Cable bracket device used in ship construction and mounting and use method thereof

A cable bracket and cable installation technology, which is applied in the direction of electrical components, etc., can solve the problems that the length and height cannot be fully adapted to meet the needs, prolong the ship construction dock cycle, and cannot guarantee the cable bending radius, etc., so as to reduce the amount of subsequent operations , Good application value, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The backing plate device used between the cable bracket and the cable in ship construction will be further elaborated below in conjunction with the accompanying drawings and specific examples, in order to understand the structure type and use of the backing plate device more clearly way, but it should not be used to limit the present invention to ships

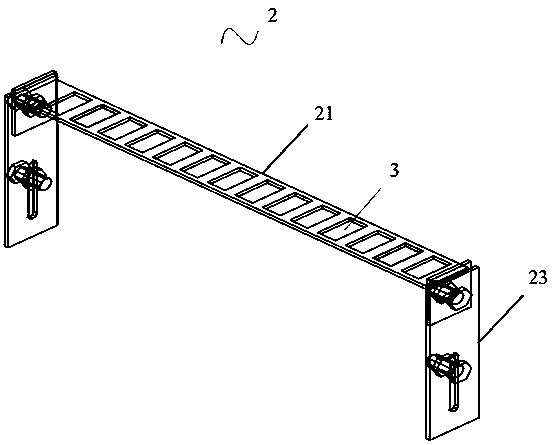

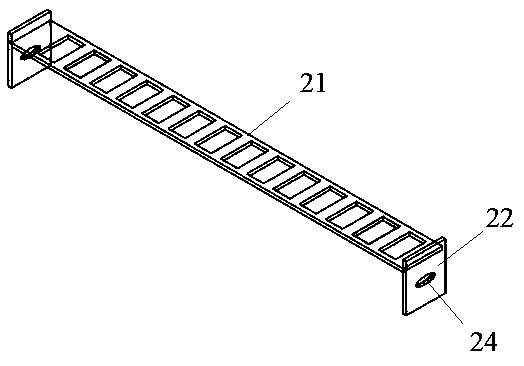

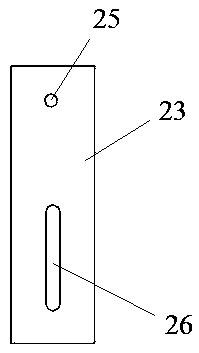

[0024] Such as Figure 1-Figure 6 As shown, this embodiment is used for the cable bracket device in shipbuilding, and the device includes a cable bracket 1, and the cable bracket 1 includes a cable installation plate 11, a bracket outer guide plate 12 and a support leg 13, and the cable installation The two ends of the plate 11 are respectively connected with the bracket outer guide plate 12, the supporting legs 13 are installed on the end of the bracket outer guide plate 12, and one end of the cable bracket 1 is provided with a cable backing plate 2, and the cable backing plate 2 Including a panel 21, a side plate 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com