Low-volatility UV curing optical structural adhesive and preparation method thereof

A low-volatility, optical structure technology, applied in adhesives, non-polymer organic compound adhesives, non-polymer adhesive additives, etc., can solve the problem of reducing the content of active diluents, low volatility of optical structural adhesive materials, etc. problem, achieve the effect of reducing the residue of small molecular substances, avoiding the difference in curing degree, and reducing the proportion of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

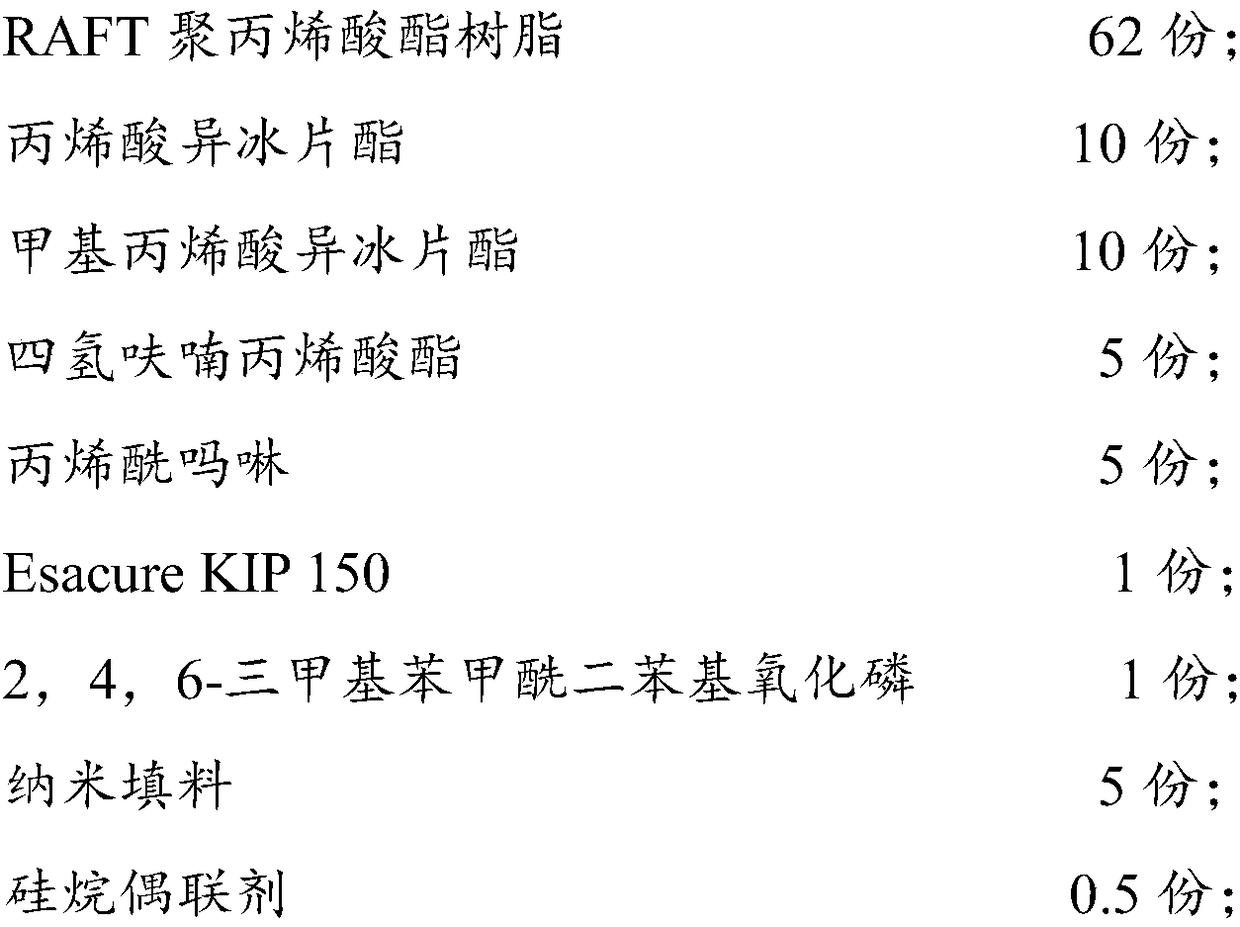

[0039] A low-volatility UV-curable optical structural adhesive, comprising the following components calculated by mass percentage:

[0040]

[0041]

[0042] The RAFT polyacrylate resin described in this implementation is prepared by the following method:

[0043] (1) Add 2g thermal initiator (AIBN), 0.3gRAFT reagent and 500mL xylene into a four-necked flask with stirrer, temperature control device and nitrogen protection device;

[0044] (2) Warm up to 90°C, gradually add 80g of isooctyl acrylate and 20g of 2-phenoxyethyl acrylate dropwise, control the dropping speed, the monomer dropping time is 4 hours, and then continue to react for 3h;

[0045] (3) After the polymerization reaction is complete, 0.1 g of N,N dimethyldipropyltriamine is added to decolorize the resin, and finally the solvent is evaporated to obtain a colorless and transparent viscous resin RAFT polyacrylate resin.

[0046] Get 2g of the prepared colorless and transparent viscous resin RAFT polyacrylat...

