Patents

Literature

43results about How to "Avoid re-contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

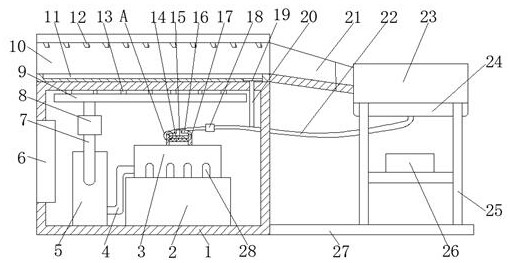

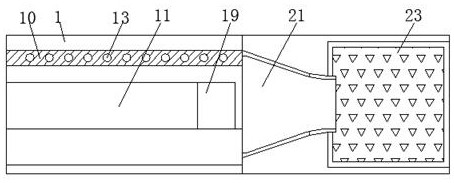

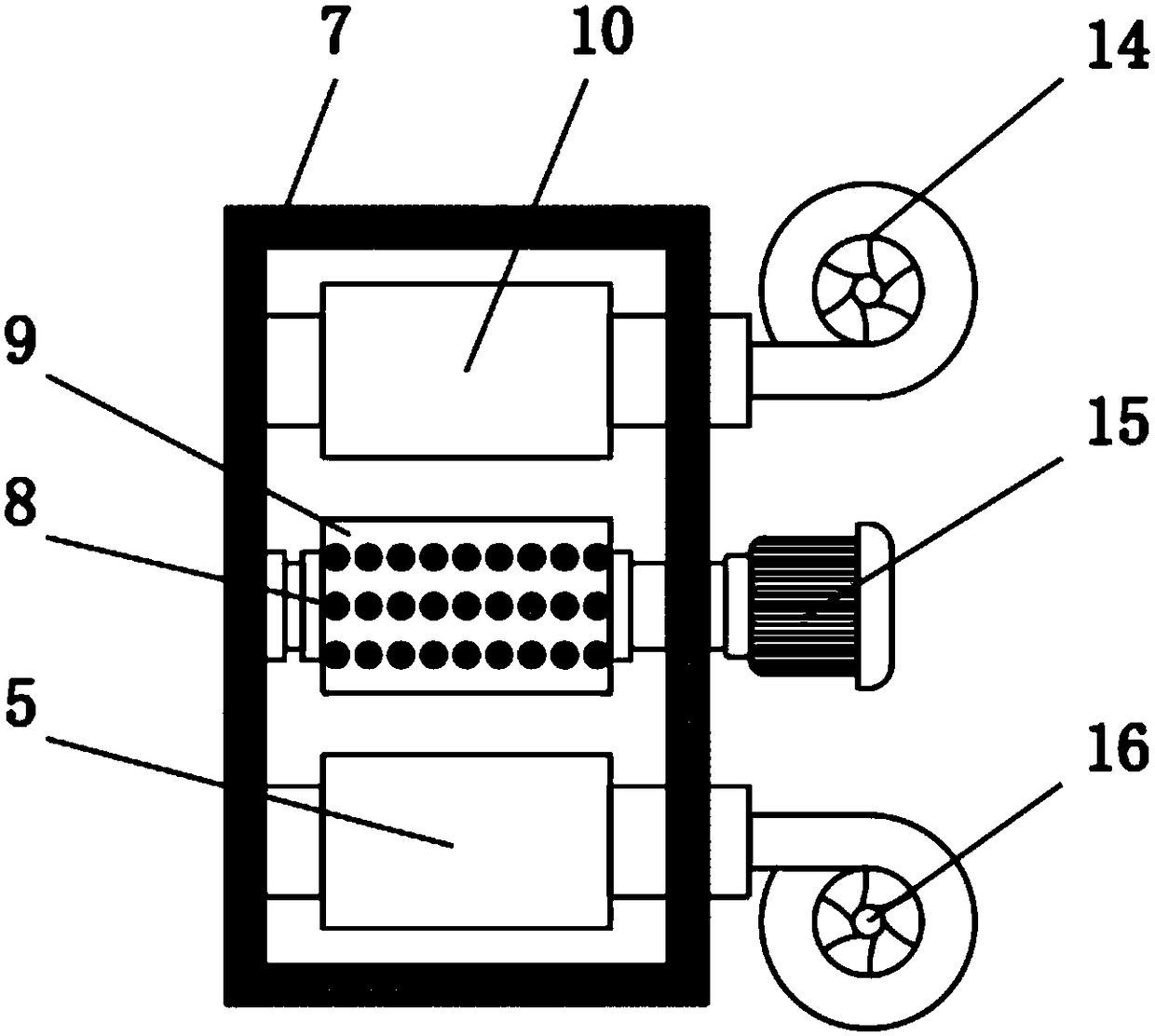

Intelligent fresh air and indoor air synchronous purification equipment and intelligent fresh air and indoor air synchronous purification method

InactiveCN104833001APurification fitWon't penetrateMechanical apparatusSpace heating and ventilation safety systemsPurification methodsIndoor air quality

