A kind of overlapping connection type stator core and preparation method thereof

The technology of a stator core and its manufacturing method is applied in the field of overlap-connected stator core and its preparation, which can solve problems such as magnetic flux leakage, reduction of motor efficiency, and blockage of electromagnetic field circuits, so as to reduce production costs, improve motor efficiency, and magnetic circuit Unobstructed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

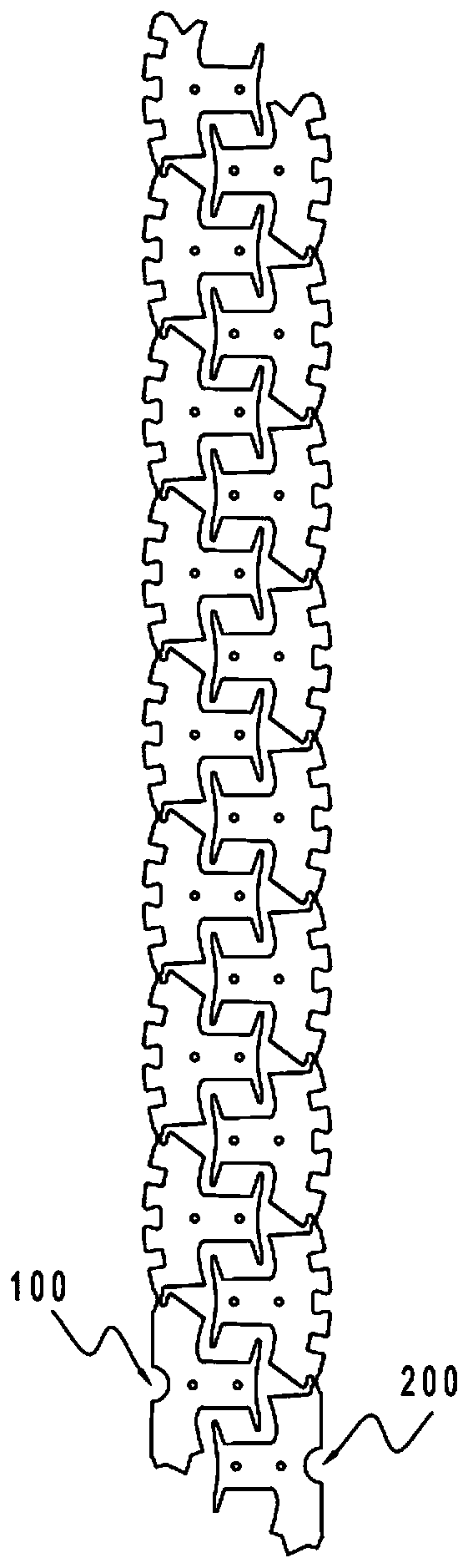

[0027] The stator iron core provided by the present invention is formed by interlacing two kinds of connected punching sheets which are inserted and sleeved; the seams of adjacent layers are not on the same axial section. Thus, while improving the performance of the motor, the material utilization rate is improved and the cost of the motor is reduced.

