Enhanced wastewater phosphorus removal method

A technology for sewage and sludge, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of difficulty in recycling phosphorus resources, poor phosphorus removal effect, etc., and achieve increased links and treatment costs. , save costs, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

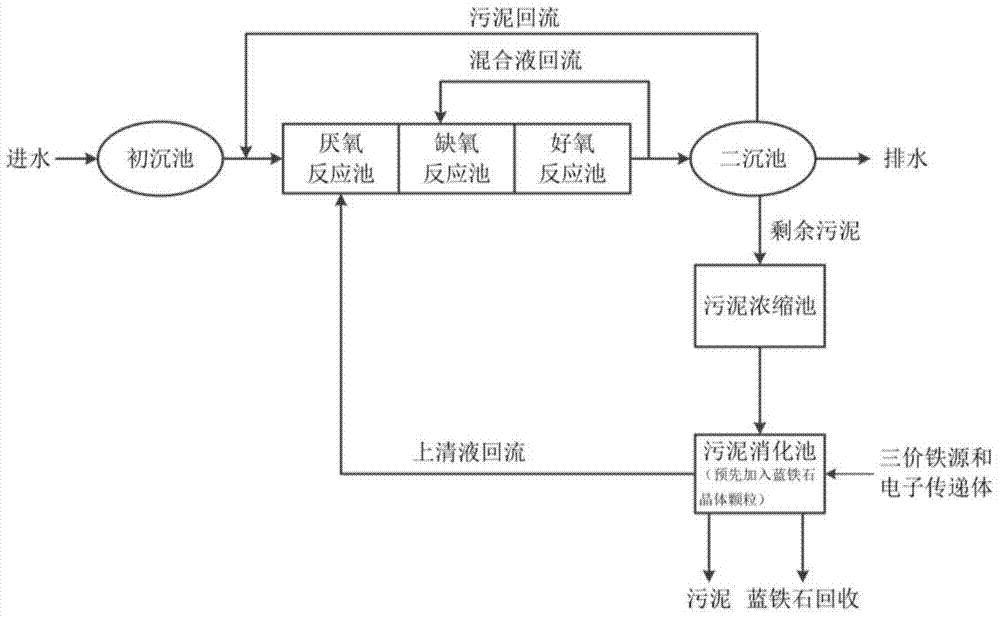

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Take A 2 / O is 5L of activated sludge in the secondary sedimentation tank of a sewage treatment plant that is the main treatment process. The sludge is placed for 1 day by gravity concentration, and the total phosphorus concentration is determined to be 700mg / L. Take 1L of this concentrated sludge and place it in an anaerobic reactor, and add 50 g of blue-ironite crystals at the bottom of the reactor, with an average particle size of 4 mm. Set the temperature of anaerobic digestion to 35°C, the rising velocity of sludge to 0.05m / s, add 42.4mmol of amorphous FeOOH, react for 21 days, and monitor the changes of soluble phosphate in the sludge digestion system. The results showed that compared with the final dissolved phosphorus concentration of 240mg / L in the control experiment, the final phosphorus concentration of the anaerobic digestion system with FeOOH was 80mg / L, and the phosphorus concentration was reduced by 67%.