Embodiment 2

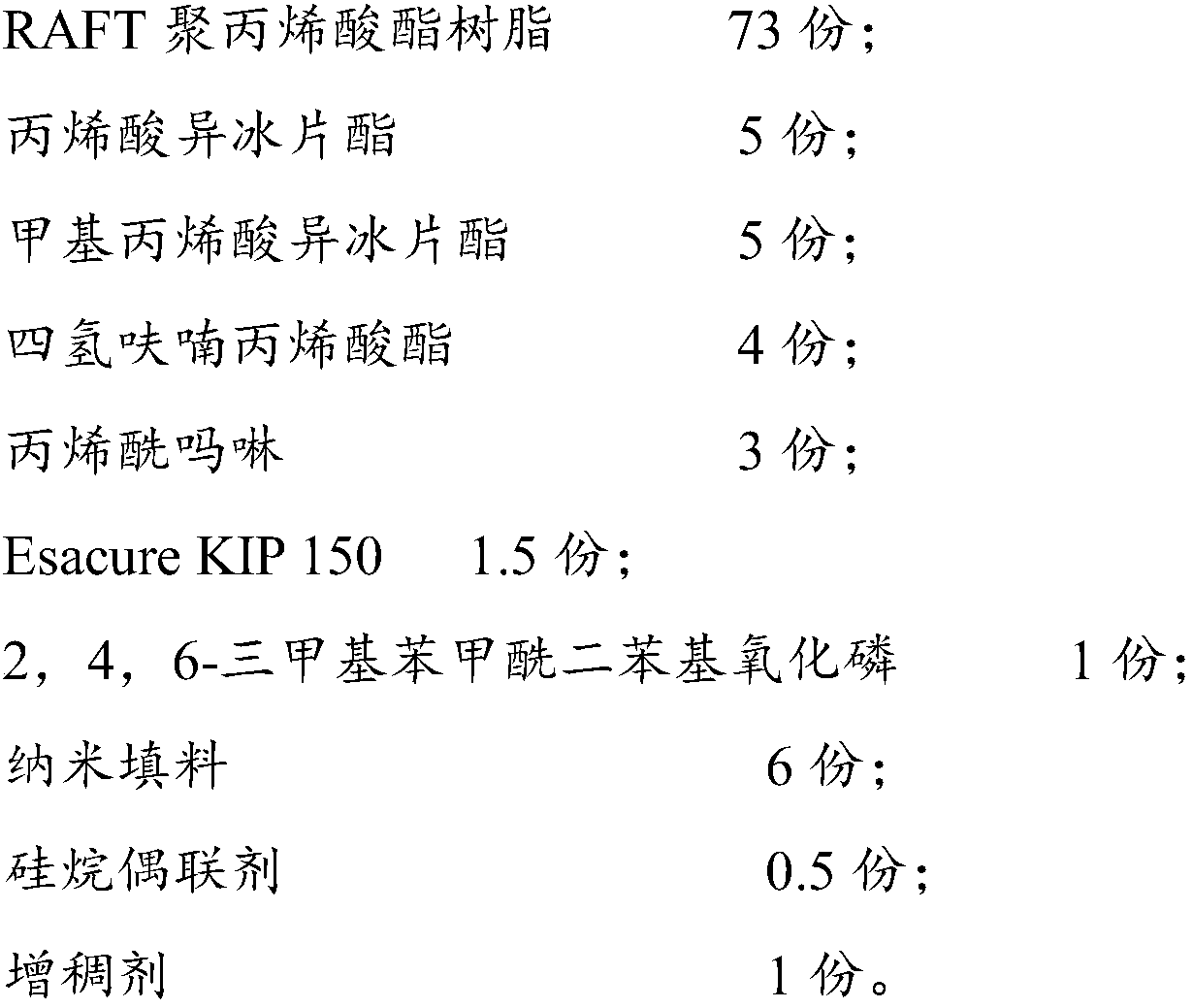

[0053] A low-volatility UV-curable optical structural adhesive, its composition and preparation method are similar to Example 1, the difference is that the RAFT polyacrylate resin used in Example 2 is different from Example 1, and the RAFT polyacrylate resin used in Example 2 The synthesis process of RAFT polyacrylate resin is as follows:

[0054] (1) Add 2g thermal initiator (AIBN), 0.3gRAFT reagent and 500mL xylene into a four-necked flask with stirrer, temperature control device and nitrogen protection device;

[0055] (2) Heat up to 90°C, gradually add 60g of decyl acrylate and 20g of piperidine ethyl acrylate dropwise, control the rate of addition, the monomer addition time is 4 hours, and then continue the reaction for 3h;

[0056] (3) After the polymerization reaction is complete, 0.1 g of N,N dimethyldipropyltriamine is added to decolorize the resin, and finally the solvent is evaporated to obtain a colorless and transparent viscous resin RAFT polyacrylate resin.

[0...

Embodiment 3

[0059] A low-volatility UV-curable optical structural adhesive, its composition and preparation method are similar to Example 1, the difference is that the RAFT polyacrylate resin used in Example 3 is different from Example 1, and the RAFT polyacrylate resin used in Example 3 The synthesis process of RAFT polyacrylate resin is as follows:

[0060] (1) Add 2g thermal initiator (AIBN), 0.2gRAFT reagent and 500mL xylene into a four-necked flask with stirrer, temperature control device and nitrogen protection device;

[0061] (2) Warm up to 90°C, gradually add 90g of isooctyl acrylate and 20g of 2-phenoxyethyl acrylate dropwise, control the dropping rate, the monomer dropping time is 4 hours, and then continue to react for 3h;

[0062] (3) After the polymerization reaction is complete, 0.1 g of N,N dimethyldipropyltriamine is added to decolorize the resin, and finally the solvent is evaporated to obtain a colorless and transparent viscous resin RAFT polyacrylate resin.

[0063] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com