Filter screen assembly of extractor hood and extractor hood comprising same

A range hood and filter technology, which is applied in the field of kitchen appliances, can solve the problems of bacterial odor, affecting the performance of the hood, single way of filtering and intercepting grease, etc., and achieves the effects of easy disassembly, reduced emissions, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

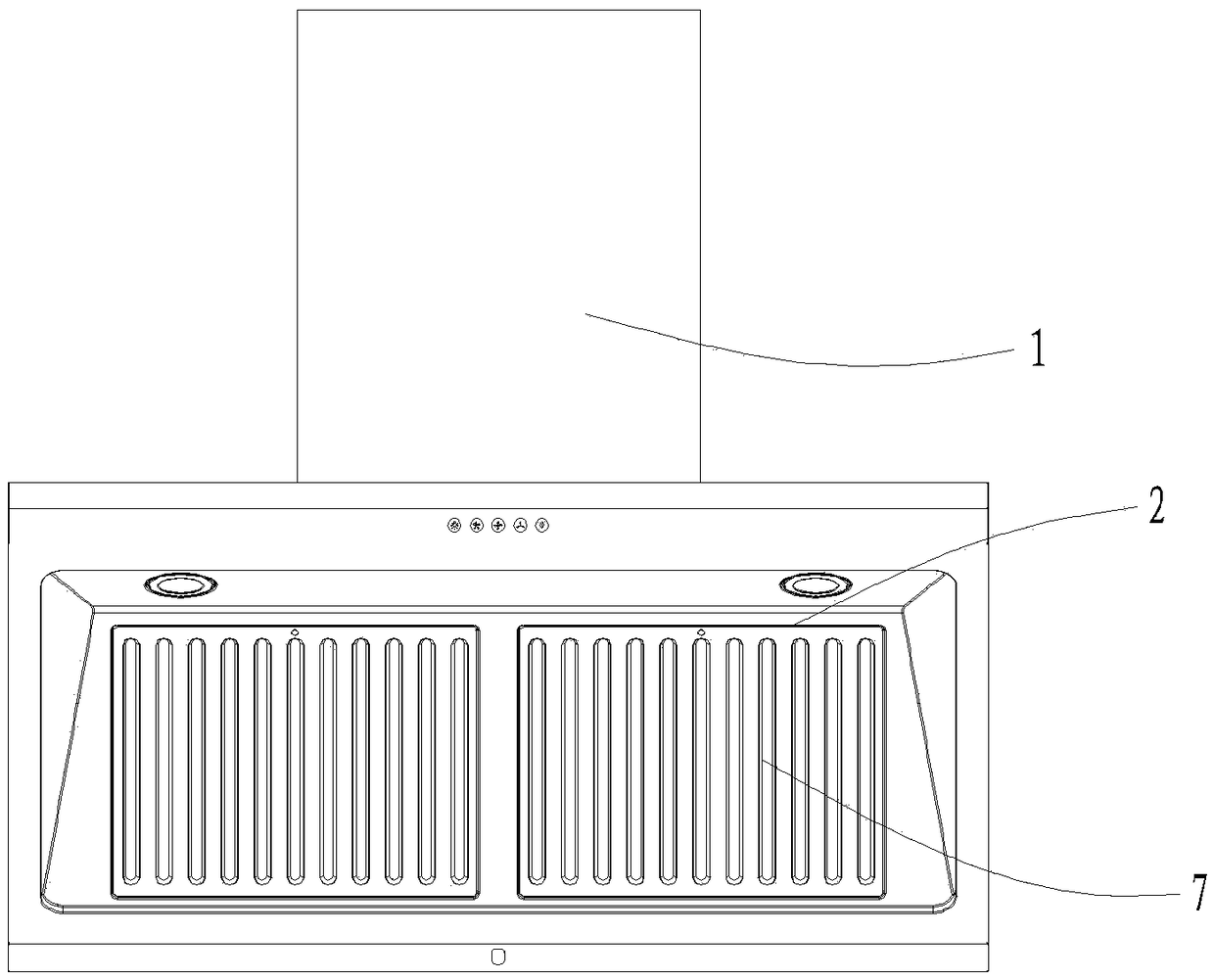

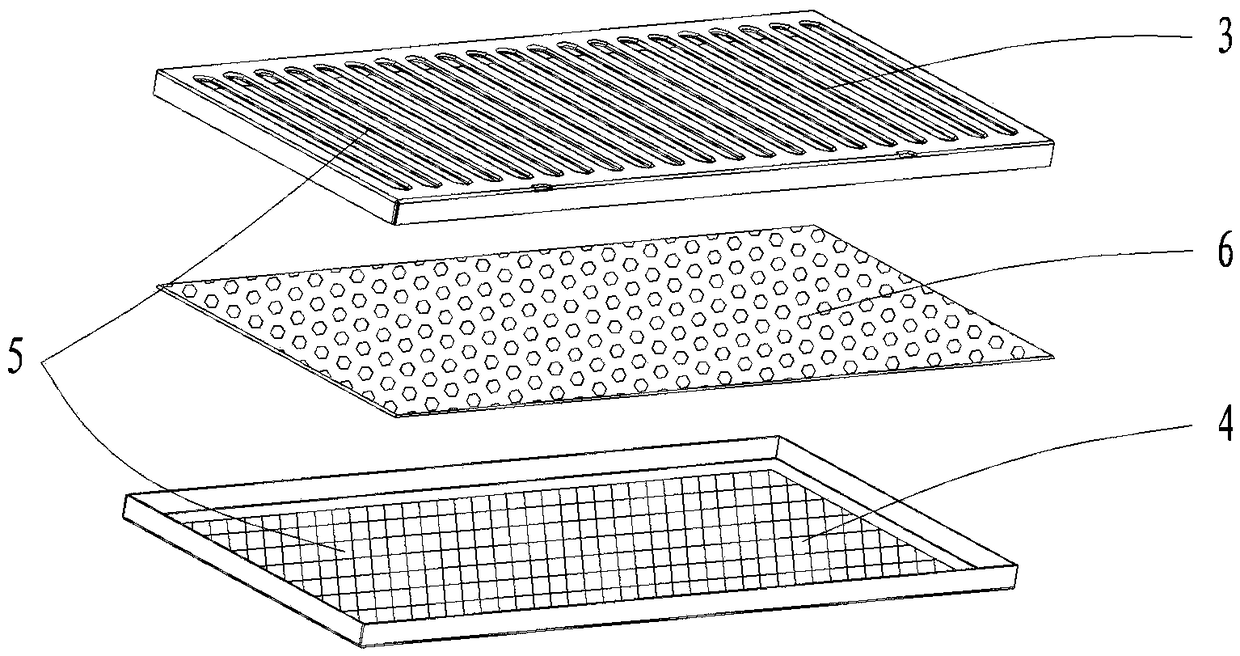

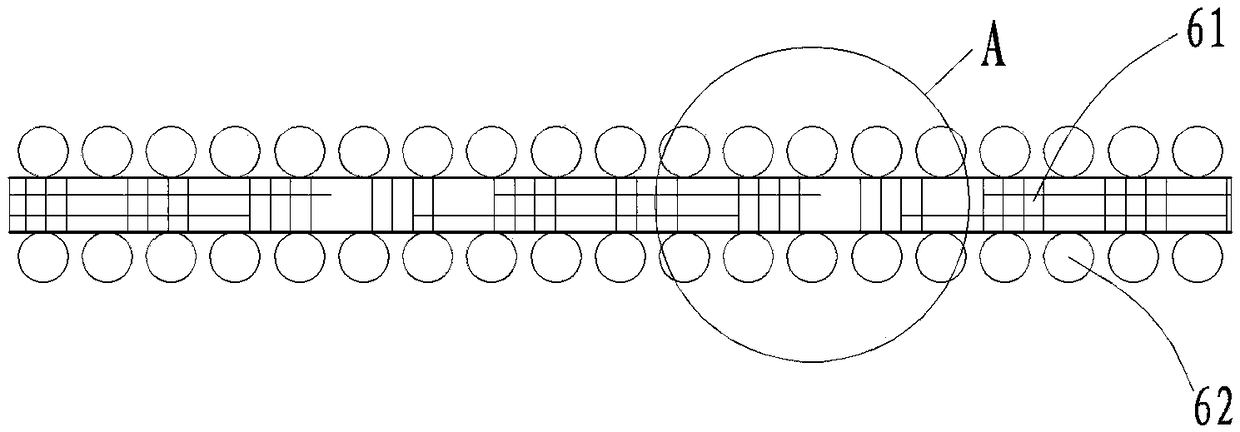

[0026] Embodiment one: if Figure 1 to Figure 4 As shown, this embodiment provides a range hood filter assembly, installed at the air inlet 2 of the main body of the range hood, including a first layer of filter 3 and a second layer of filter 4, the first layer of filter 3 and the The second layer of filter screen 4 is installed together, on the first layer of filter screen 3 and the second layer of filter screen 4 are respectively provided with some through holes 5, between the first layer of filter screen 3 and the second layer of filter screen 4 There is at least one oil-absorbing filter layer 6, and the oil-absorbing filter layer 6 includes an adhesive layer 61, and an oil-absorbing layer 62 is arranged on the surface of the adhesive layer 61.

[0027] In this embodiment, the filter assembly is detachably installed at the air inlet 2 of the main body of the range hood 1, and is used to filter and purify the oil smoke inhaled from the air inlet 2 of the main body of the ran...

Embodiment 2

[0043] Embodiment two: if Figure 1 to Figure 4 As shown, this embodiment provides a range hood, including a hood main body 1, an air inlet 2 is opened on the hood main body 1, and the above-mentioned filter assembly is detachably installed at the air inlet 2 7.

[0044] In the range hood of this embodiment, the filter screen assembly 7 as described above is detachably installed at the air inlet 2 of the hood main body, so that the range hood can strengthen the filtering and purification of oil fume, which can effectively reduce oil fume Enter the hood cavity or the inside of the fan to accumulate oil dirt and greasy dirt, and also reduce the discharge of oil fume to the outside, and the filter screen assembly 7 is detachably installed at the air inlet 2 of the main body of the hood, so that the filter screen After a period of use, it can also be easily disassembled for cleaning, so that it can continue to maintain its filtering and purification capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com