Device and method for fast enrichment multiplication and purifying culture of anaerobic ammonium oxidation bacteria

An anammox bacteria, enrichment technology, applied in the field of environmental biology, can solve the problem of the number and purity of anammox bacteria, the inability to obtain anammox activated sludge, and the low content of anammox bacteria, etc. problems, to achieve the effect of increasing interception and full utilization of nutrient solution, rapid enrichment and proliferation and purification of anaerobic oxidation bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

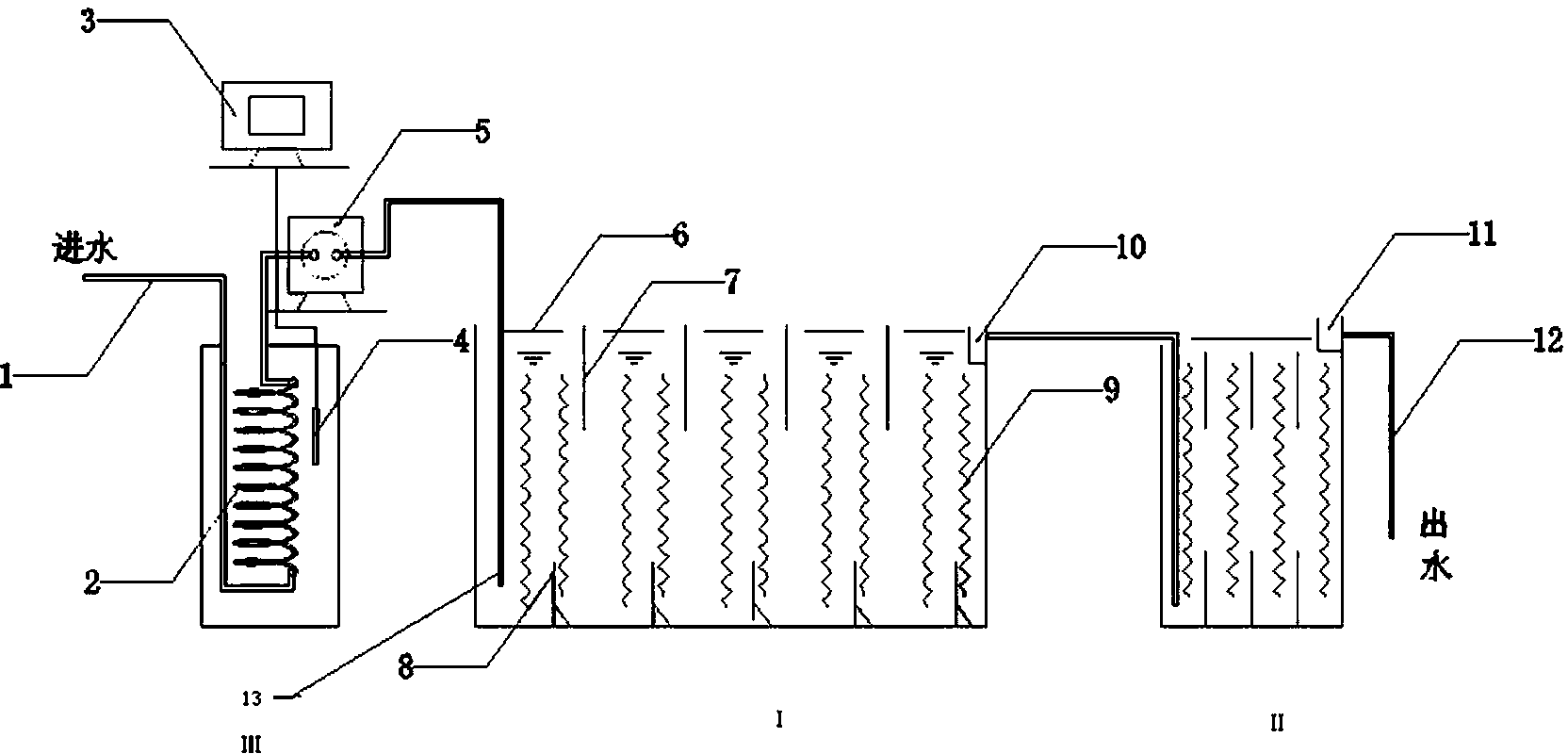

[0032] refer to figure 1 , a device for rapidly enriching, proliferating and purifying anammox bacteria is composed of three parts connected in sequence: an influent preheating system, a tank-type biological reaction tank and a filter tank.

[0033] The water inlet preheating system consists of a preheating pool body, water inlet pipe 1, a heating mechanism 2, a temperature measuring mechanism 4, a temperature control mechanism 3 and a peristaltic pump 5. The heating mechanism 2 and the temperature measuring mechanism 4 are arranged in the preheating pool body. The peristaltic pump 5 communicates with the helical heating tube of the heating mechanism 2 and the trough bioreaction tank through a pipeline 12 .

[0034] The trough bioreactor consists of a pool body and more than two sets of cloth-like hanging fiber-type packing 8 arranged in the pool body and a foam-type covering plate 6 arranged on the surface of the pool body. Between the cloth-like hanging fiber-type packing 8 ...

Embodiment 2

[0039] Pour the preheated culture solution into a volume of 10m 3 In the reaction tank, place a prefabricated baffle plate made of fiber filler in the tank, add 100L of pond bottom mud as the initial source of anammox bacteria and start the internal circulation agitator, connect the culture solution inlet system, put The prepared culture solution is pumped into the reaction tank at a flow rate of 3L / min, and it is started once every 6 hours every day, and the inner circulation agitator is started every 20 minutes to stir the influent and the sludge deposited at the bottom to make them fully mix, and cultivate for 60 -70 days, when the fibrous filler is covered with reddish-brown attachments, take out the fibrous filler, elute the attachments on it, settle still, skim the supernatant, and leave the reddish-brown slurry at the bottom, namely It is high-purity (anammox bacteria content ≥ 80%) anammox denitrification activated sludge. The amount of anaerobic ammonium oxidation sl...

Embodiment 3

[0041] Pour the preheated culture solution into a volume of 10m 3 In the reaction tank, a prefabricated baffle plate composed of fiber filler is placed in the tank, and 200L of granular sludge taken from anaerobic treatment is added as the initial source of anammox bacteria, and the internal circulation agitator is started, and the culture solution is connected to the water System, pump the prepared culture solution into the bottom of one end of the reaction tank with a peristaltic pump at a flow rate of 5L / min, start it once every 4 hours, and start the internal circulation agitator every 10 minutes to clean the influent and bottom sediment sludge Mix well and culture for 60-80 days. When the fibrous filler is covered with reddish-brown attachments, take out the fibrous filler, elute the attachments on it, settle still, skim off the supernatant, and leave the reddish-brown color at the bottom. Slurry is high-purity (anammox bacteria content ≥ 80%) anammox denitrification acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com