A kind of aao sewage treatment system that meets the standard of four types of surface water and its process

A sewage treatment system and surface water technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve unfavorable promotion and application, high cost of sewage treatment, water quality Large fluctuations and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

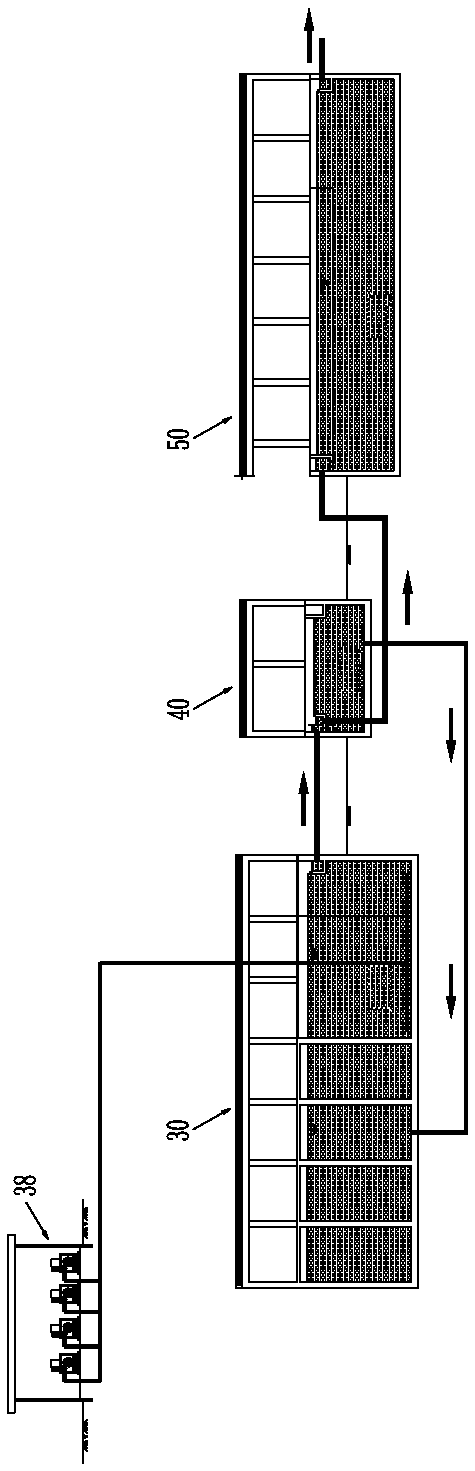

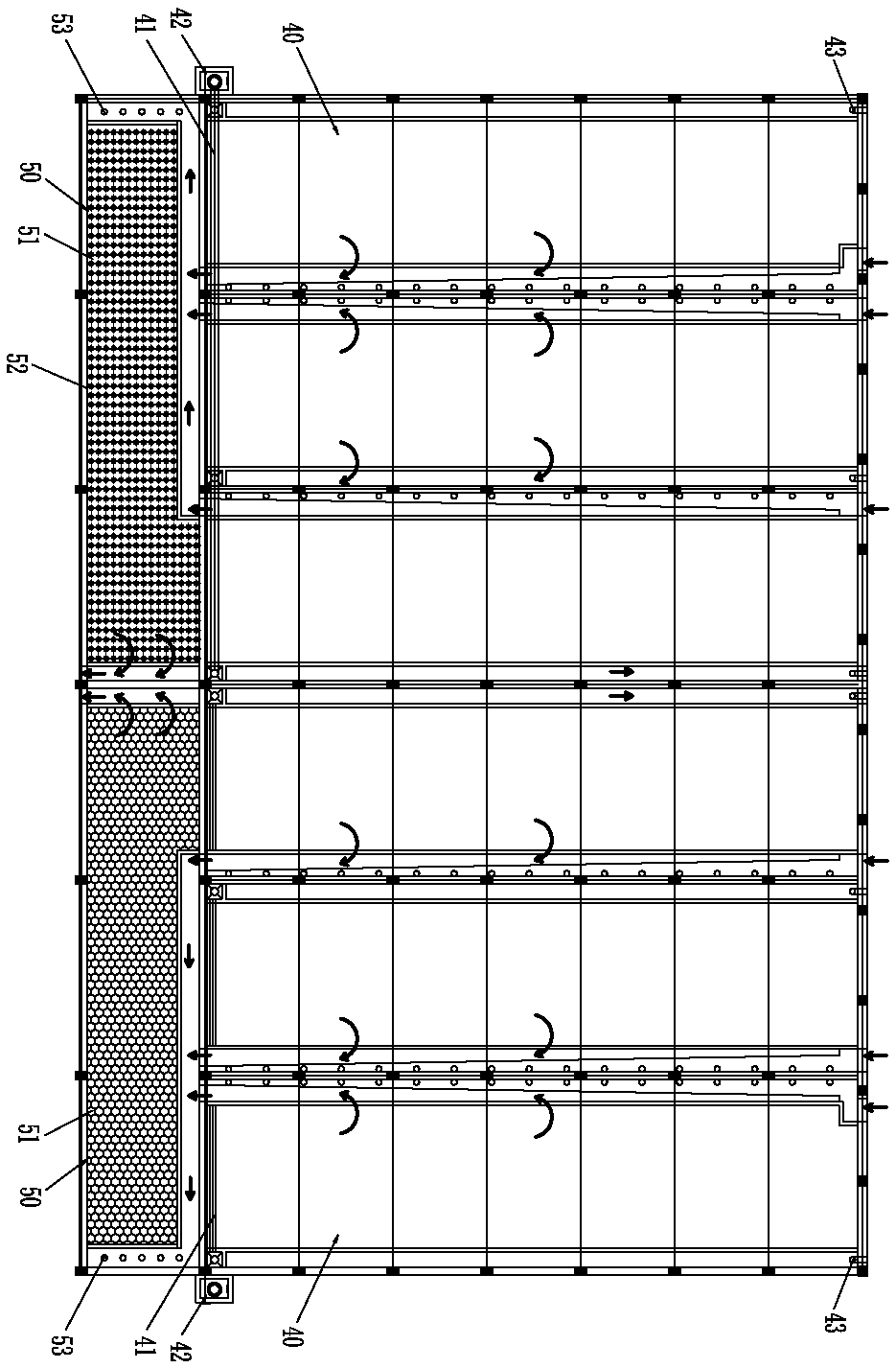

[0038] Please refer to Figure 1 to Figure 3 As shown, it has shown the concrete structure of the embodiment of the present invention, and here, take the AO-KEDA process system that the applicant studies meticulously as an example; Into and out of the rectangular secondary sedimentation tank 40 and the biological contact oxidation tank 50 .