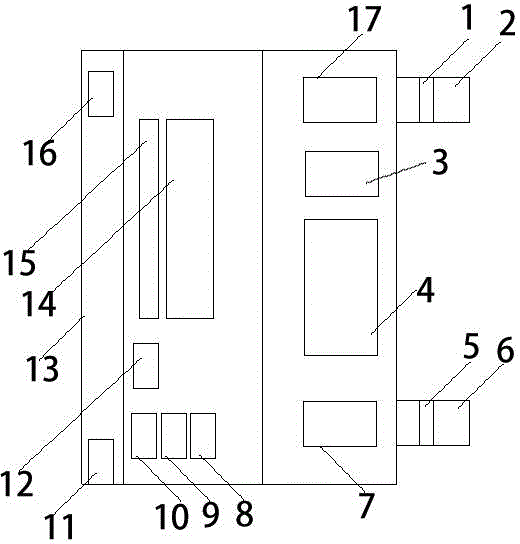

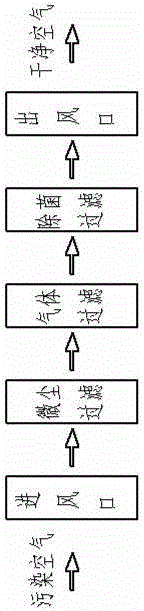

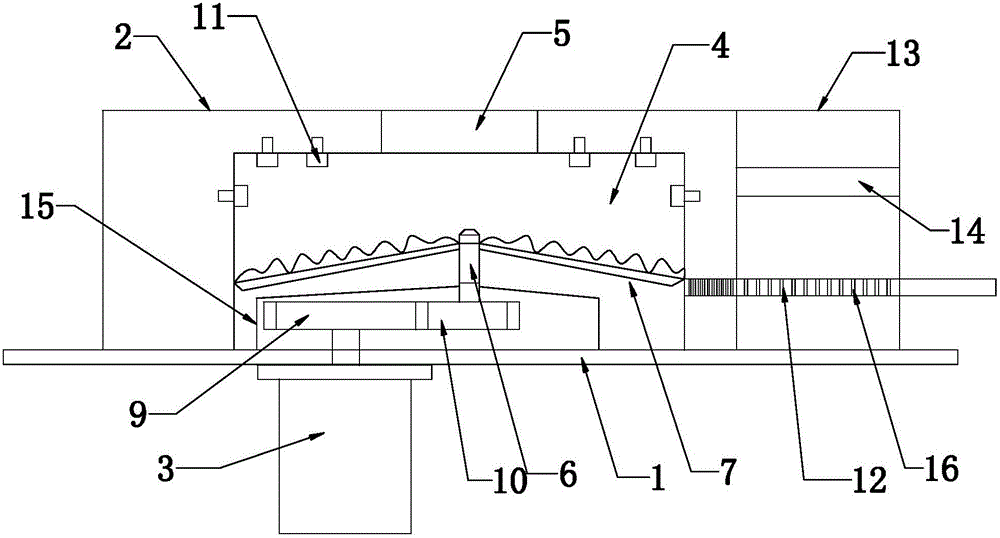

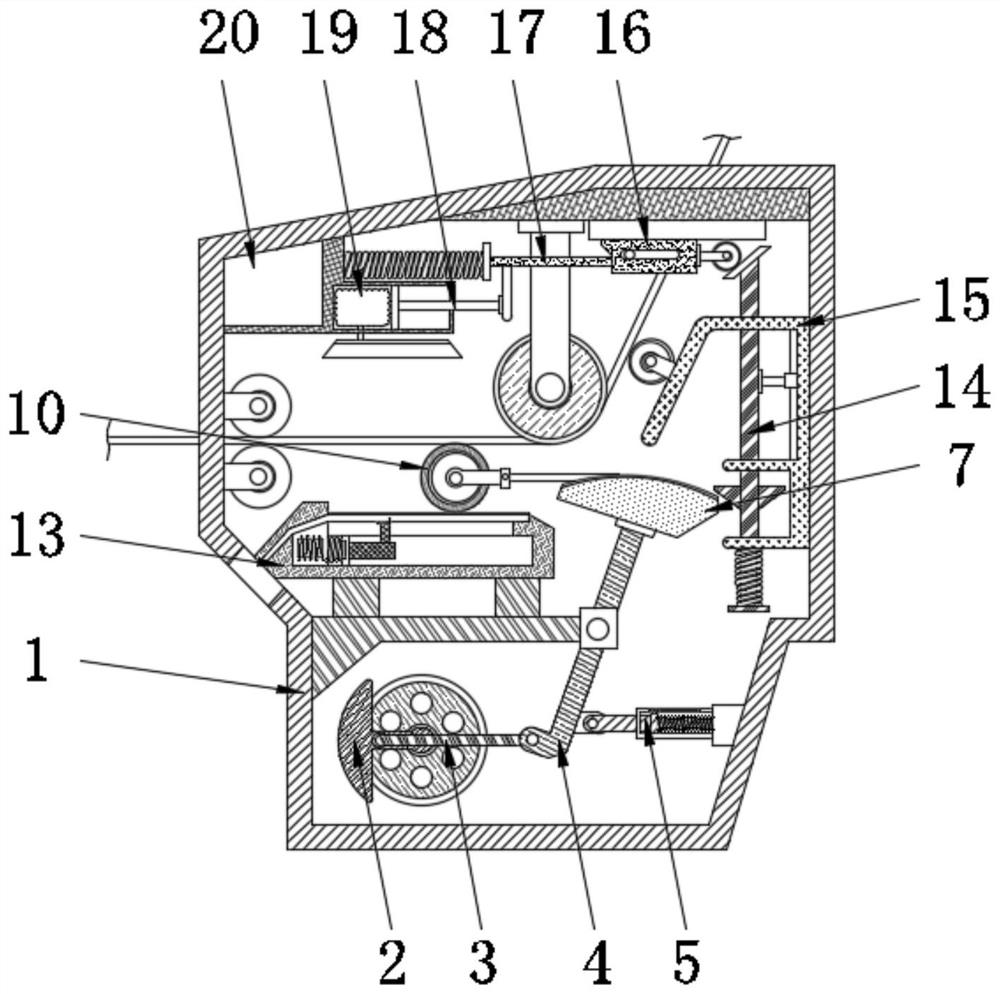

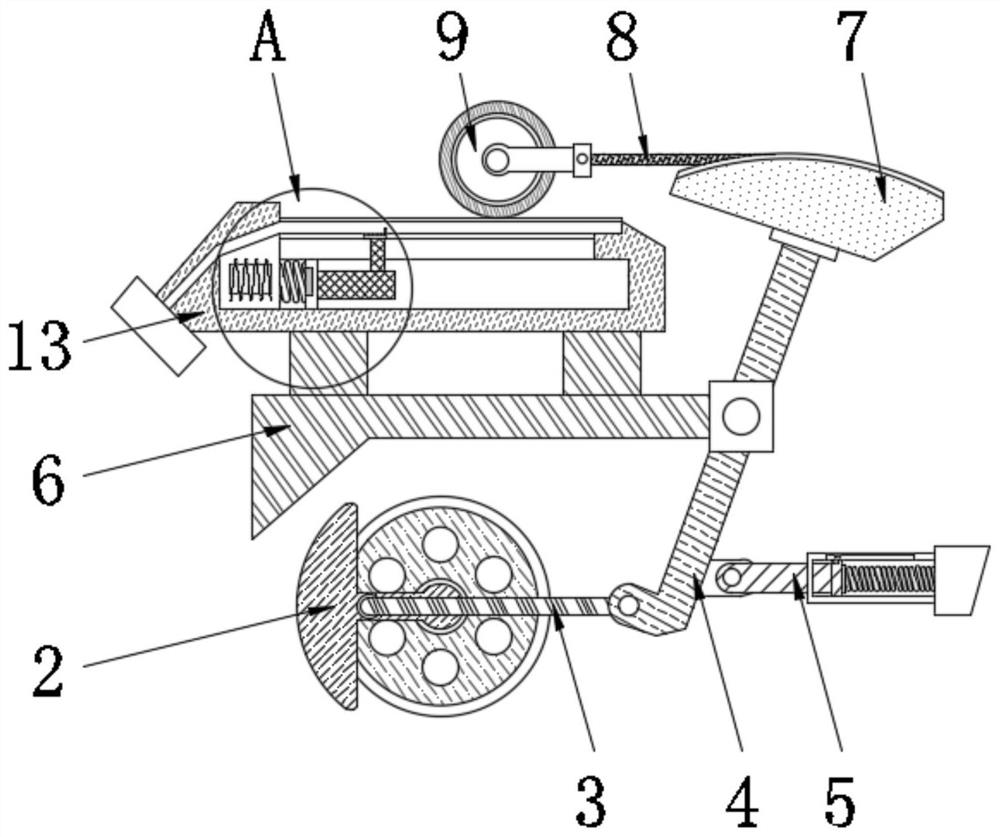

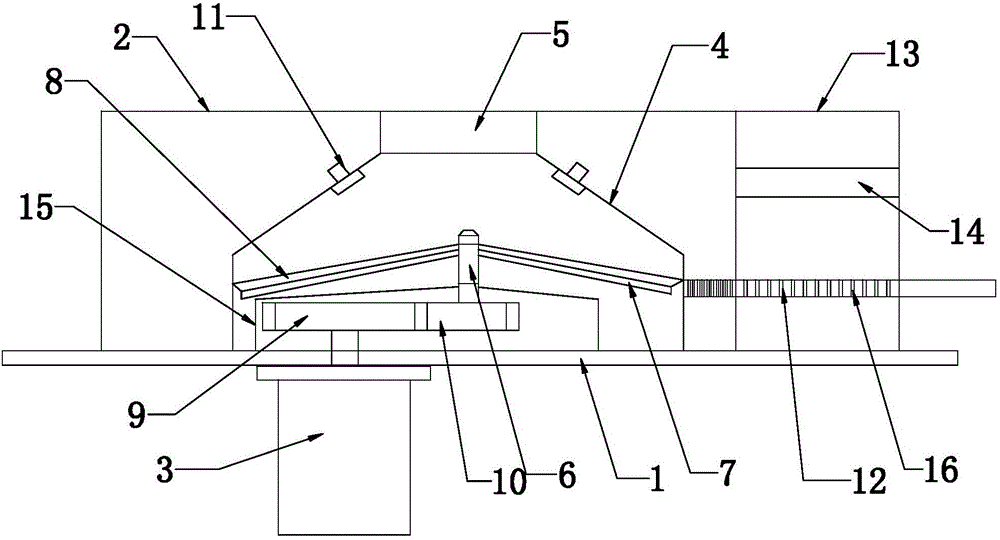

The invention discloses a piece of intelligent fresh air and indoor air synchronous purification equipment and an intelligent fresh air and indoor air synchronous purification method. The equipment comprises a main case 13. The main case 13 is equipped with a fresh air inlet pipe 2, and the fresh inlet air pipe 2 is equipped with a valve device 1 used for opening and closing the air inlet pipe. The main case 13 is further equipped with an exhaust pipe 6, and the exhaust pipe 6 is equipped with a valve device 5 used for opening and closing the exhaust pipe. The main case is internally provided with an intelligent detection component 8 for air detection, a control component 9, an intake fan 17, an exhaust fan 7, an indoor circulation purification fan 14, an indoor air filtration and purification component 15, a fresh air filtration and purification component 3, a heat exchange component 4, an operation display component 12, and an indoor air quality display component 10. The equipment and the method of the invention can achieve a better purification effect, and are suitable for air purification under the condition of serious outdoor air pollution in our country at present stage.

Owner:BEIJING SYNTEC SCI & TECH DEV CO LTD

Anti-fouling and self-cleaning two-in-one coating

InactiveCN101289583AWipe off easilyNot easy to attachAntifouling/underwater paintsPaints with biocidesOrganic solventPublic Facility

The invention discloses anti-fouling self-cleaning two-into-one coating, which effectively removes stains, has the anti-adhesive performance, and does not damage coating on the original lacquered surfaces. The invention is characterized in that: organic solvent is utilized to soften and dissolve stains such as non cohesive gel, dirt and so on, can form non-adhesive coating, and can completely solve the problem of city psoriasis; at the same time, the coating can also be independently used as anti-adhesive coating, and has good application prospect. The coating can be widely used for municipal and public facilities, and ensure that the coated surfaces are difficult to be polluted and are easy to clean.

