A glass molding device and its molding process with tin liquid and vacuum pumping

A vacuuming device and vacuuming technology, applied in glass pressing, glass forming, glass manufacturing equipment, etc., can solve problems such as warping, cracks, and uneven distribution of residual stress in forming components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

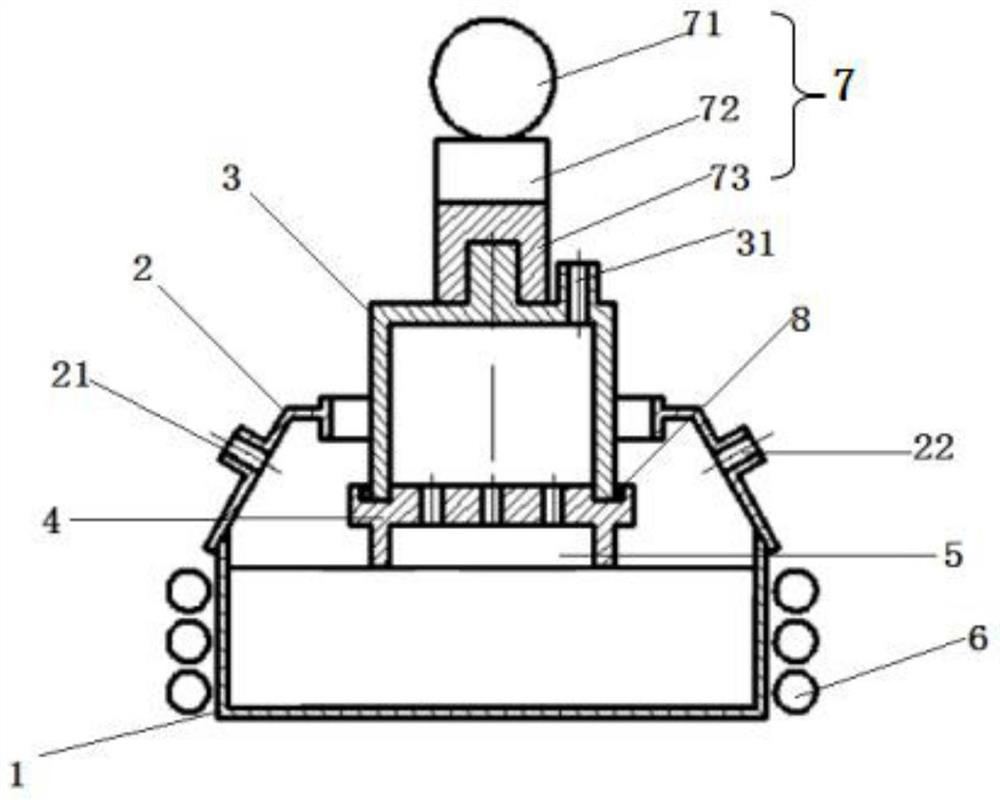

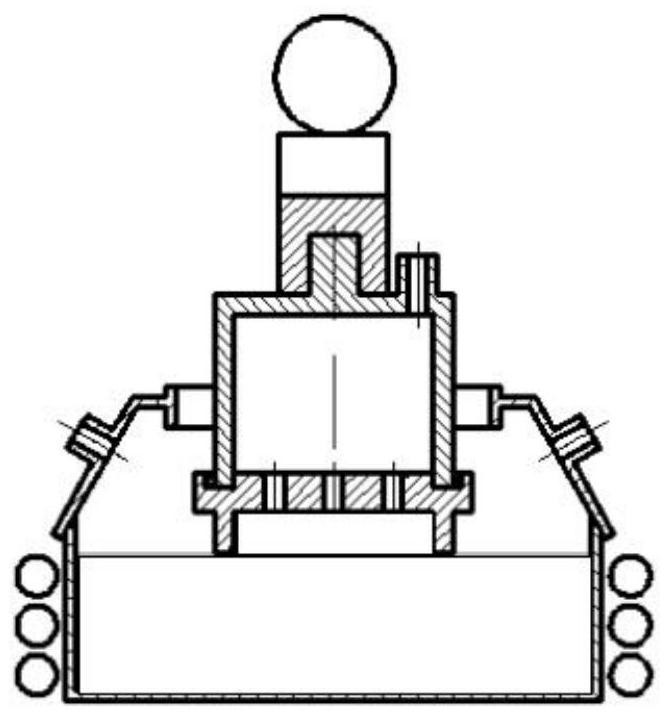

[0044] Refer to attached figure 1 , attached Figure 2a -2d and attached Figure 4 , this embodiment discloses a glass molding device with tin liquid and vacuum pumping, including:

[0045] The liquid tin container 1 is filled with liquid tin.

[0046] Cover 2, cover 2 is arranged on the open end of tin liquid container 1, and encloses molding space with tin liquid container 1; Offers on the cover 2 the nitrogen inlet hole 21 that is used to pass into nitrogen and is used for discharging described Oxygen exhaust holes 22 in the molding space; the center of the cover 2 is provided with a circular through hole for the sleeve 3 to pass through, and the diameter of the circular through hole is not smaller than the maximum diameter of the mold 4 .