Embodiment 2

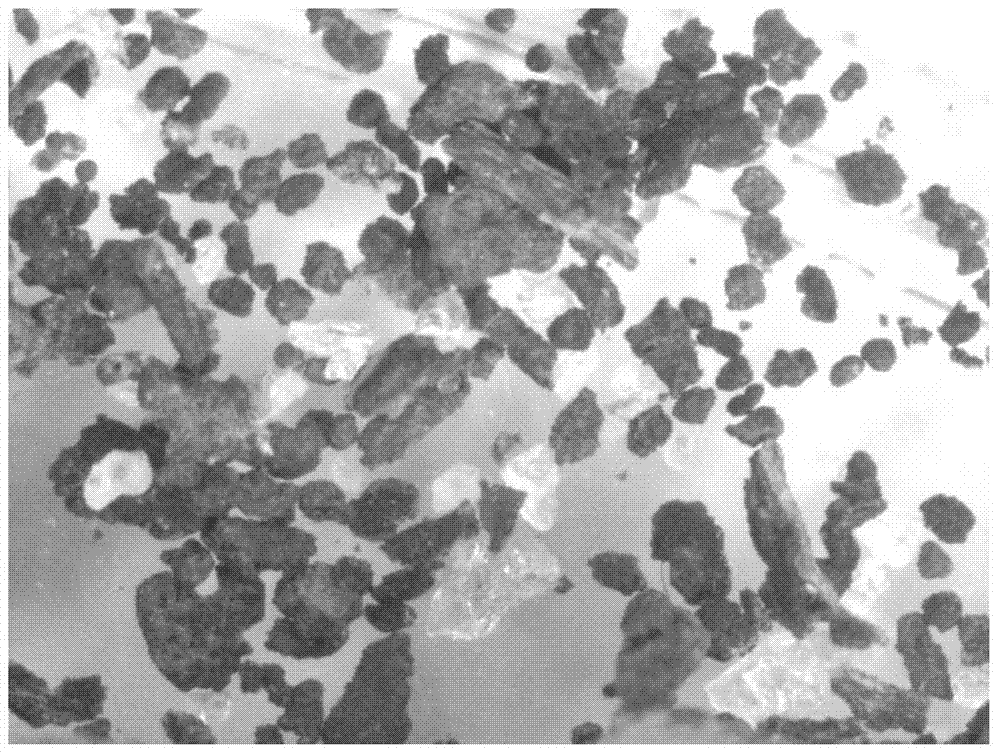

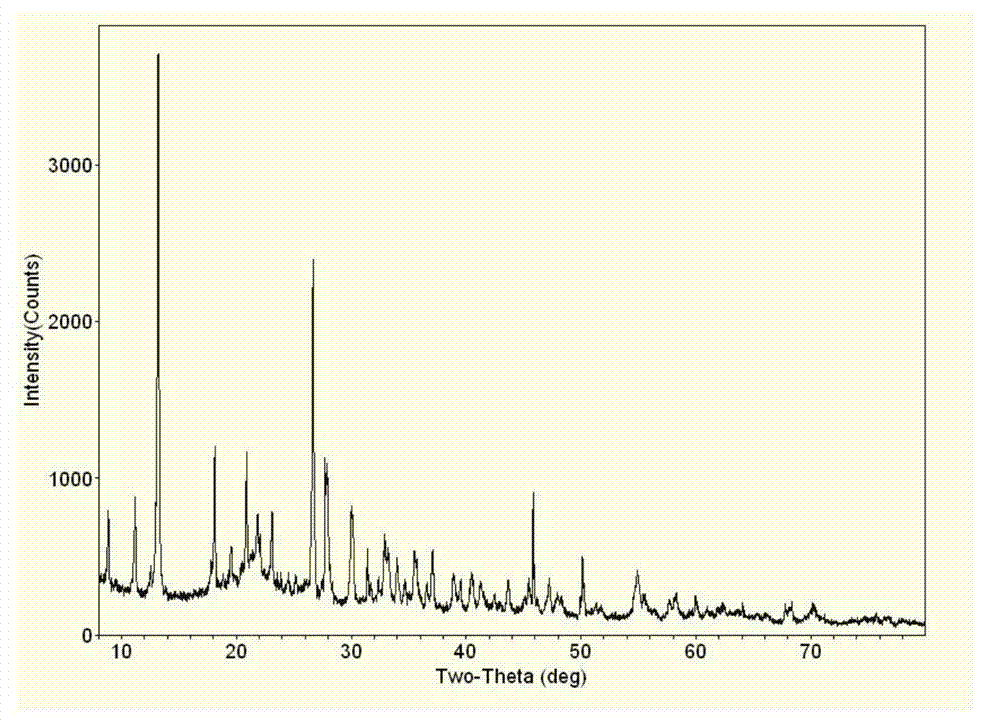

[0049] A 2 / O is the activated sludge in the secondary sedimentation tank of the sewage treatment plant in the main treatment process. After gravity concentration for 1 day, the total phosphorus concentration of the sludge is 610-750mg / L. The concentrated sludge was added to a CSTR reactor with an effective volume of 1L containing 10g blue-ironite seeds (average particle size 3mm) as the experimental material, and amorphous FeOOH was added at the same time according to the Fe / sludge TP molar ratio of 2.0 , set the temperature of anaerobic digestion to 55°C, and the sludge rising velocity to 0.05m / s, and run for 108 days in total. It has been confirmed by testing that after a period of operation, the crystal size of blue-ironite in the mud phase of the digester increases, and no other associated minerals are formed, and the phase is single, such as figure 2 , image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com