Owner:邢少祥

Preparation method of chelating dispersant

The invention relates to a preparation method of a chelating dispersant. The preparation method comprises steps as follows: a, 10 parts of maleimide and 12 parts of acrylamide are dissolved with 65 parts of deionized water, 0.2 parts of sodium persulfate is dissolved with 30 parts of deionized water, and a solution is formed for later use; b, 20 parts of dodecyl polyoxyethylene ether, 15 parts of maleic anhydride sodium monoester, 15 parts of diallylamine and 234 parts of deionized water are added to a reactor, dissolved and heated to 70 DEG C; c, 1 / 3 of a maleimide and maleicamide aqueous solution in volume and 1 / 4 of a sodium persulfate water solution in volume are added to a reaction kettle and kept at the temperature for 30 min; d, the remaining maleimide and maleicamide aqueous solution, the remaining sodium persulfate water solution and 20 parts of acrylic acid are dropwise added within 2 h and kept at 80 DEC G, and the mixture reacts for 2 h; e, the temperature of the reactor is reduced to 30 DEG C, 8 parts of sodium hydroxide are added firstly, 14 parts of carbon disulfide are added after dissolution, the mixture reacts for 3 h and is filtered, and the chelating dispersant is obtained.

Owner:秦瑶

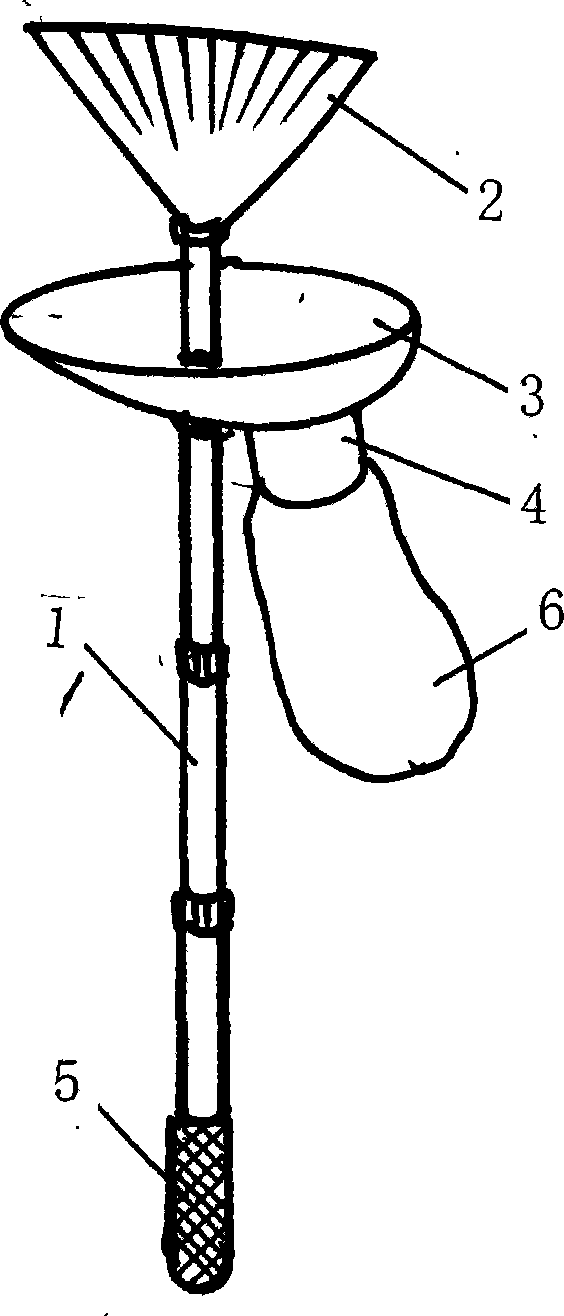

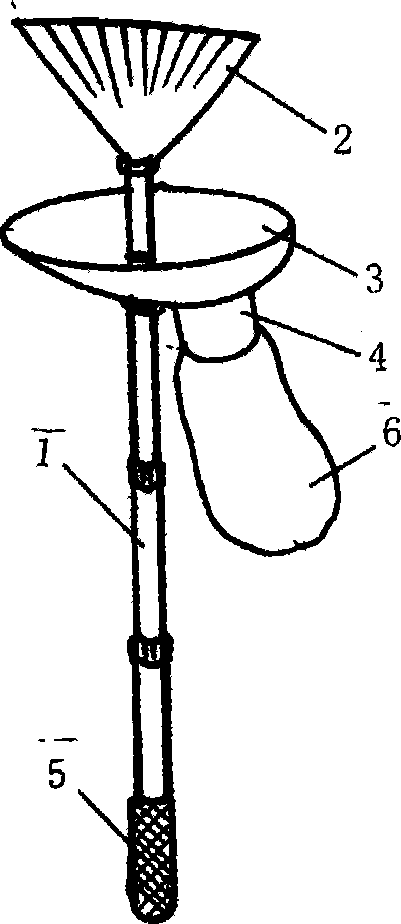

Roof ceiling cleaning device

InactiveCN101987004AAvoid re-contaminationGood for healthCarpet cleanersFloor cleanersEngineeringHuman health

The invention provides a roof ceiling cleaning device. A dust receiving hopper is arranged at the front end of a broom with a telescopic handle lever, and is provided with a hopper opening which can be sleeved with a dust bag; and an antislip handle grip is arranged at the tail end of the telescopic handle lever. The roof ceiling cleaning device can be used for cleaning dust on a roof ceiling and the like; and the cleaned dust can directly fall into the dust receiving hopper, and is collected in the dust bag through the hopper opening for unified treatment, so the roof ceiling cleaning device can avoid the raised dust causing secondary pollution in the cleaning, and is favorable for human health and environmental health.

Owner:刘方怡

Maintenance method for high-pressure casting mold

The invention discloses a maintenance method for a high-pressure casting mold. The maintenance method comprises the steps of air injection and water drainage, concentrated hydrochloric acid brushing, water injection and cleaning, and the like, wherein the air injection and water drainage step is that water is injected into waterways and micro holes in the mold through a drainage hole and an exhaust hole in the mold at the air pressure of 0.45 to 0.55 MPa till water in the mold is drained; the concentrated hydrochloric acid brushing step is that the surface of the mold is brushed with concentrated hydrochloric acid through a fur brush; and the water injection and cleaning step is that water is injected into the waterways in the mold for 30 to 60 min through the drainage hole in the mold at the water pressure of 0.2 to 0.4 MPa, and the surface of the mold is cleaned through clean water at the same time. According to the maintenance method, the operation is simple, the cost is low, the mold darkening is avoided while the mold surface is cleaned, the mold appearance is improved, the drainage and exhaust effect of the mold is improved while the micro holes of the mold are dredged, the service life of the mold is prolonged, and the maintenance method can be reutilized and can be popularized and applied to maintenance of ceramic molds.

Owner:JOMOO KITCHEN & BATHROOM

High pressure pouring mold surface oxidization treatment method

InactiveCN106513369AImprove water and ventilation effectGood lookingDrying gas arrangementsCleaning using liquidsSodium chlorateSodium hypochlorite solution

The invention discloses a high pressure pouring mold surface oxidization treatment method which comprises the steps of air injection drainage, brushing of a sodium hypochlorite solution, water injection cleaning and the like. According to air injection drainage, air with the air pressure being 0.45-0.55 MPa is injected into water channels and micro-holes in a mold through drainage and air exhaust holes in the mold till moisture in the mold is fully drained. According to brushing of the sodium hypochlorite solution, the sodium hypochlorite solution is brushed on the surface of the mold through a hairbrush. According to water injection cleaning, water with the hydraulic pressure being 0.2-0.4 MPa is injected into the water channels in the mold through water drainage holes in the mold, and the surface of the mold is washed through clean water at the same time. The high pressure pouring mold surface oxidization treatment method is easy to operate and low in cost, mold oxidization and blocking of the micro-holes in the mold are prevented while mold oxidization is eliminated, the appearance of the mold is improved, the service life of the mold is prolonged, and the oxidization treatment method can be reused and applied and popularized to ceramic mold oxidization treatment.

