A flexible packaging method for supercapacitors with a laminated structure

A technology of supercapacitor and stacked structure, which is applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problems of limiting the practical application of flexible electronics and unfavorable flexibility of supercapacitor devices, so as to ensure the impact sensitivity, eliminate the influence of interference, The effect of avoiding destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

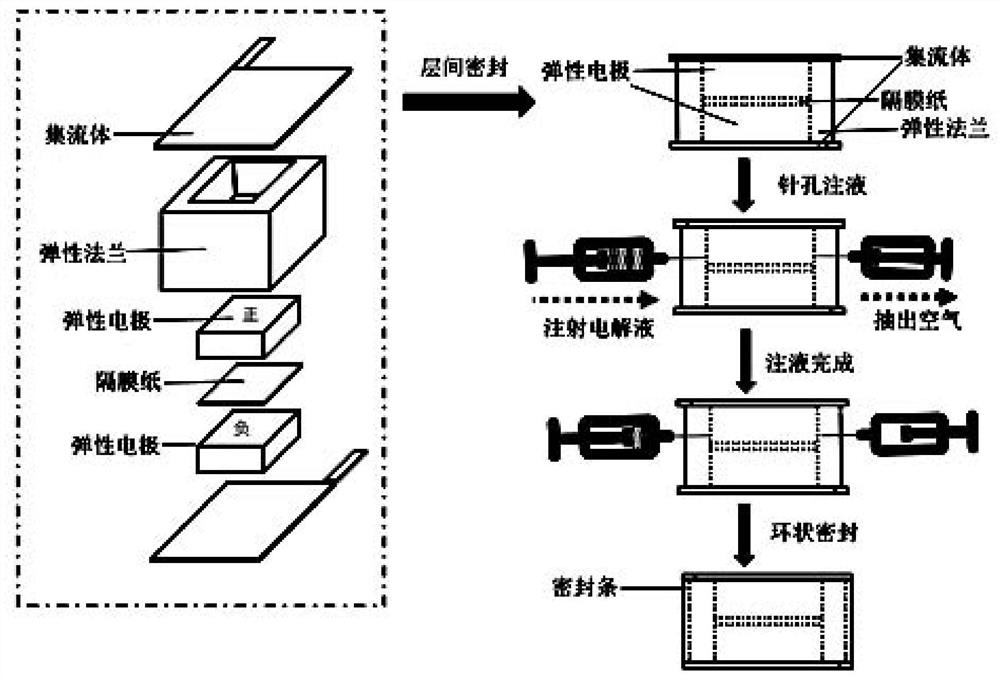

[0031] The present invention proposes a flexible packaging method for supercapacitors with a laminated structure, which will be described below with reference to the accompanying drawings.

[0032] The flexible packaging method of the supercapacitor with a stacked structure includes a single package and a multi-cell series package;

[0033] Such as figure 1 The single package shown includes the use of elastic flange structure to ensure that the electrodes are easily deformed under pressure; the liquid is injected through the pinhole to ensure the internal vacuum environment and prevent the stability of the package from being damaged due to long-term slow gas production; Sealing to further ensure the reliability of the device packaging structure; the specific steps are as follows:

[0034] (1) The current collector, elastic positive electrode, separator, elastic negative electrode and current collector are obtained by cutting with a slicer; the length and width of the elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com