A kind of activated carbon grinding process

A grinding process and activated carbon technology, applied in chemistry, grain processing, etc., can solve the problem of poor quality of activated carbon, and achieve the effect of improving the quality of grinding, sufficient grinding, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

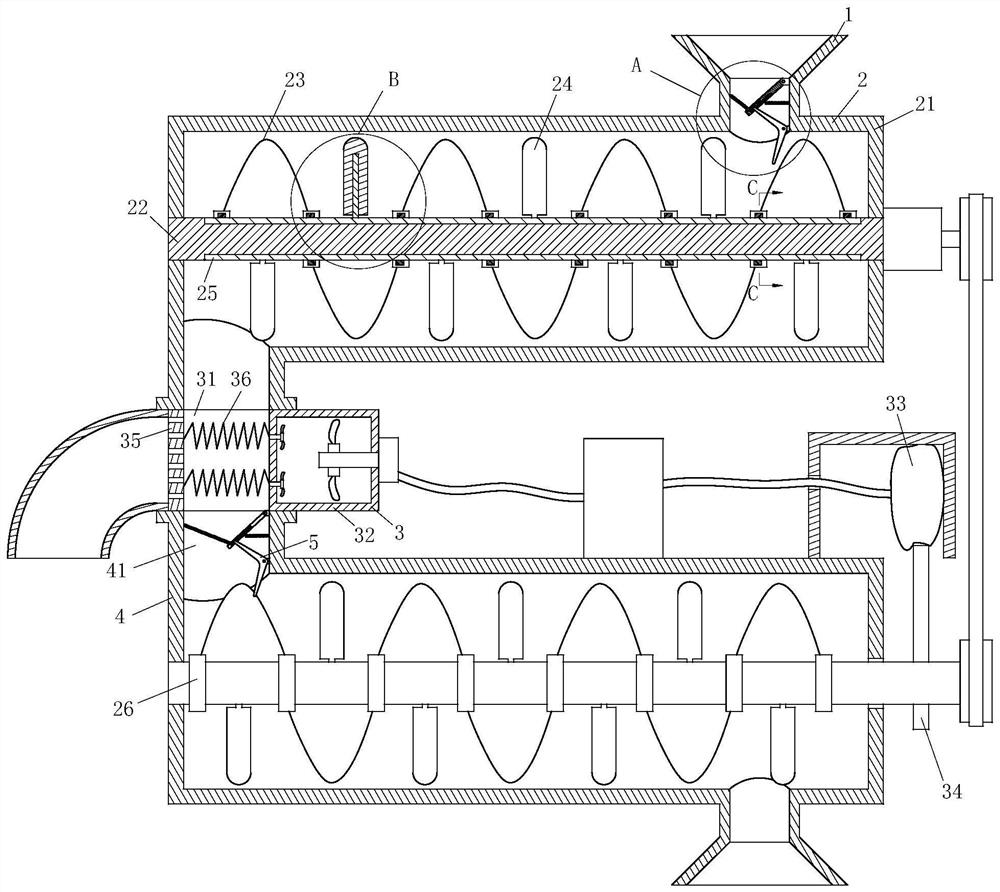

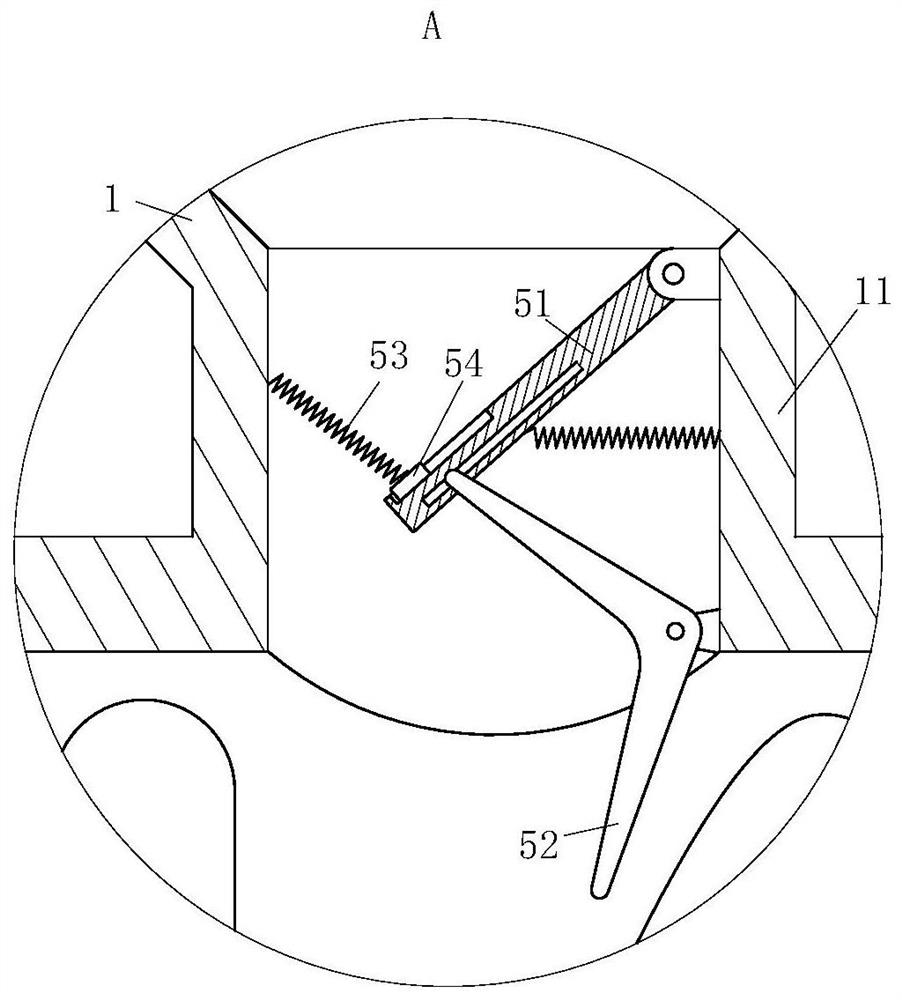

[0028] use Figure 1-Figure 5 An activated carbon grinding process according to an embodiment of the present invention is described as follows.

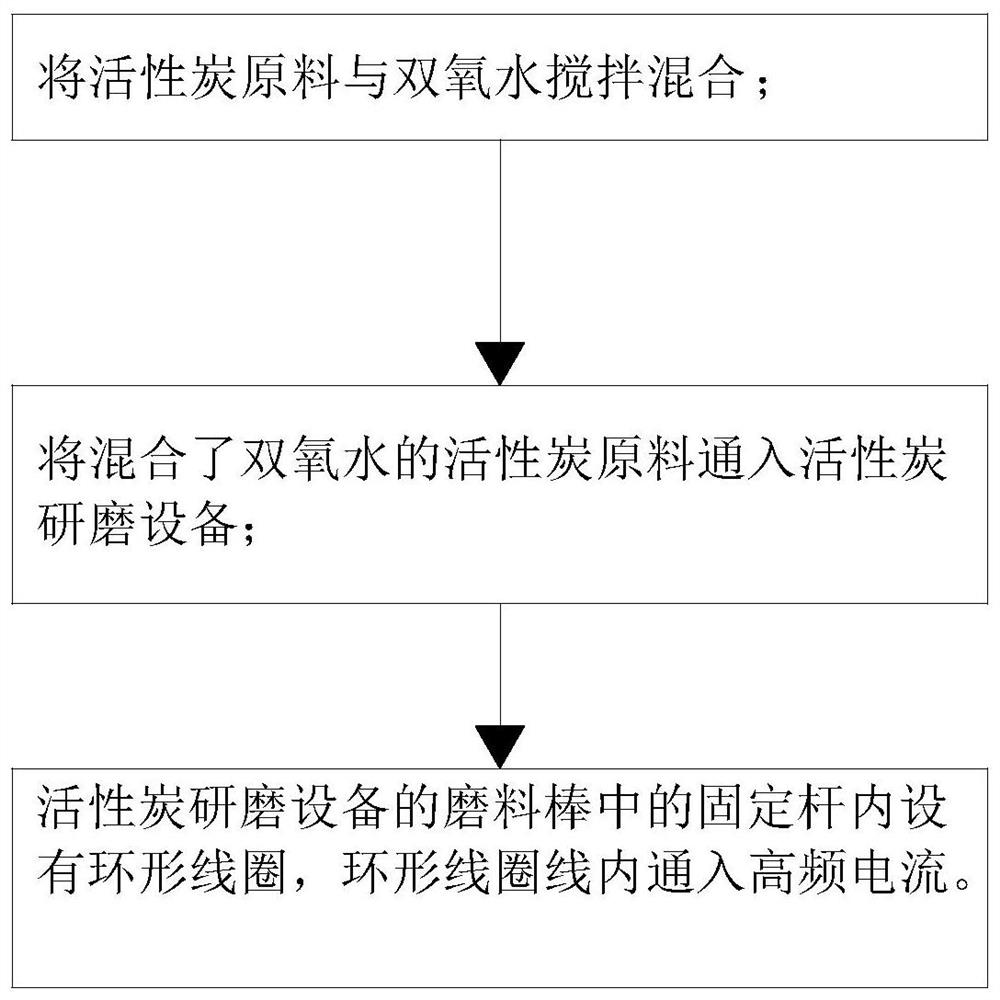

[0029] Such as figure 1 , figure 2 and Figure 5 Shown, a kind of activated carbon grinding process of the present invention, this process comprises the steps:

[0030] S1: Stir and mix the activated carbon raw material with hydrogen peroxide; by stirring the activated carbon raw material and hydrogen peroxide, use hydrogen peroxide to kill the bacteria on the surface of the activated carbon raw material, and at the same time clean the dirt on the surface of the activated carbon raw material to improve the quality of the subsequent activated carbon produced;

[0031] S2: Pass the activated carbon raw material mixed with hydrogen peroxide in S1 into the activated carbon grinding equipment; through the use of this equipment, the quality of activated carbon raw material grinding is improved, and the ground activated carbon meets the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com