Owner:JOMOO KITCHEN & BATHROOM

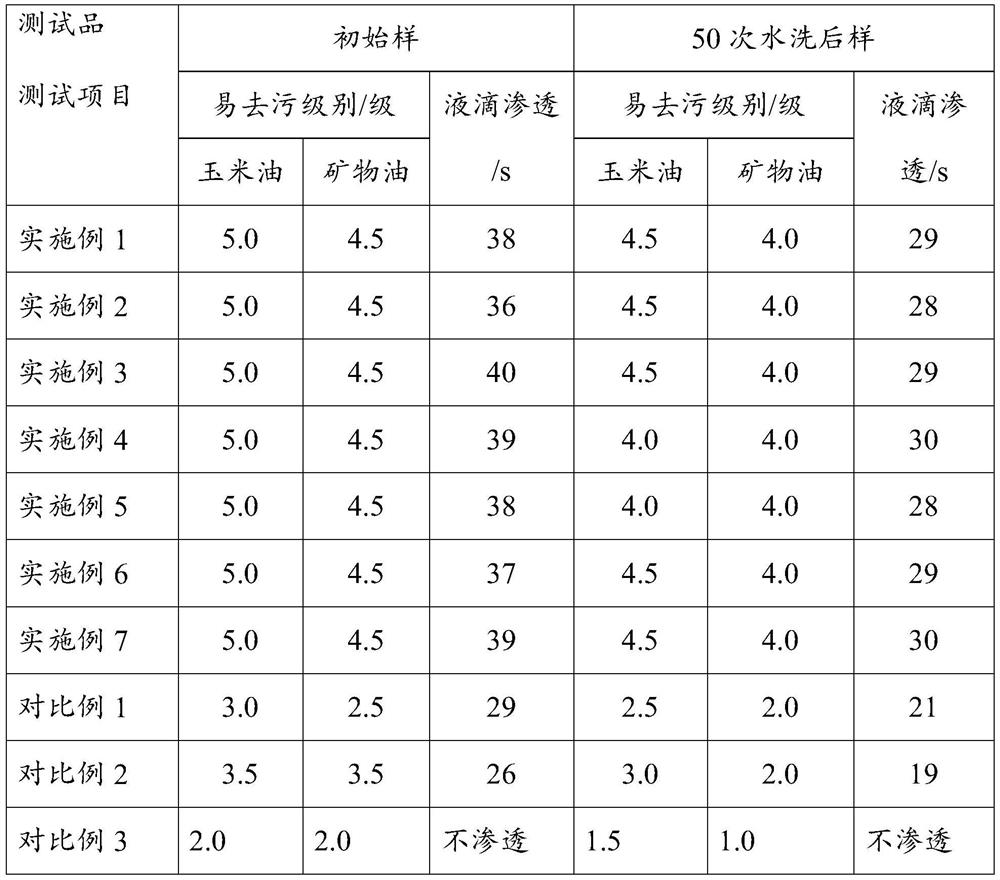

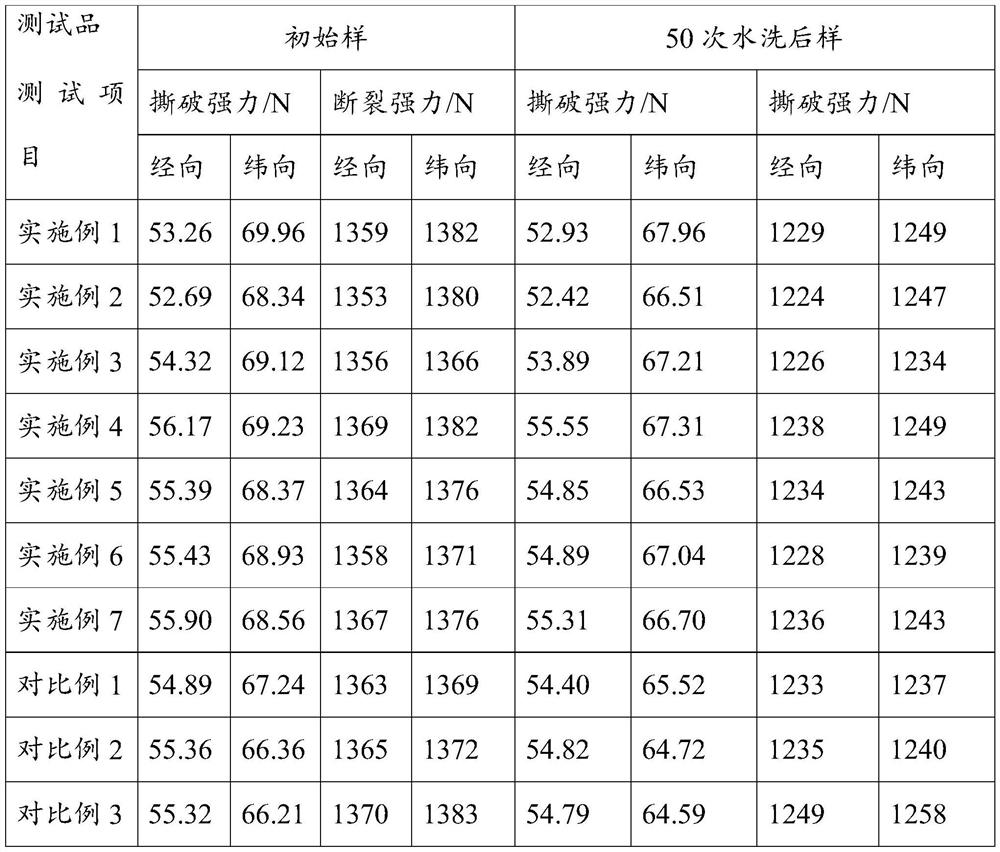

Hydrophilic polyester masterbatch facilitating decontamination and preparation method of hydrophilic polyester masterbatch

ActiveCN110079059AImprove water absorption and retention capacityPrevent re-contaminationMonocomponent polyesters artificial filamentArtifical filament manufactureCross-linkPolyester

The invention discloses hydrophilic polyester masterbatch facilitating decontamination and a preparation method of the hydrophilic polyester masterbatch. The hydrophilic polyester masterbatch is prepared from raw materials in parts by mass as follows: 90-96 parts of carrier resin and 4-10 parts of super absorbent resin, wherein the super absorbent resin is a starch-acrylic acid-acrylamide-fluorinated acrylic ester grafted copolymer. The super absorbent resin can form a three-dimensional space network with excellent water absorption and water retention properties; after the starch is grafted with fluorinated acrylic ester with longer carbon chains, fluorocarbon groups of fluorinated acrylic ester in a dry state can be directionally arranged on the surface of starch, low surface tension is formed and oil repellency is produced, however, the fluorocarbon groups are not directionally arranged in a wet state, so that the three-dimensional space network formed by cross-linking acrylic acid and acrylamide is exposed, and the polyester masterbatch is enabled to be hydrophilic and has functions of removing contamination and preventing secondary contamination. Therefore, hydrophilic and oil-repelling functions of the super absorbent resin are obtained, and the hydrophilic polyester masterbatch facilitating decontamination can be obtained.

