Wafer level packaging structure of chip, and preparation method of wafer level packaging structure

A wafer-level packaging and chip technology, applied in electrical components, circuits, semiconductor devices, etc., to overcome chip short-circuits, improve welding strength and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

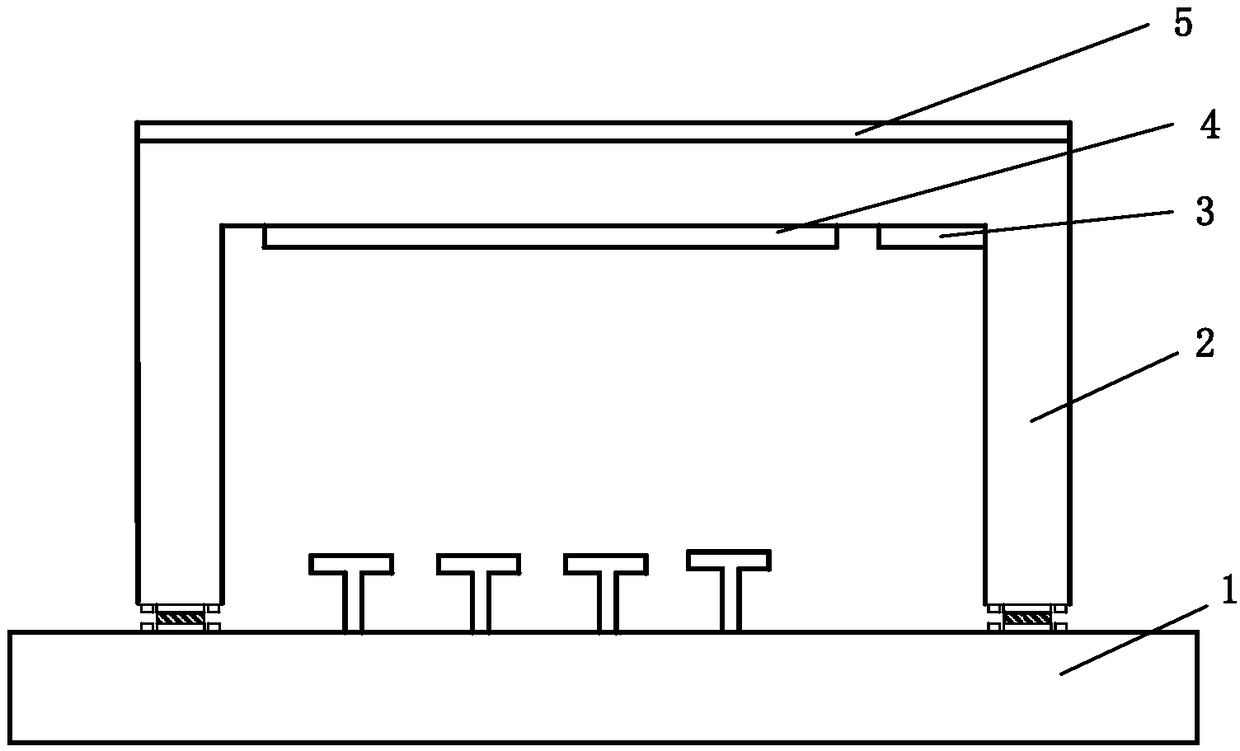

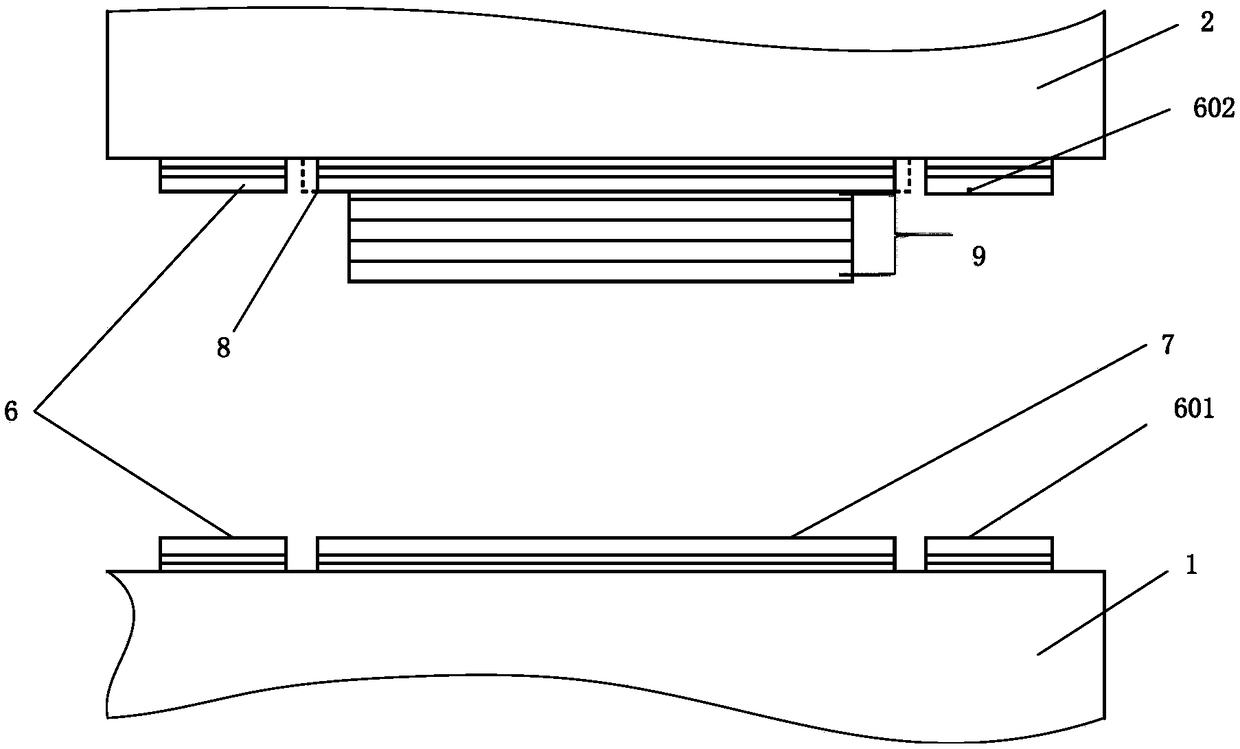

[0036] This embodiment provides a chip wafer-level packaging structure, including a chip 1, and also includes a vacuum cavity structure, and the vacuum cavity structure encapsulates the chip 1 inside; wherein, the vacuum cavity structure includes a silicon chip supporting shell 2, a silicon chip The upper surface of the support shell 2 is provided with a first anti-reflection film 5, and the inner surface of the silicon chip support shell 2 is provided with a second anti-reflection film 4 at a position opposite to the first anti-reflection film 5, and the second anti-reflection film 4 A getter film 3 is provided next to the chip 1; a first solder ring 7 is provided on the periphery of the chip 1, a second solder ring 8 and a third solder ring are provided on the bottom of the silicon chip supporting shell 2, and the first solder ring 7 and the second The solder ring 8 and the third solder ring 9 are sealed by bonding in a vacuum environment.

[0037] In this embodiment, the en...

Embodiment 2

[0045] A method for preparing a wafer-level packaging structure of a chip, comprising the following steps:

[0046]Step 1, one side of the silicon wafer supporting shell 2 is first made a scribe line by photolithography and etching; the other side of the silicon wafer supporting shell 2 is made a 100 μm deep cavity by photolithography and etching;

[0047] Step 2, vapor-depositing the second anti-reflection film 4 and the getter film 3 on the bottom of the deep cavity;

[0048] Step 3, evaporate the second solder ring 8, the second anti-overflow bar 602 and the third solder ring 9 on the step of the deep cavity;

[0049] Step 4, making a scribe line on the backside of the silicon wafer of the chip 1 by photolithography and etching; evaporating the first solder ring 7 and the first anti-overflow strip 601 on the front side of the silicon wafer of the chip 1;

[0050] Step 5, vacuumize the silicon wafer supporting the shell 2 and the silicon wafer of the chip 1 in the bonding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com