[0047] Sleeve 3, one end of the sleeve 3 is closed, one end is open, and its open end is set through the top of the cover 2 towards the liquid surface of the tin liquid, and is slidably connected with the cover 2; the closed end of t...

Embodiment 2

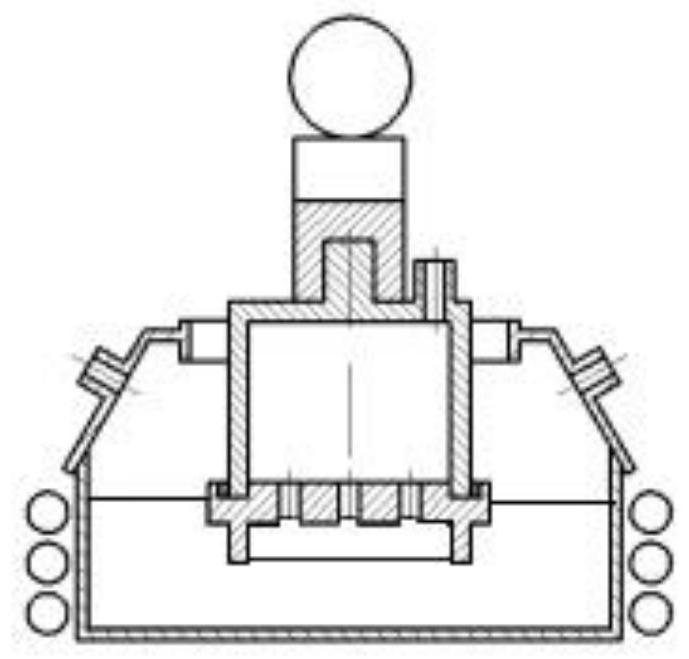

[0063] Refer to attached figure 1 , attached Figure 3a -3d and attached Figure 4 , this embodiment takes the manufacture of micro-columnar glass arrays as an example, the device used is the same as that of embodiment 1, in the specific preparation process, except that the molding process of S3 is different from that of embodiment 1, the rest of the steps are the same as that of embodiment 1.

[0064] Specifically, the specific process of S3 molding in this embodiment is:

[0065] Heat the viscosity of glass 5 to 10 6 ~10 8 After dPa·s, start the sleeve drive device 7, the drive sleeve 3 continues to move towards the bottom wall direction of the tin liquid container 1, until the mold 4 and the glass 5 move below the tin liquid level, start the vacuum device to further reduce The inner pressure of the lower sleeve increases the pressure difference between the sleeve 3 and the molding space. After standing still for 1 min, the glass 5 is filled into the mold 4 to form a mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com