Owner:TONGXIANG HUACAI MASTERBATCH

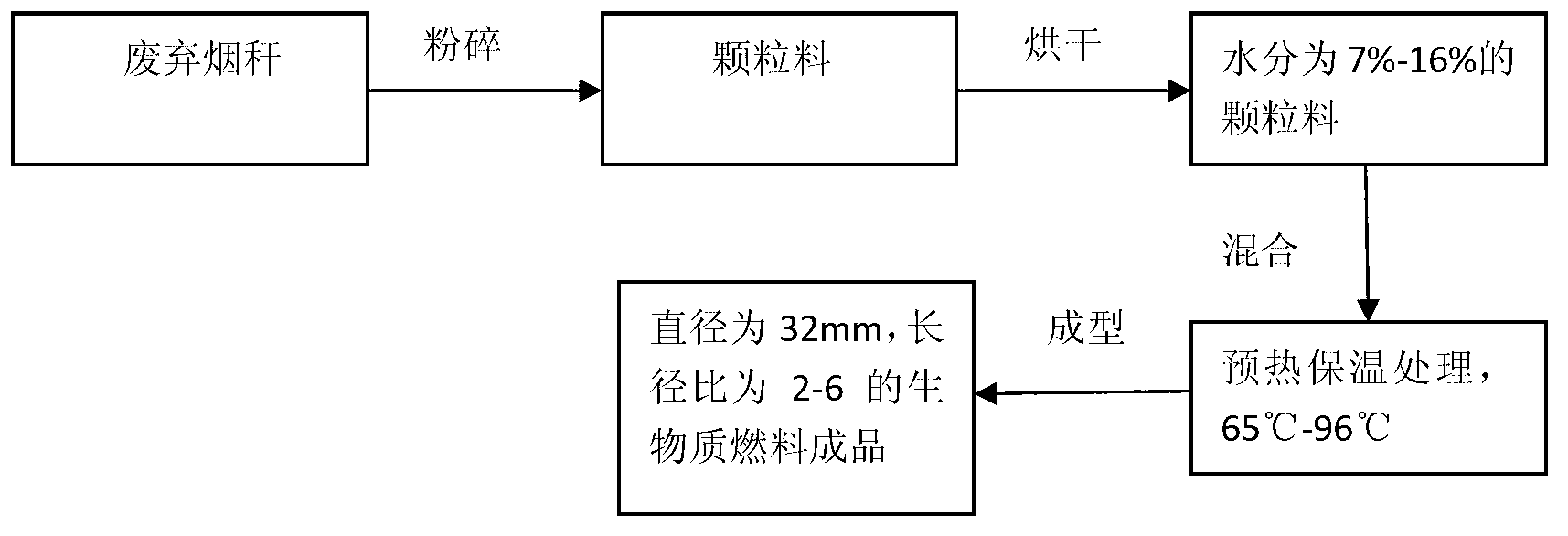

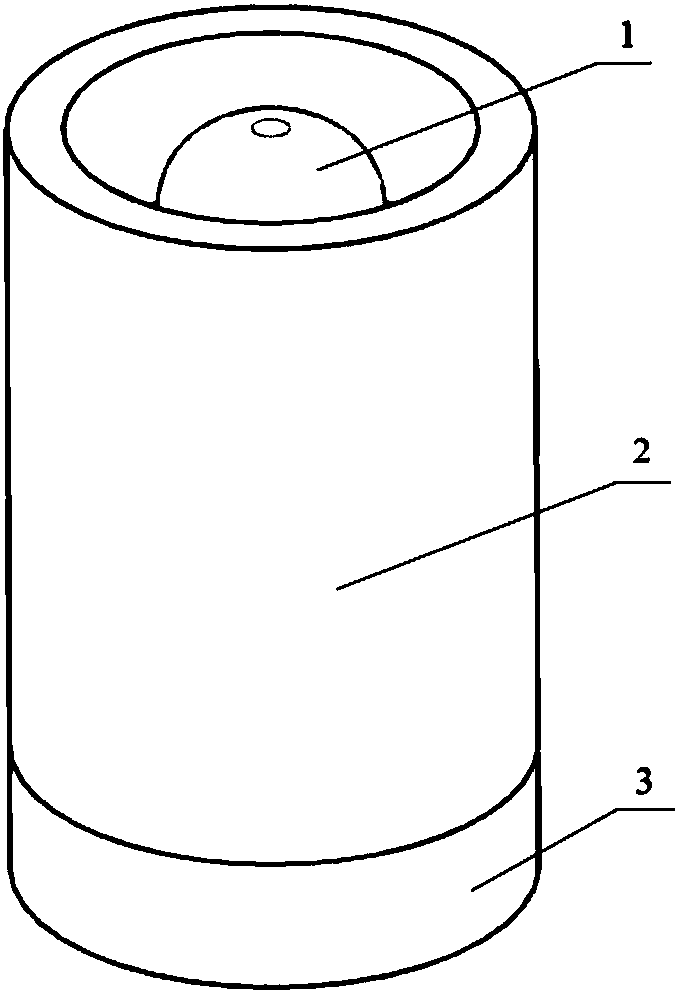

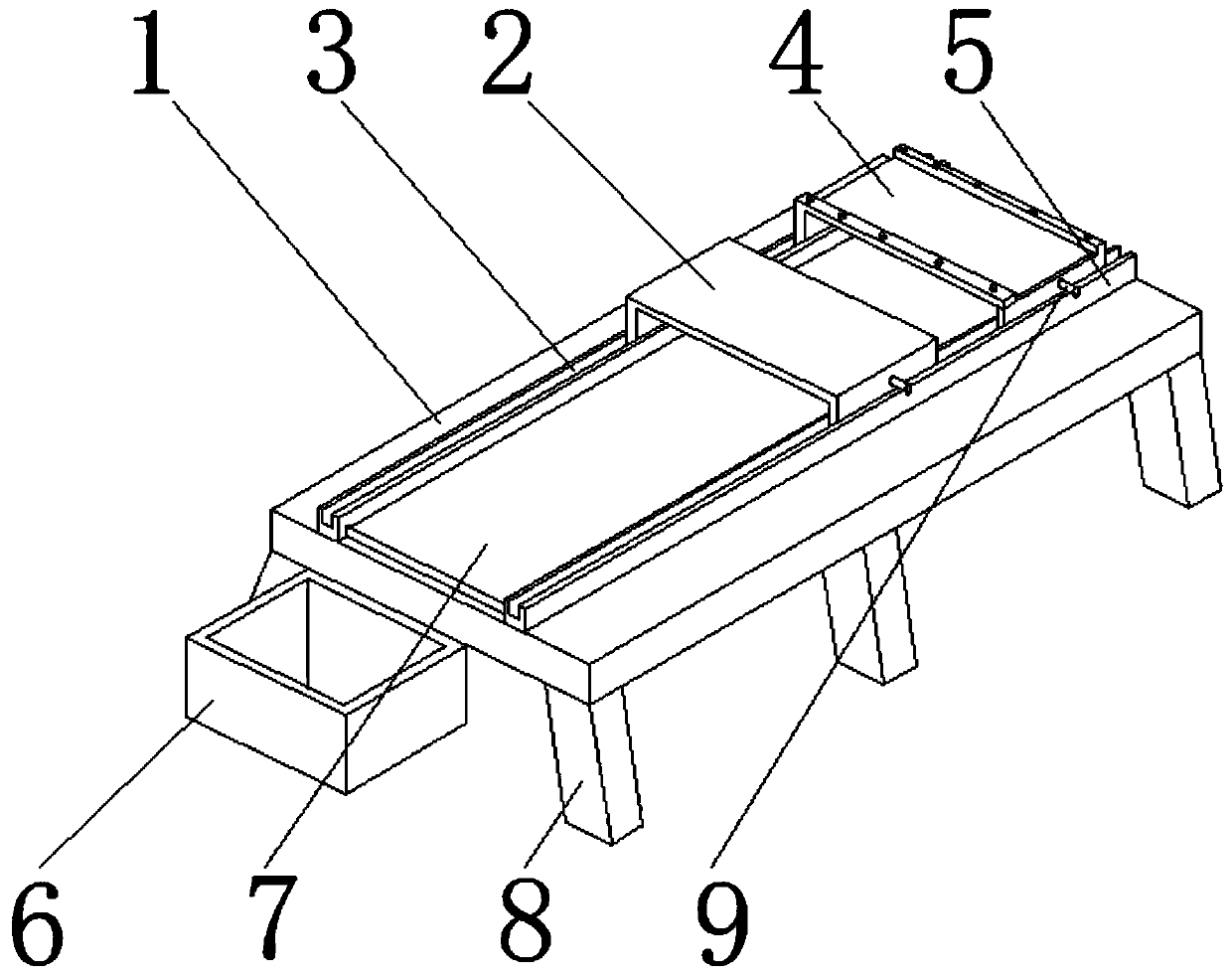

Method for preparing high-density biomass fuel for roasting tobacco by tobacco stalks

The invention relates to a method for preparing a high-density biomass fuel for roasting tobacco by tobacco stalks. The method comprises the following steps: smashing, waste tobacco (tobacco stalks, tobacco stems and tobacco leaves) used as a raw material, to obtain 1-2cm, 4-6cm and 8-10cm particle materials; drying the particle materials in a hot blast drying furnace till the water content is 7-16%; feeding dried and mixed particle materials to a stirring heater to heat; and pressing and forming by a forming device, namely a flat-die machine to obtain a product, wherein the product obtained is a solid cylinder with the diameter which is 32mm, the density which is 1.4g / cm<3>, 1.4-1.3g / cm<3> and 1.2-1.3g / cm<3>, and the length-diameter ratio l:d which is 2-6. No chemical additives are added in the preparation process. The density of the biomass fuel prepared by the invention can reach 1.2-1.4g / cm<3>, so that the biomass fuel can meet heat demands for roasting the tobacco leaves in different stages. The capacity for providing heat is better than that of fire coal, and heat provided by unit time is 4 times that of the fire coal.

