Integrated sewage treatment bench-scale device and process method

A sewage treatment and container main body technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, anaerobic digestion treatment, etc., can solve the problems of weak sedimentation performance, sludge bulking, high operating cost, etc., to achieve The effect of reducing impact, increasing denitrification rate, and enhancing phosphorus removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

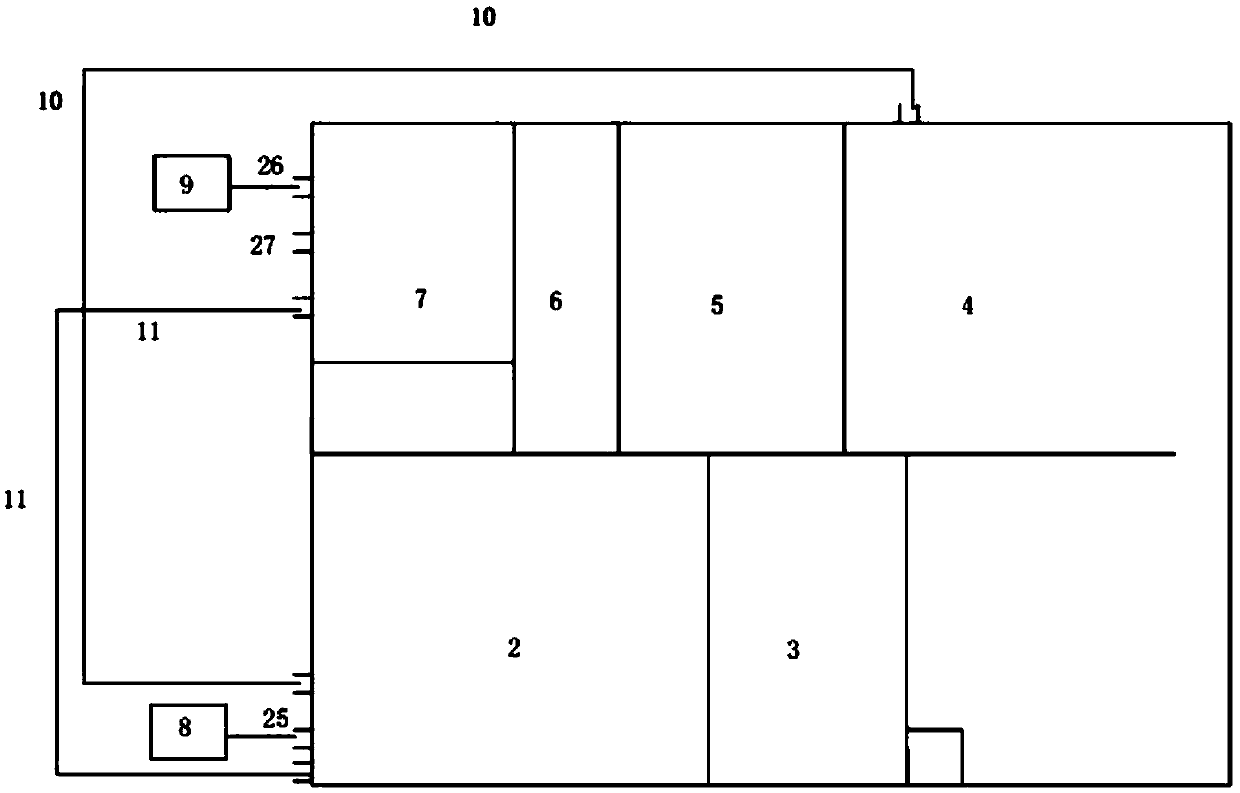

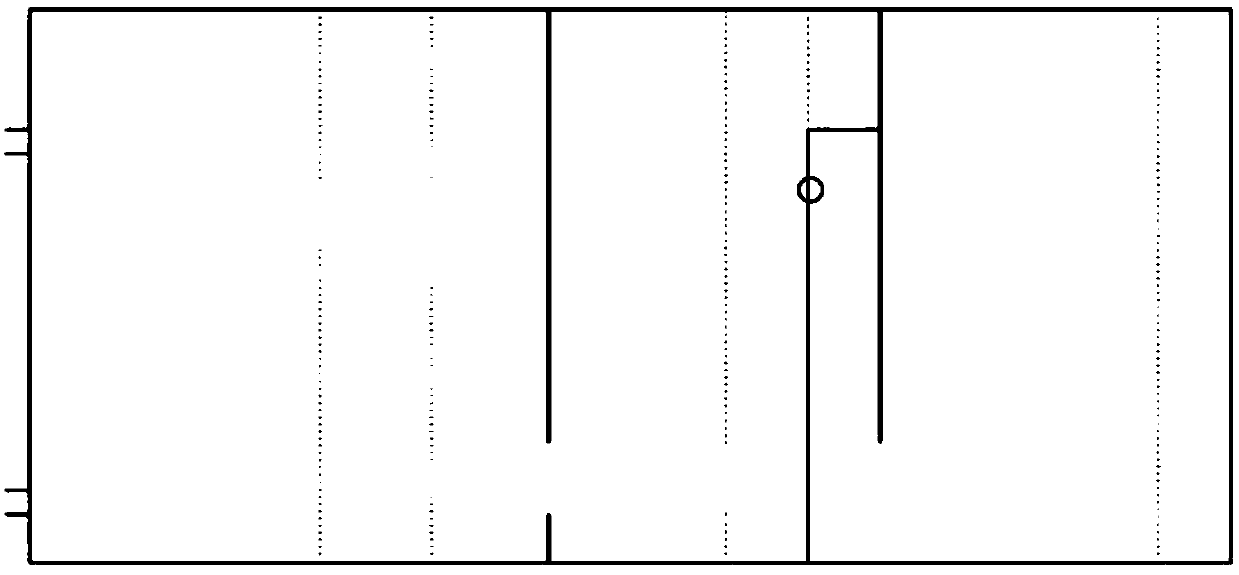

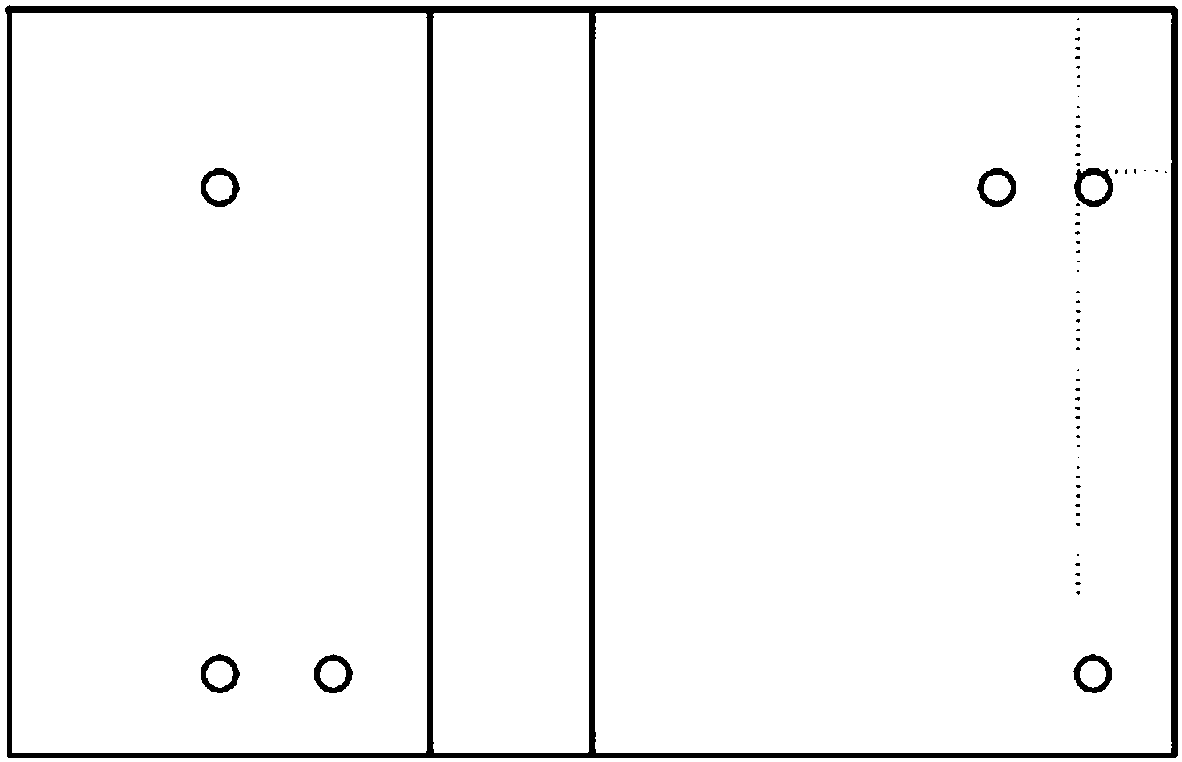

[0035] as attached figure 1 Shown in: 1-integrated container body, 2-first anoxic zone, 3-anaerobic zone, 4-first aerobic zone, 5-second anoxic zone, 6-second aerobic zone, 7 -Membrane area, 8-water storage tank, 9-sludge storage tank, 10-mixed liquid return pipe, 11-sludge return pipe, 12-membrane module, 13-hydraulic agitator, 14-valve, 15-air flow meter, 16-peristaltic pump, 17-self-priming pump, 18-air compressor, 19-cleaning pump, 20-pressure gauge, 21-relay, 22-aeration sand head, 23-aeration pipe, 24-baffle, 25 - water inlet, 26- mud discharge port, 27- water outlet, 28- bracket;

[0036] An integrated sewage treatment small test device, characterized in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com