Gate Drive Sealing Mechanism

A technology of sealing mechanism and gate, which is applied in sea area engineering, construction, barrage/weir, etc. It can solve the problems of poor sealing degree, poor fixing firmness of gate, easy aging of sealing layer and leakage of water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

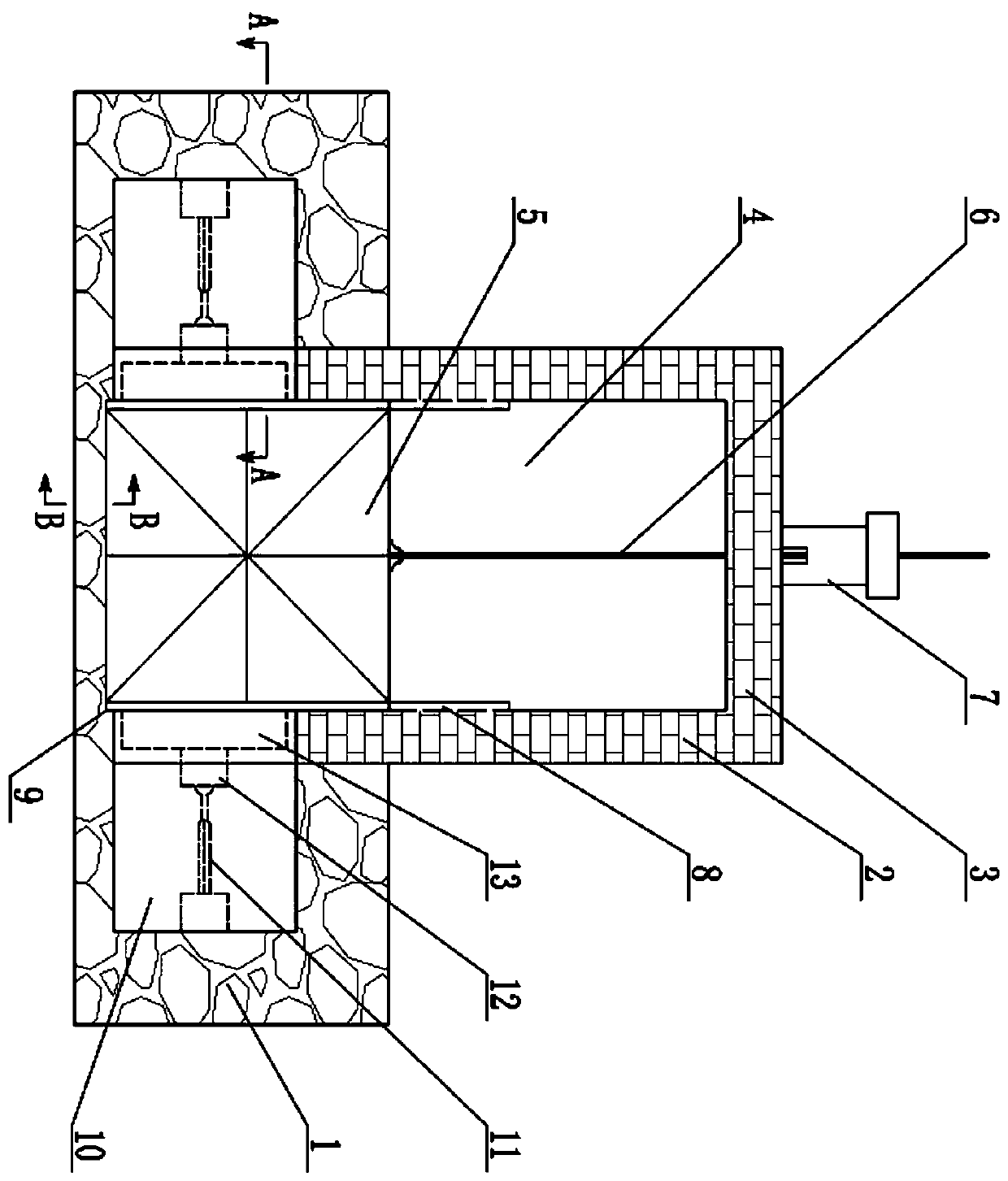

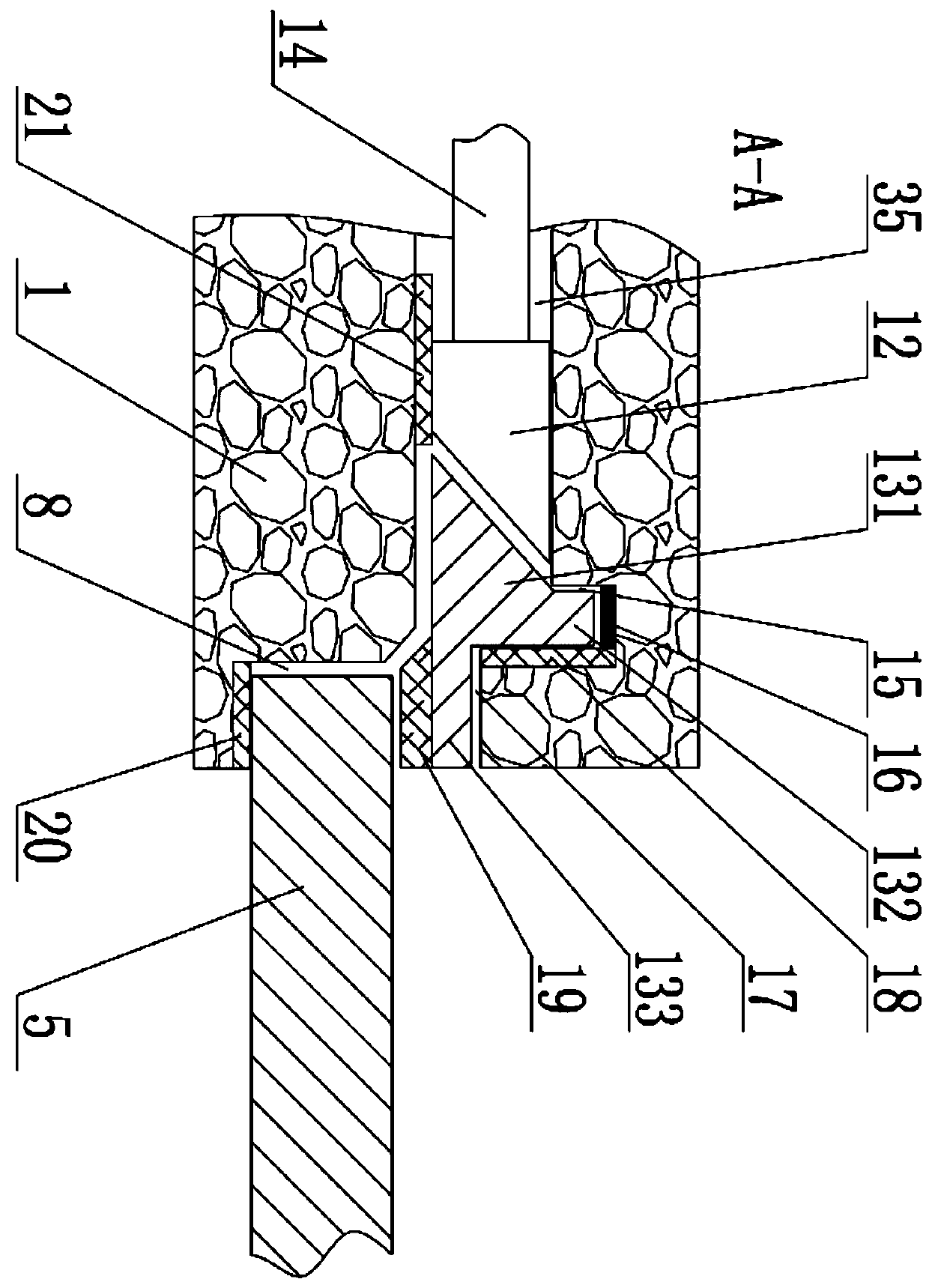

[0018] Embodiment 1: as figure 1 As shown, the foundation 1 is built inward along the side slope of the river, and the middle part of the foundation 1 on both sides forms a water-passing gate. A vertical column 2 is arranged on the upper side of the foundation 1 on both sides and a beam 3 is arranged on the upper end of the column 2 on both sides. , constituting the bracket for the hoisting of the gate 5 and the hoisting section 4, and a hoisting motor 7 is installed in the middle of the upper end of the beam 3.

[0019] The gate 5 is located inside the uprights 2 on both sides, and track grooves 8 are arranged at symmetrical positions on the inner surfaces of the two uprights 2 , and the two sides of the gate 5 are clamped in the track grooves 8 on both sides. A lifting screw 6 is installed in the middle part of the upper end of the gate 5, and the lifting screw 6 is installed in the rotating screw hole at the output end of the lifting motor 7. Here, the lifting motor 7 and ...