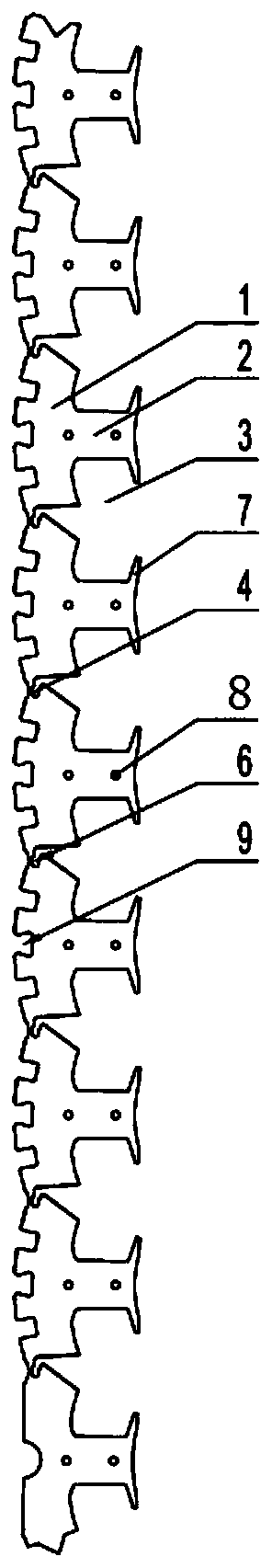

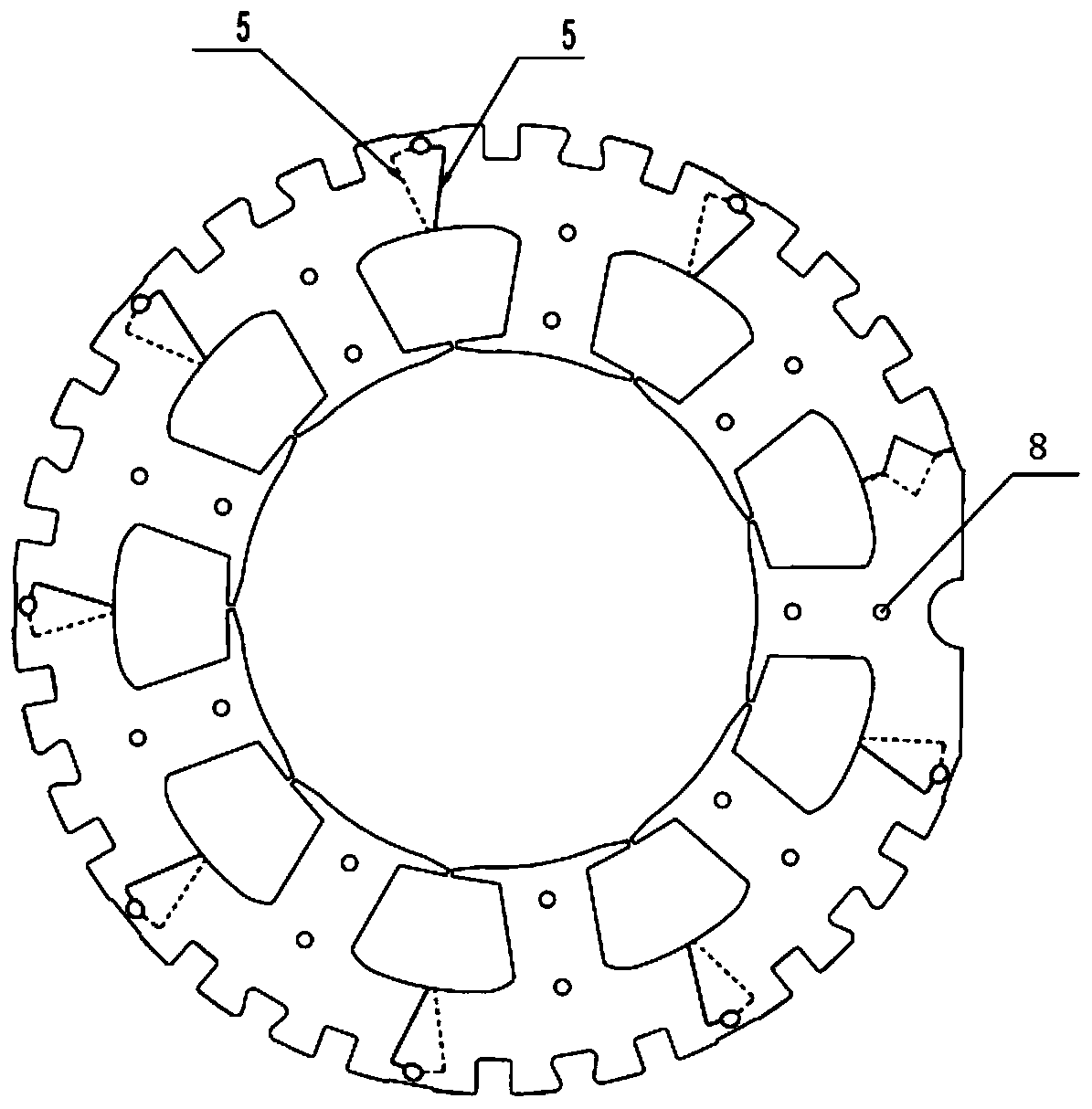

[0028] Figure 1-3 One embodiment of the connected lamination structure for the stator core of the present invention is shown. see figure 1 , the connected punching plate includes N punching units connected to each other through the connecting portion 4, the punching unit includes a yoke portion 1 and a tooth portion 2, and a stator slot 3 is formed between adjacent tooth portions 2. see figure 2 , after forming a loop, the adjacent yokes contact each other to form a seam 5, and the seams of adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com