Device for testing seismic performance of fully asymmetric cross-shaped steel concrete joint

A technology of seismic performance and test device, which is applied in the direction of measuring device, vibration test, machine/structural component test, etc., can solve the problem of inability to measure the tensile force, and achieve the effect of ingenious design, low cost and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in combination with specific embodiments.

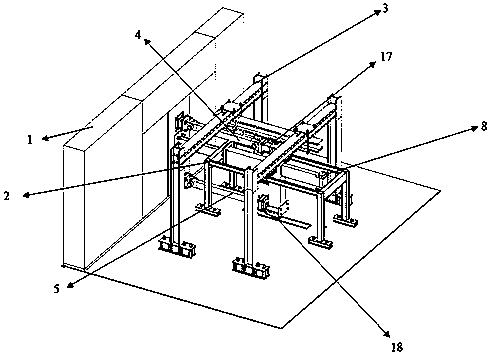

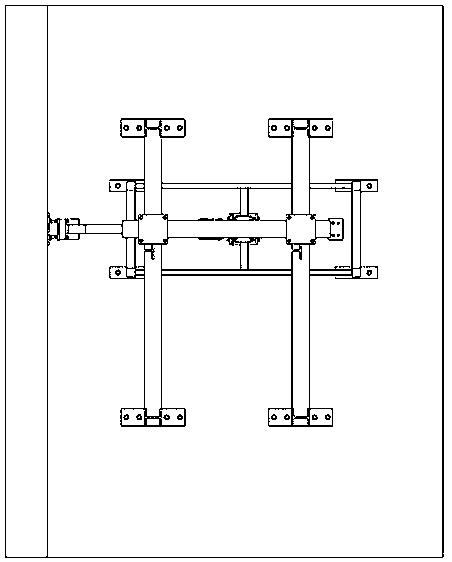

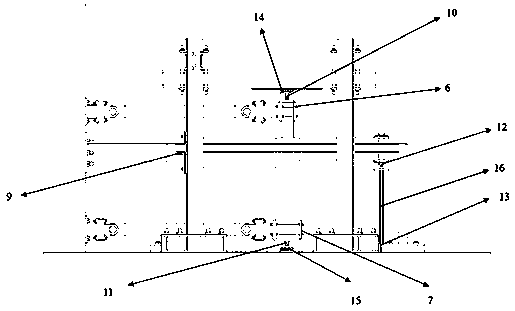

[0028] The invention relates to an anti-seismic performance test device of a completely asymmetrical cross-shaped steel concrete joint. The test object is a cross joint component, which is suitable for the anti-seismic performance test device of the component and can effectively clamp the test object.

[0029] The device includes a reaction wall 1, which is "inner" close to the reaction wall 1 and "outer" far away from the reaction wall 1. The cross node components are arranged vertically perpendicular to the reaction wall 1 . The top side of the cross node member is connected to the reaction wall 1 through the No. 1 servo actuator 4 which is perpendicular to the reaction wall 1 and horizontal, and the top surface of the cross node member is connected to the No. 2 door type reaction frame 3 set above it The No. 1 sliding support 17; the bottom side of the cross node memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com