Owner:云南省烟草公司大理州公司

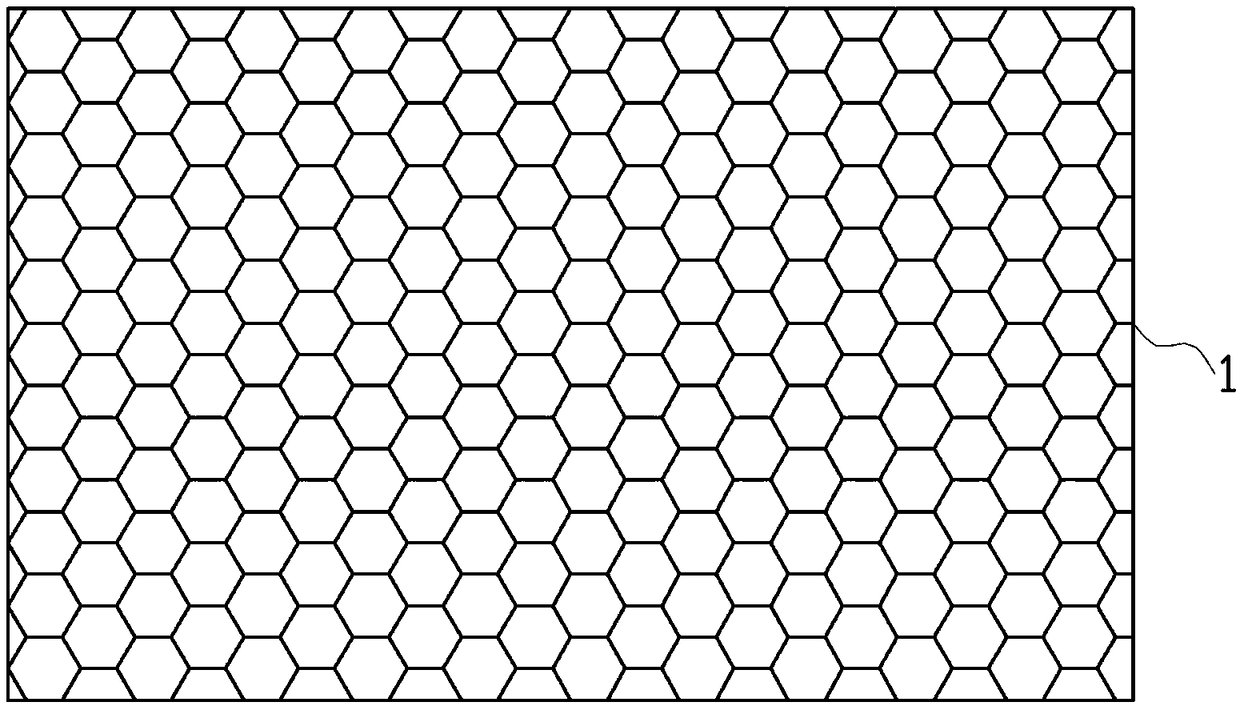

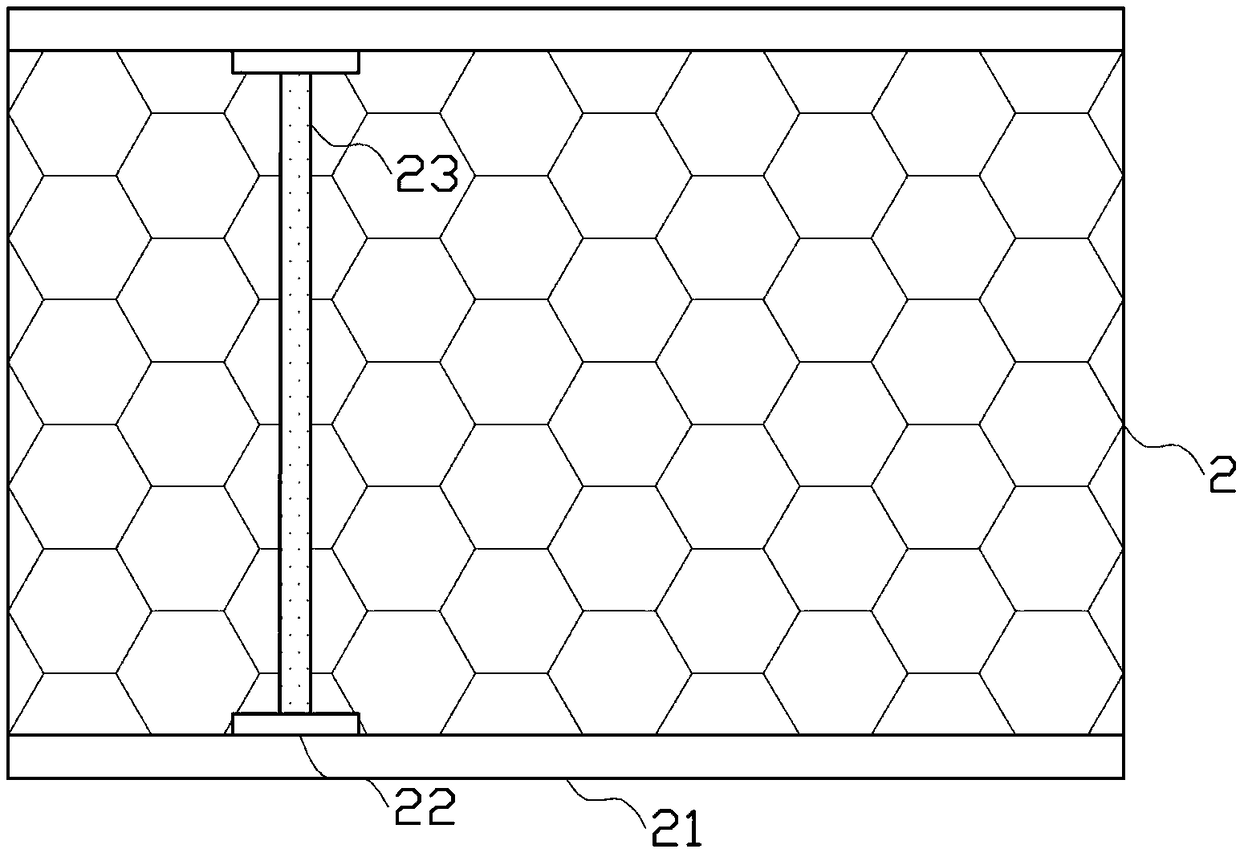

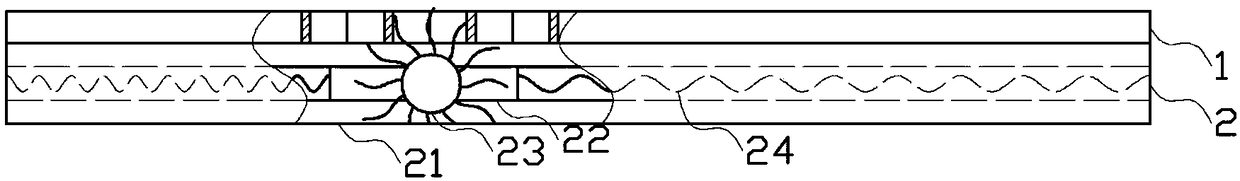

Layered automatic cleaning automobile floor mats

The invention provides a layered automatic cleaning automobile floor mat, which comprises a tread layer, an adsorption layer and a cleaning module. A surface of that tread layer is provide with a hollow structure; The adsorption layer is arranged under the treading layer, and the upper surface of the adsorption layer is provided with spaced grooves; Symmetrical sliding rails are arranged on both sides of the adsorption layer, symmetrical sliding grooves are arranged on opposite faces of the sliding rails, sliding blocks are arranged in the sliding grooves, and tension springs are arranged between the two sides of the sliding blocks and the end faces of the sliding rails; A slide bar is connected between the sliding blocks; The sliding rod is provided with bristles, and the upper end of thebristles is in contact with the treading layer; The layered automatic cleaning automobile floor mat is a device which utilizes the inertia of the automobile to sweep the dust and accumulated water adhered to the top layer of the automobile foot cushion into the storage space of the bottom layer, and can clean the soles of the feet of passengers at the same time.

