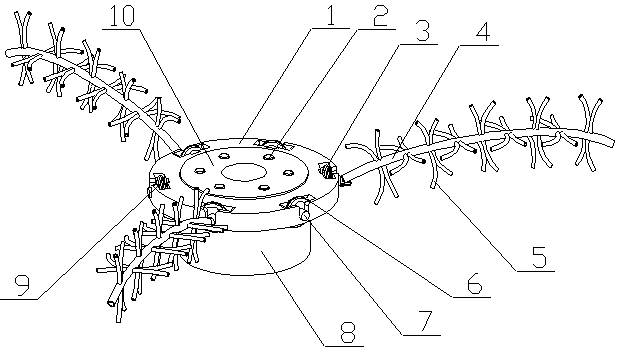

Circular ventilation opening shutter cleaning brush disc

A technology for cleaning brushes and air vents, which is applied in the field of public health, and can solve the problems of large brushes, inconvenient transportation, and poor cleaning effect, and achieve the effect of improving cleaning efficiency, good cleaning effect, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

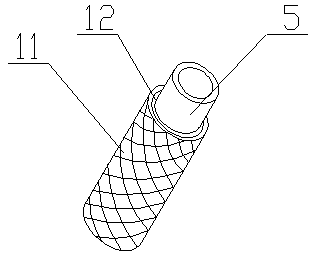

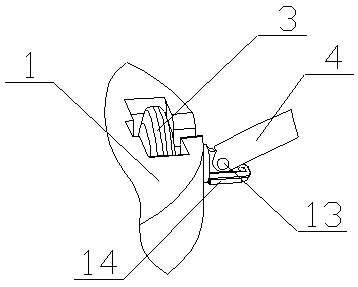

[0021] A circular air vent louver cleaning brush disc of the present invention is realized in the following way: a circular air vent louver cleaning brush disc of the present invention consists of a main disc body (1), an anti-slip rubber pad (2), a driving wheel (3), Cleaning brush rod (4), cleaning pipe (5), accommodation tank (6), rotating shaft (7), connecting sleeve (8), auxiliary wheel (9), rotary support disc (10), outer fiber layer (11) , metal mesh (12), connecting shaft (13), limit tray (14), bearing (15), blade (16) and support sleeve (17), the main disc body (1) is placed on the connecting sleeve (8) At the top, there is a mounting groove on the inner side of the main disc body (1), and the mounting groove extends to the inner side of the connecting sleeve (8). A plurality of blades (16) are respectively placed in the mounting groove and distributed in a ring shape. (16) is connected with the main disc body (1), and the supporting sleeve (17) is placed in the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com