Embodiment 2

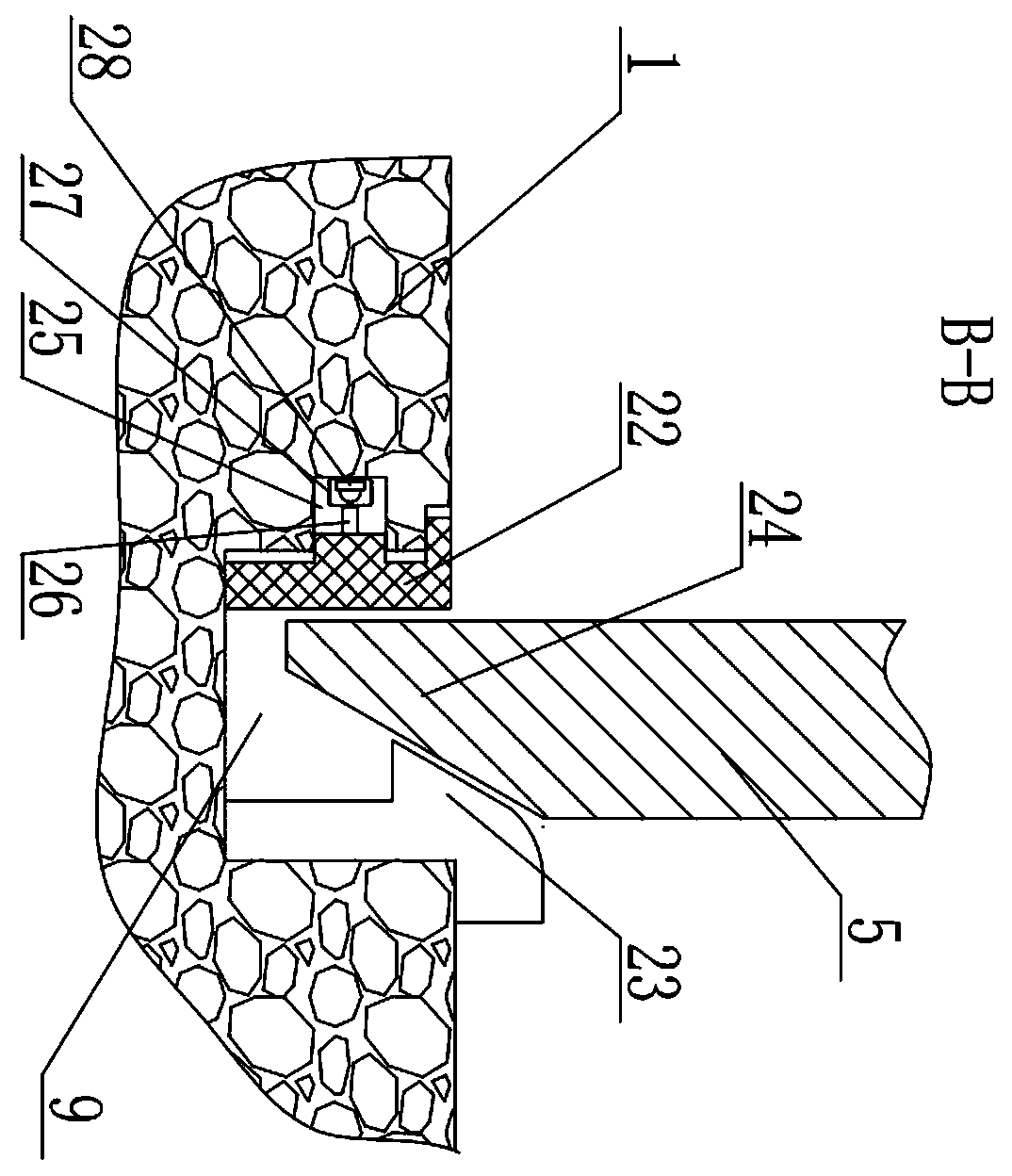

[0025] Embodiment 2: On the basis of Embodiment 1, automatic cooperation with manual control of the hydraulic cylinder 11 and the lifting motor 7 can be realized. Such as Figure 4 As shown, a switch chamber 25 is arranged in the backwater side wall of the bottom tank 9, and a switch seal bag 27 is installed in the switch chamber 25 for sealing the SPDT switch 28, and the SPDT switch 28 is sealed and set in the switch seal bag 27 can be connected with insulated wires without wading.

[0026] The way to drive the SPDT switch 28 is to vertically connect the push rod 26 on the back of the bottom groove extrusion gasket 22, the push rod 26 corresponds to the push knob position of the switch sealing bag 27 and the SPDT switch 28, and the push rod 26 moves Then the SPDT switch 28 switches. The power connection mode of the SPDT switch 28: after the common terminal of the SPDT switch 28 is connected to the coil terminal 1 of the relay, the coil terminal 2 of the relay is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com