Owner:张宜民

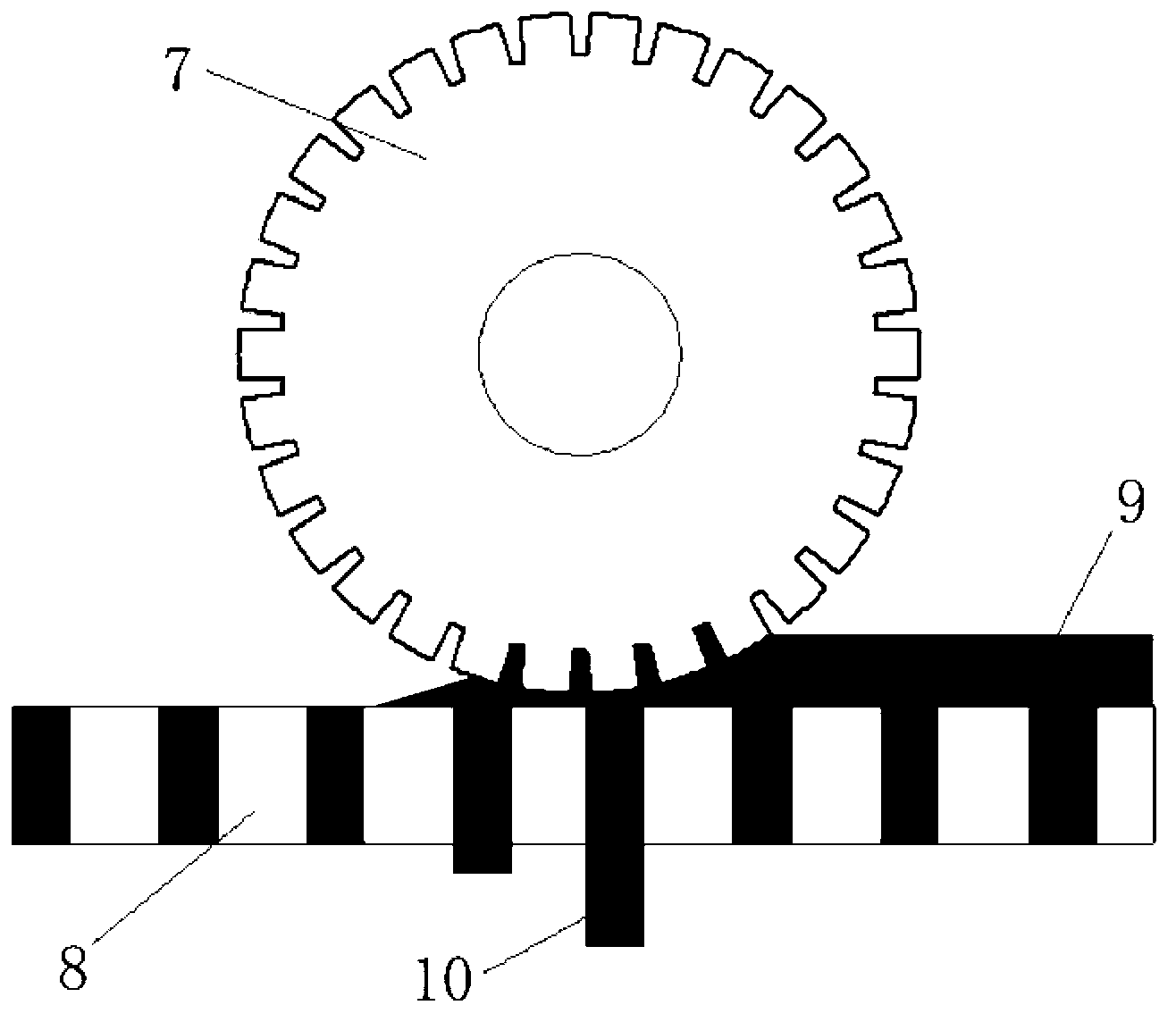

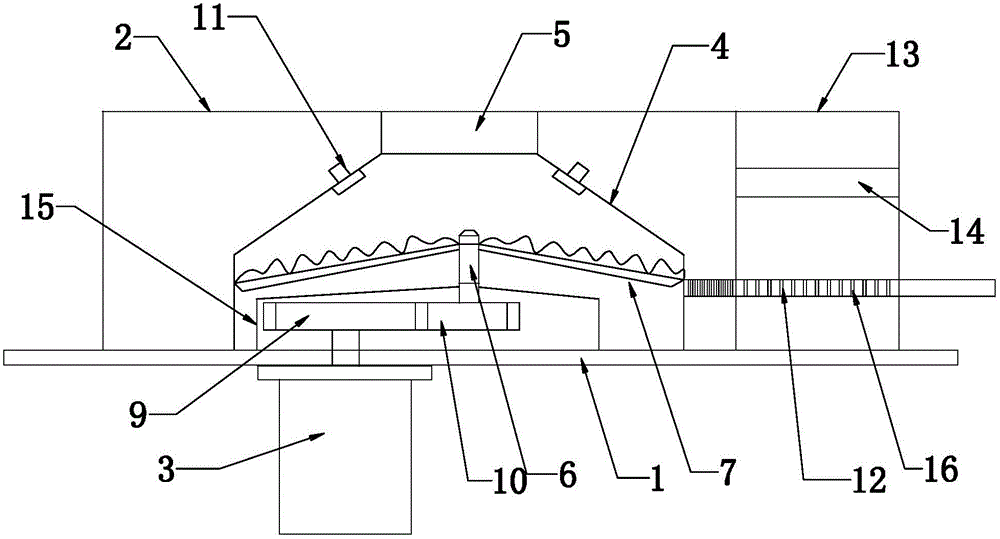

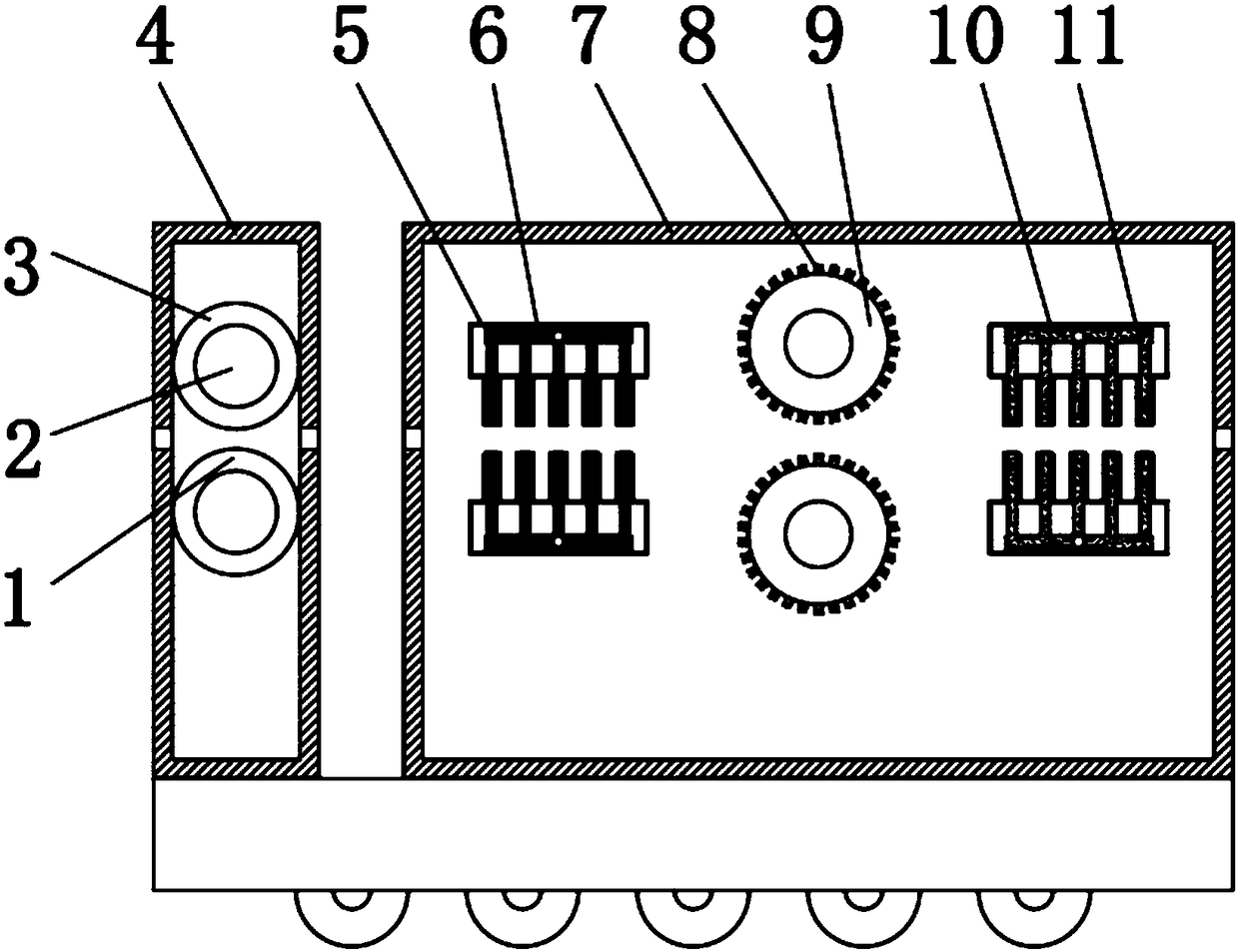

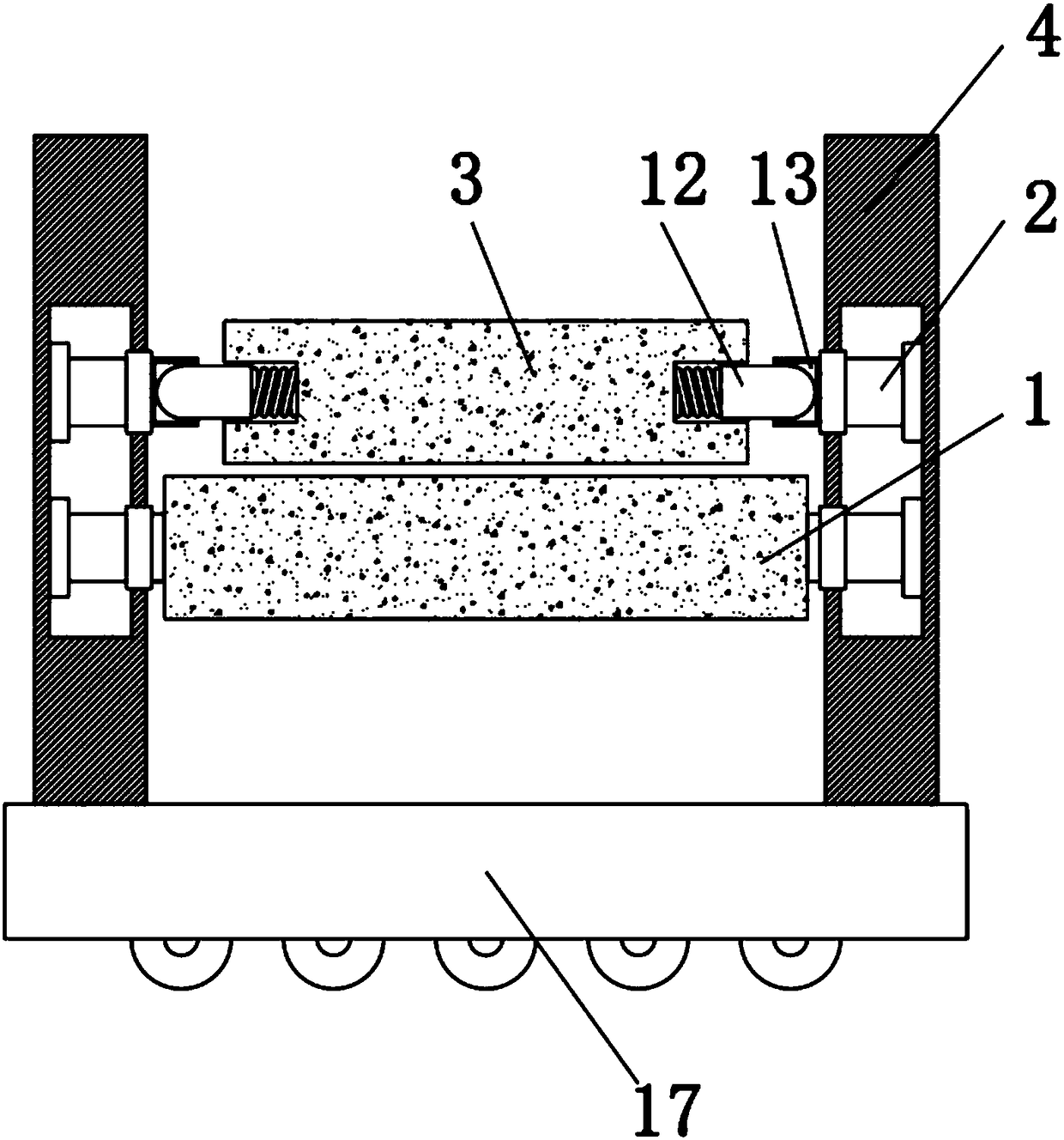

Tile rubbing and shuffling device of mahjong machine

The invention discloses a tile rubbing and shuffling device of a mahjong machine. The tile rubbing and shuffling device comprises a rack, a casing and a drive motor, wherein a tile rubbing and shuffling bin of a cylinder structure is arranged in the casing, a tile inlet is formed in the top part of the tile rubbing and shuffling bin, a rotating shaft is arranged on the tile rubbing and shuffling bin, a rotating disc provided with bulges and pits is mounted on the rotating shaft, and the periphery of the rotating disc is covered with a rotating disc covering surface; an output shaft of the drive motor stretches into the tile rubbing and shuffling bin, spray nozzles are distributed on all the top face and the side faces of the tile rubbing and shuffling bin, and a tile outlet is formed in the back side of the tile rubbing and shuffling bin; a drying chamber is arranged at the back of the casing, and a conveying rail and a drying device are arranged in the drying chamber. After the structure is adopted, mahjong tiles are cleaned by the spraying nozzles when entering the tile rubbing and shuffling bin, and can directly enter the drying chamber for drying after cleaning is completed, the cylindrical structure enables the mahjong tiles to be uniformly dispersed, and the mahjong tiles are directly dried after cleaned by the spray nozzles, so that the mahjong tiles are thoroughly cleaned, and prevented from being polluted again; the cleaning effect is good.

Owner:JIANGSU DANBOM MECHANICAL & ELECTRICAL

Self-service clothes washing method, server, user side, clothes storage cabinet and handheld terminal

