Binding treatment device

A processing device and substrate technology, applied in thin material processing, transportation and packaging, object supply, etc., to achieve the effects of convenient operation, long use time, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

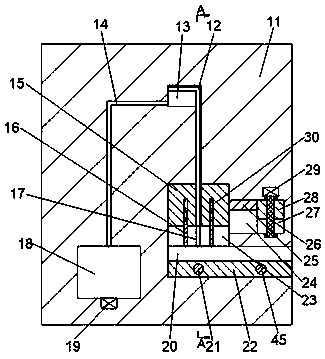

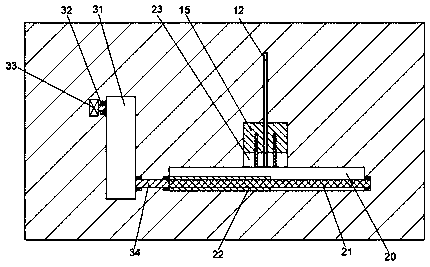

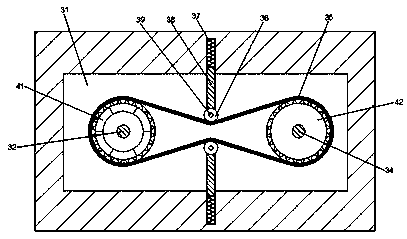

[0019] Combine below Figure 1-5 The present invention will be described in detail.

[0020] Reference Figure 1-5 A binding processing device according to an embodiment of the present invention includes a base 11 in which a working assembly and a pitch adjusting assembly are arranged, the working assembly includes a working cavity 20 arranged in the base 11, the A guide rod 45 is fixedly installed in the front and rear walls of the working chamber 20, and a first threaded rod 21 is rotatably installed in the front and rear walls of the working chamber 20 through a bearing. The guide rod 45 and the first threaded rod 21 The upper thread is fitted with a moving platform 22 that can slide back and forth in the working cavity 20. The upper end wall of the working cavity 20 is connected with a cutter cavity 23, and the cutter cavity 23 is slidably fitted up and down. There is a tool block 15 which is provided with a through groove which penetrates up and down, and a pipe 12 extendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com