Freezing mesh belt

A technology of mesh belt and connecting rod, applied in the field of mesh belt, can solve the problems of loud noise and many friction points of the frozen mesh belt, and achieve the effect of reducing noise, compact structure and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

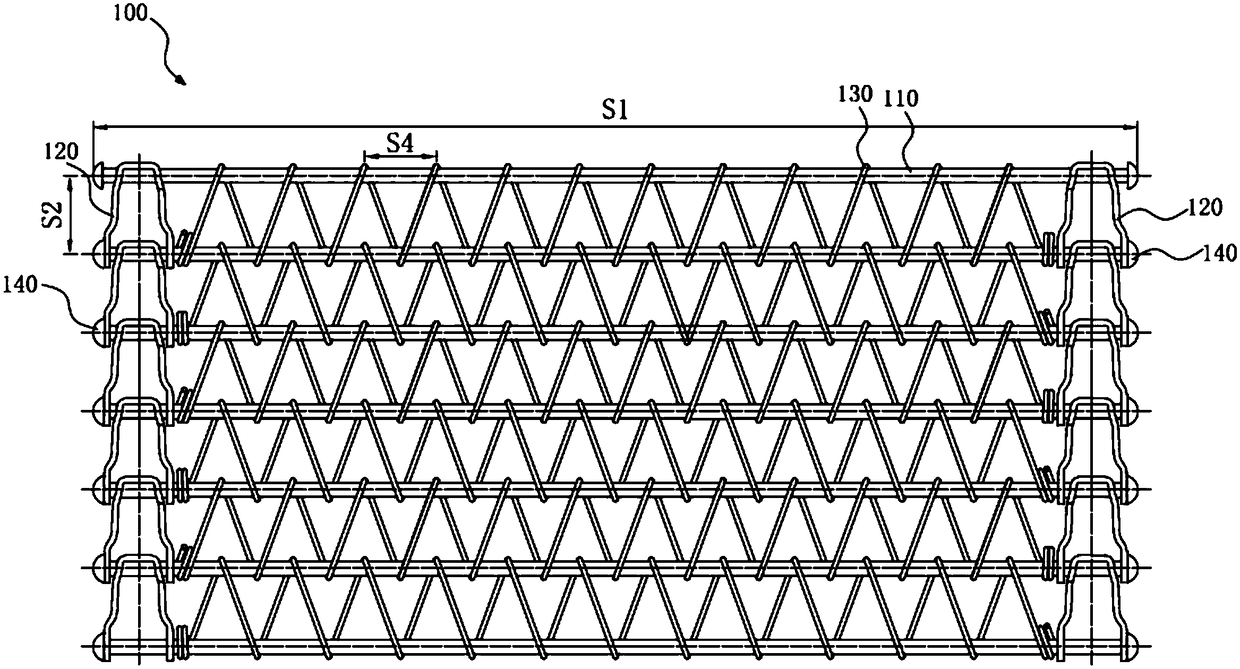

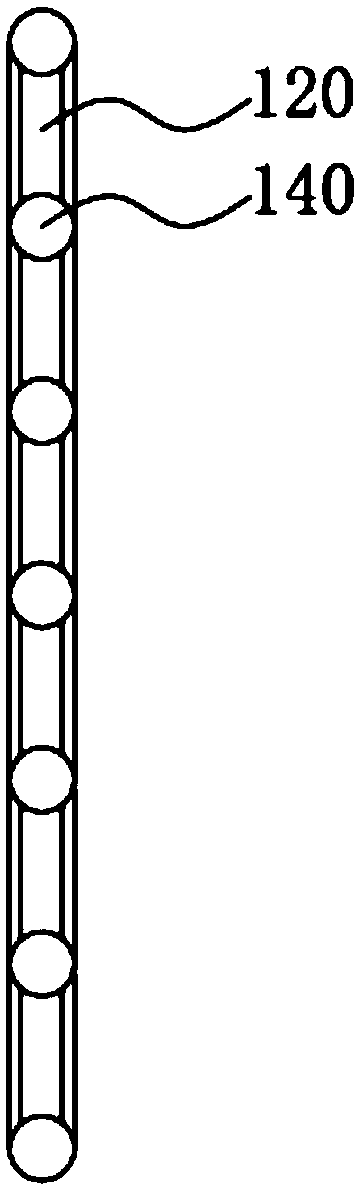

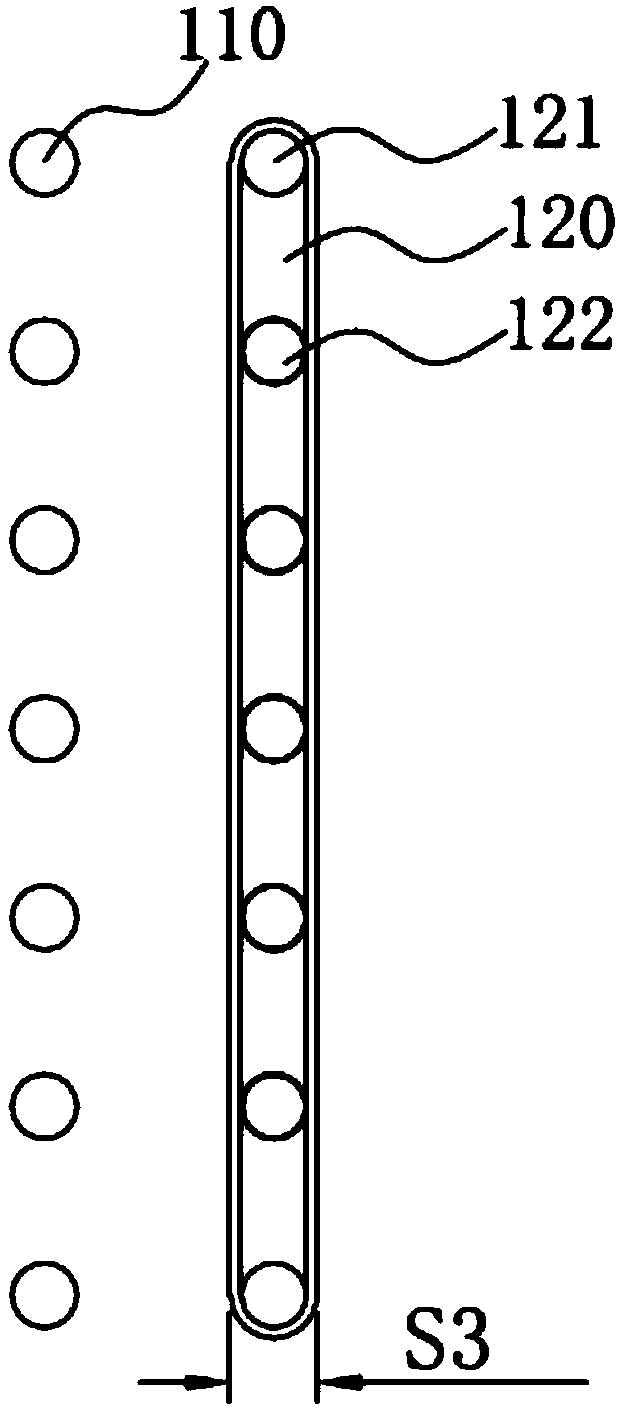

[0024] refer to Figure 1 to Figure 3 , figure 1 A schematic diagram showing the structure of the frozen mesh belt of the present invention, figure 2 Draw a schematic side view of the frozen mesh belt of the present invention, image 3 A side view exploded schematic diagram of the frozen mesh belt of the present invention is shown. In this embodiment, the freezing mesh belt 100 of the present invention includes:

[0025] Several connecting rods 110, the several connecting rods 110 are arranged in parallel with each other;

[0026] Several connecting plates 120, two first serial holes 121 and two second serial holes are arranged on both sides of the several connecting plates 120, wherein one of the several connecting rods 110 passes through the several Two first serial holes 121 of one of the connecting plates 120, and another connecting rod 110 next to the connecting rod 110 passes through the two second serial holes 122 of the connecting plate 120, the two connecting rod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com