging, transportation and packaging, can solve the problems of puncturing the bottom of the packaging bottle, affecting the sterilization effect, and not designing a buffer protection structure, and achieves a simple mechanism. , Improve the effect of sterilization and cleaning, and facilitate the effect of plugging and positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

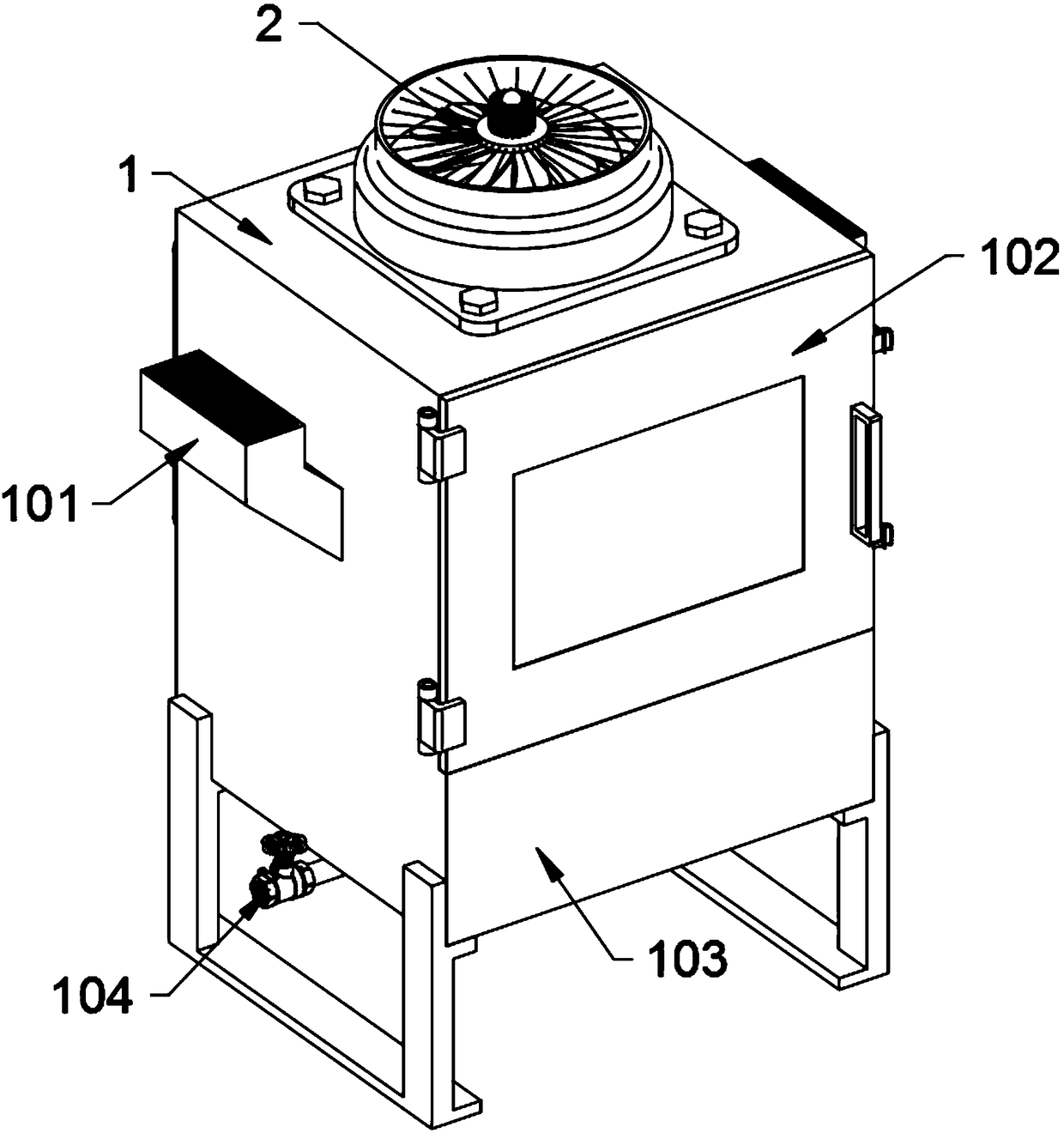

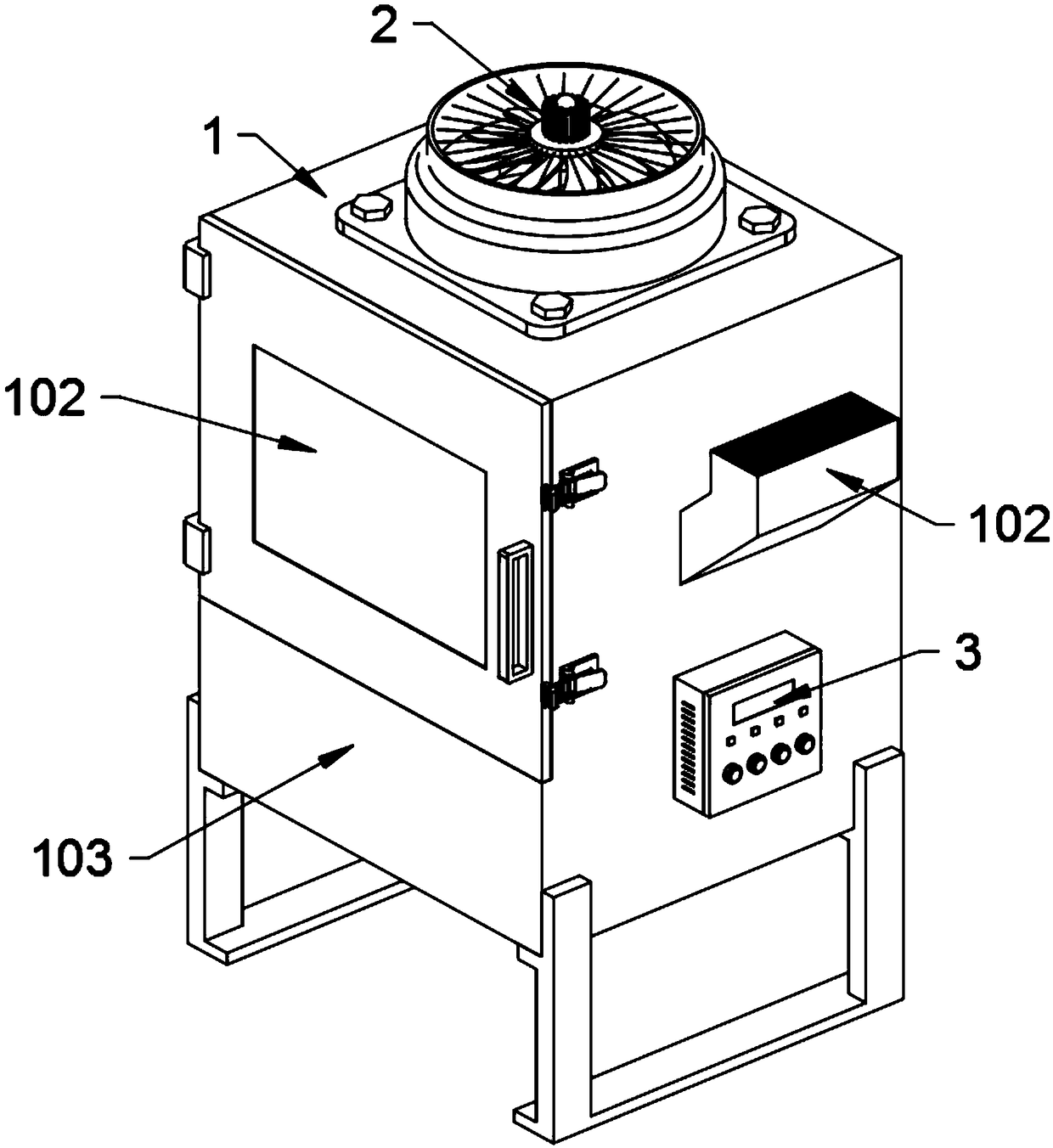

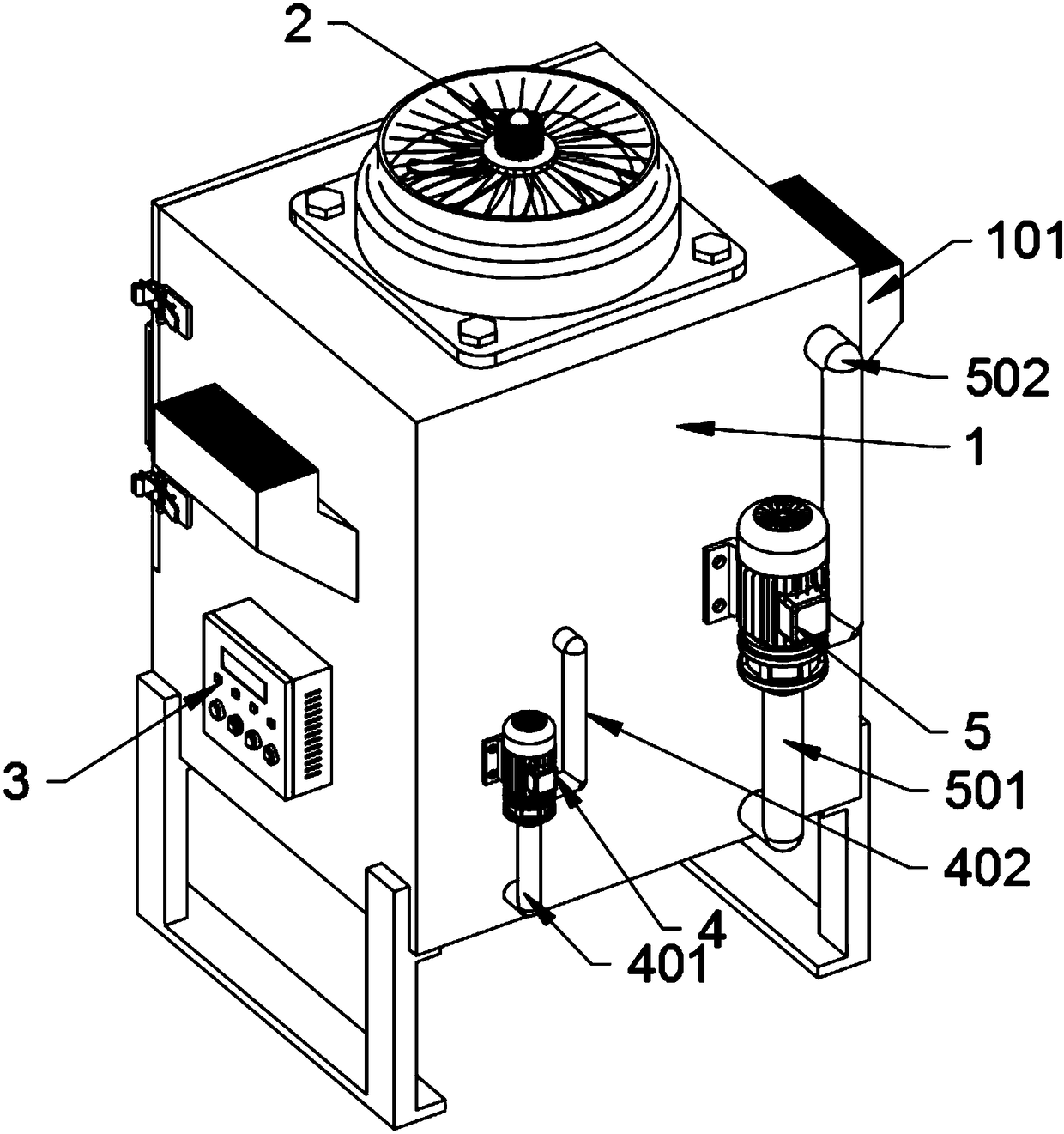

[0037] as attached figure 1 to attach Figure 13 Shown:

[0038] The present invention provides a spray sterilization equipment for injection packaging bottles, which includes a box body 1, a bent air outlet pipe 101, a box door 102, a water tank 103, a drainage ball valve 104, an electric heater 2, a control box 3, Auxiliary water pump 4, auxiliary water pump suction pipe 401, auxiliary water pump spray pipe 402, main water pump 5, main water pump suction pipe 501, main water pump outlet pipe 502, horizontal water guide pipe 6, nozzle 601, cleaning tank 7, cleaning tank drain pipe 701, solenoid valve 702, track rod 8, packaging bottle bracket 9, sliding groove 10, baffle plate 11, locking bolt 1101, arc-shaped water guide block 1102, packaging bottle 12, packaging bottle insertion rack 13 and ejector rod 131 The box body 1 is arranged in a square shape as a whole, and a baffle plate is welded at the bottom position of the front opening. This baffle plate seals the bottom sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com