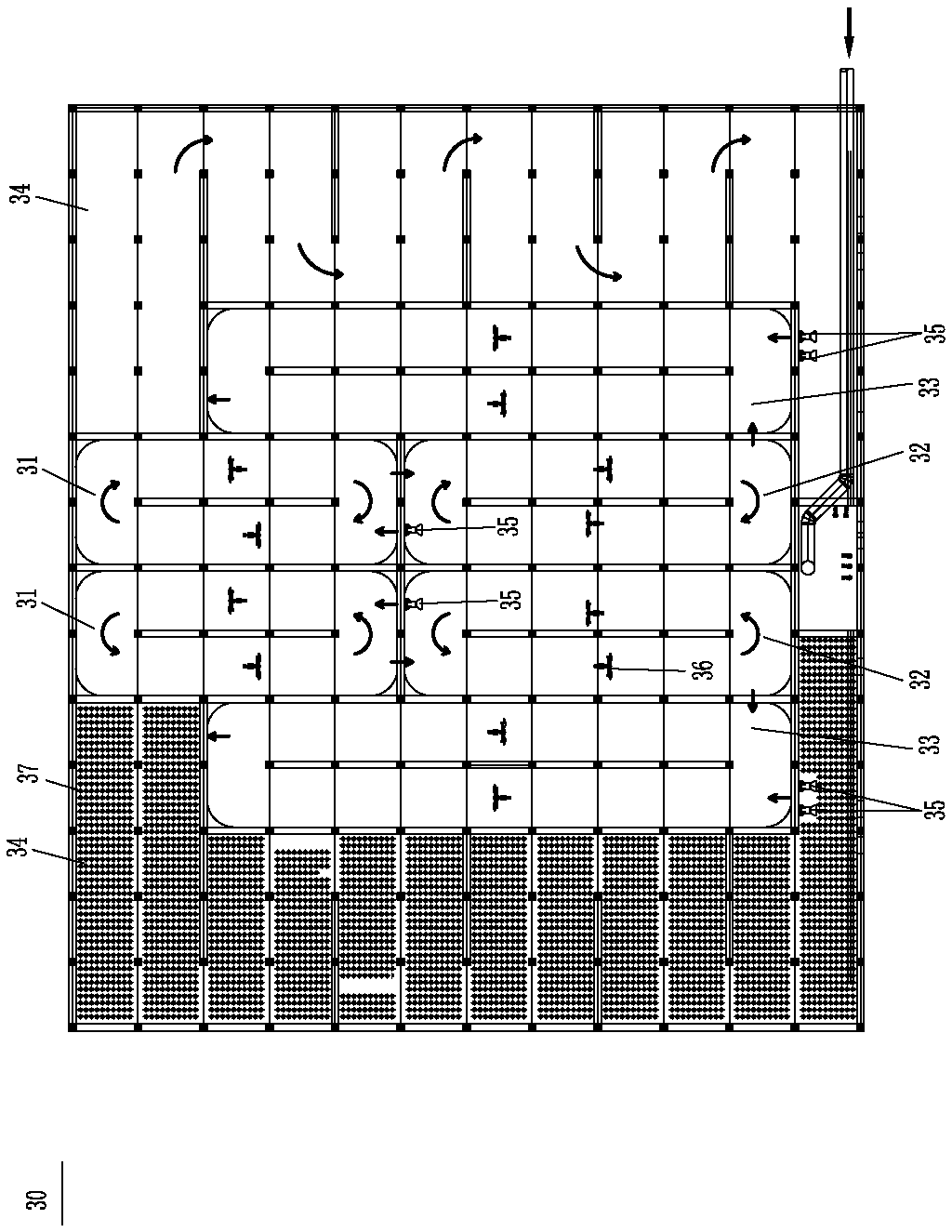

[0039]The AAO biochemical pool 30 includes an anaerobic pool 31, a first anoxic pool 32, a second anoxic pool 33 and an aerobic pool 34; the AAO biochemical pool 30 is connected with an air suspension centrifugal blower (a blower room 38 can be specially set up) ; The aerobic pool 34 is provided with a microporous aerator; the sewage to be treated enters the water inlet of the anaerobic pool 31, and the water outlet of the anaerobic pool 31 is connected to the water inlet of the first anoxic pool 32, and the first The water outlet end of anoxic pond 32 is connected with the water inlet end of the second anoxic pond 33, and the water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com