Porous nitrogen and phosphorus removal filler for artificial wetland and preparation method of porous nitrogen and phosphorus removal filler

A technology for denitrification and phosphorus removal, constructed wetlands, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. Small load and other problems, to achieve the effect of low production cost, increased specific surface area, and small specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

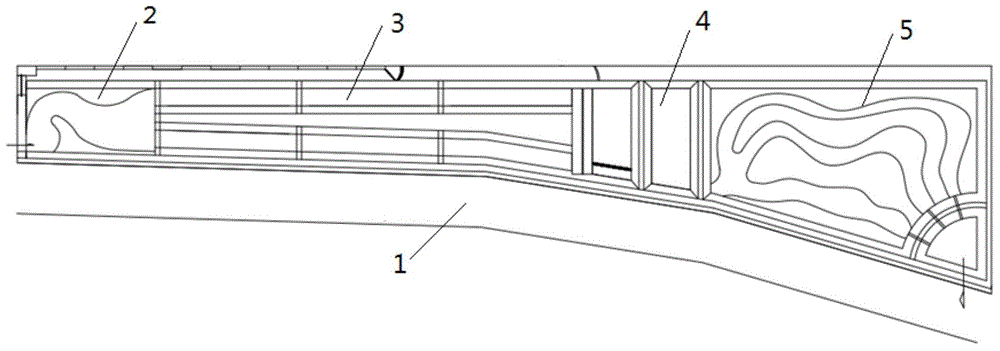

Image

Examples

Embodiment 1

[0031] This example relates to a porous nitrogen and phosphorus removal filler used in constructed wetlands, which uses sand, Yunnan red soil, cement, quicklime, gypsum, aluminum powder, water, etc. as the main raw materials, and uses steam pressurization to produce foam Yunnan red soil is immobilized to make porous materials.

[0032] The specific preparation mainly includes the following process steps:

[0033] 1. According to the mass percentage of the total weight of raw materials, mix 20% of sand, 19% of Yunnan red soil, 5% of cement, 10.93% of quicklime, 2% of gypsum, and 43% of water to make a mixed slurry. The measured slurry Put into pouring mixer;

[0034] 2. Make a suspension of 0.07% aluminum powder, stir for about 30s, and put the stirred suspension into the pouring mixer about 1 minute before pouring;

[0035] 3. The temperature of the slurry should reach 35-38°C before pouring. If the temperature is not enough, it can be heated by steam;

[0036] 4. The pouri...

Embodiment 2

[0044] This example relates to a porous nitrogen and phosphorus removal filler used in constructed wetlands, which uses sand, Yunnan red soil, cement, quicklime, gypsum, aluminum powder, water, etc. as the main raw materials, and uses steam pressurization to produce foam Yunnan red soil is immobilized to make porous materials.

[0045] The specific preparation mainly includes the following process steps:

[0046] 1. According to the mass percentage of the total weight of raw materials, mix 23% of sand, 15% of Yunnan red soil, 7% of cement, 12% of quicklime, 1.6% of gypsum, and 41.35% of water to make a mixed slurry. The measured slurry Put into pouring mixer;

[0047] 2. Make a suspension of 0.05% aluminum powder, stir for about 30s, and put the stirred suspension into the pouring mixer about 2 minutes before pouring;

[0048] 3. The temperature of the slurry should reach 35-38°C before pouring. If the temperature is not enough, it can be heated by steam;

[0049] 4. The po...

Embodiment 3

[0056] This example relates to a porous nitrogen and phosphorus removal filler used in constructed wetlands, which uses sand, Yunnan red soil, cement, quicklime, gypsum, aluminum powder, water, etc. as the main raw materials, and uses steam pressurization to produce foam Yunnan red soil is immobilized to make porous materials.

[0057] The specific preparation mainly includes the following process steps:

[0058]1. According to the mass percentage of the total weight of raw materials, mix 25% of sand, 20% of Yunnan red soil, 6% of cement, 9% of quicklime, 1.94% of gypsum, and 38% of water to make a mixed slurry. The measured slurry Put into pouring mixer;

[0059] 2. Make a suspension of 0.06% aluminum powder, stir for about 30s, and put the stirred suspension into the pouring mixer about 1 minute before pouring;

[0060] 3. The temperature of the slurry should reach 35-38°C before pouring. If the temperature is not enough, it can be heated by steam;

[0061] 4. The pouring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com