PendingCN112991630AImprove user experienceImprove customer satisfactionCoin-freed apparatus detailsApparatus for meter-controlled dispensingLaundryService worker

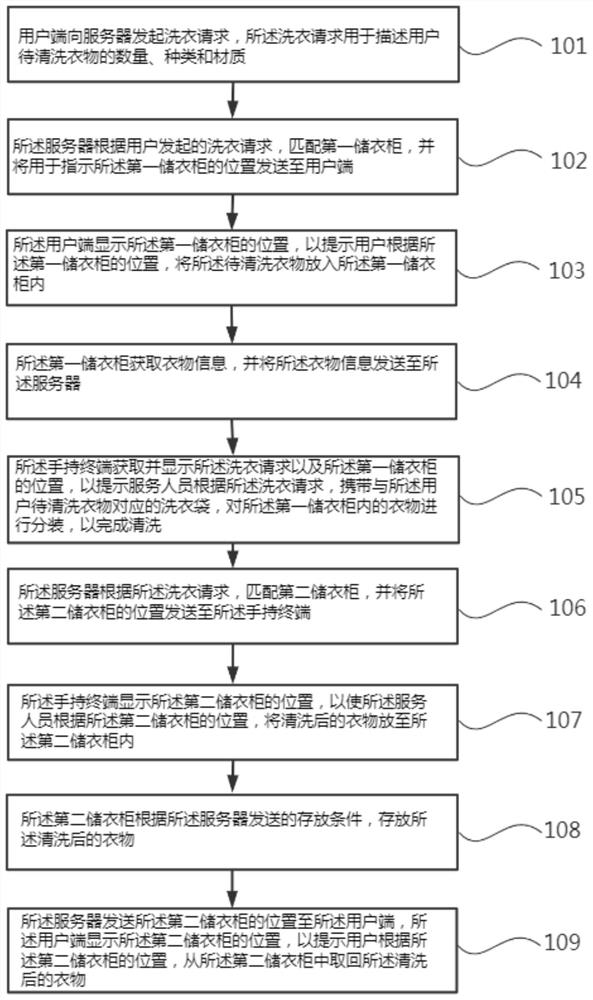

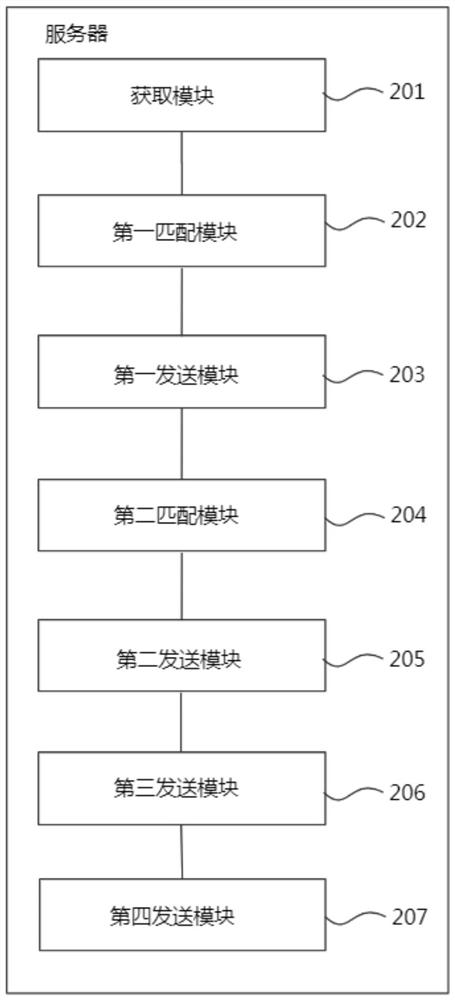

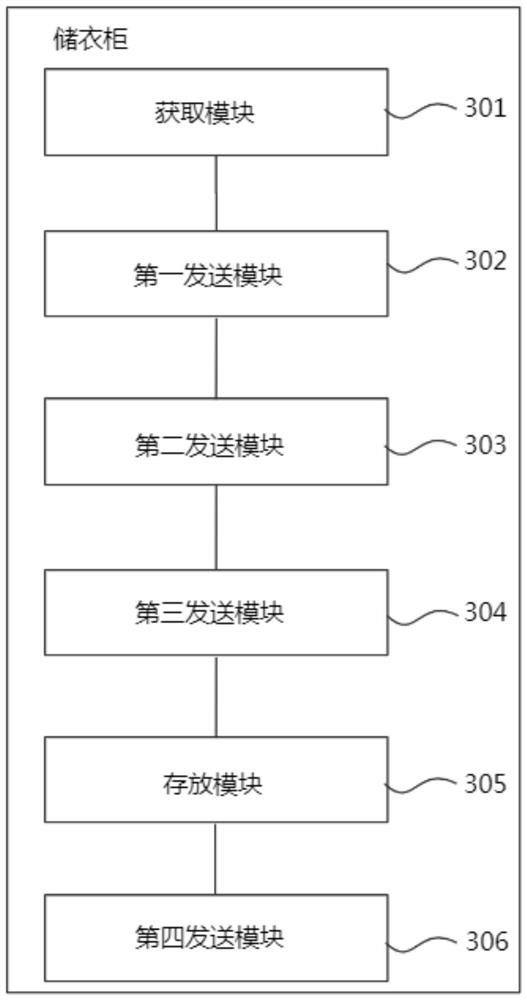

The invention relates to a self-service clothes washing method, a server, a user side, a clothes storage cabinet and a handheld terminal. The self-service clothes washing method comprises the steps that the server receives a clothes washing request initiated by a user through the user side; according to the clothes washing request, a first clothes storage cabinet is matched, and the position of the first clothes storage cabinet is sent to the user side; the clothes washing request is sent to a handheld terminal of a service staff, so that the service staff carries a clothes washing bag corresponding to the clothes to be washed of the user according to the clothes washing request, the clothes in the first clothes storage cabinet are subpackaged, and washing is completed; according to the clothes washing request, a second clothes storage cabinet is matched, and the position of the second clothes storage cabinet is sent to the service staff so that the service staff places the washed clothes in the second clothes storage cabinet; the clothes storage condition is sent to the second clothes storage cabinet so that the second clothes storage cabinet stores the washed clothes according to the storage condition; the position of the second clothes storage cabinet is sent to the user side so that the user takes back the washed clothes from the second clothes storage cabinet. The method has the effect that self-service clothes washing is simpler and more convenient.

Owner:杭州余杭兴隆绸厂

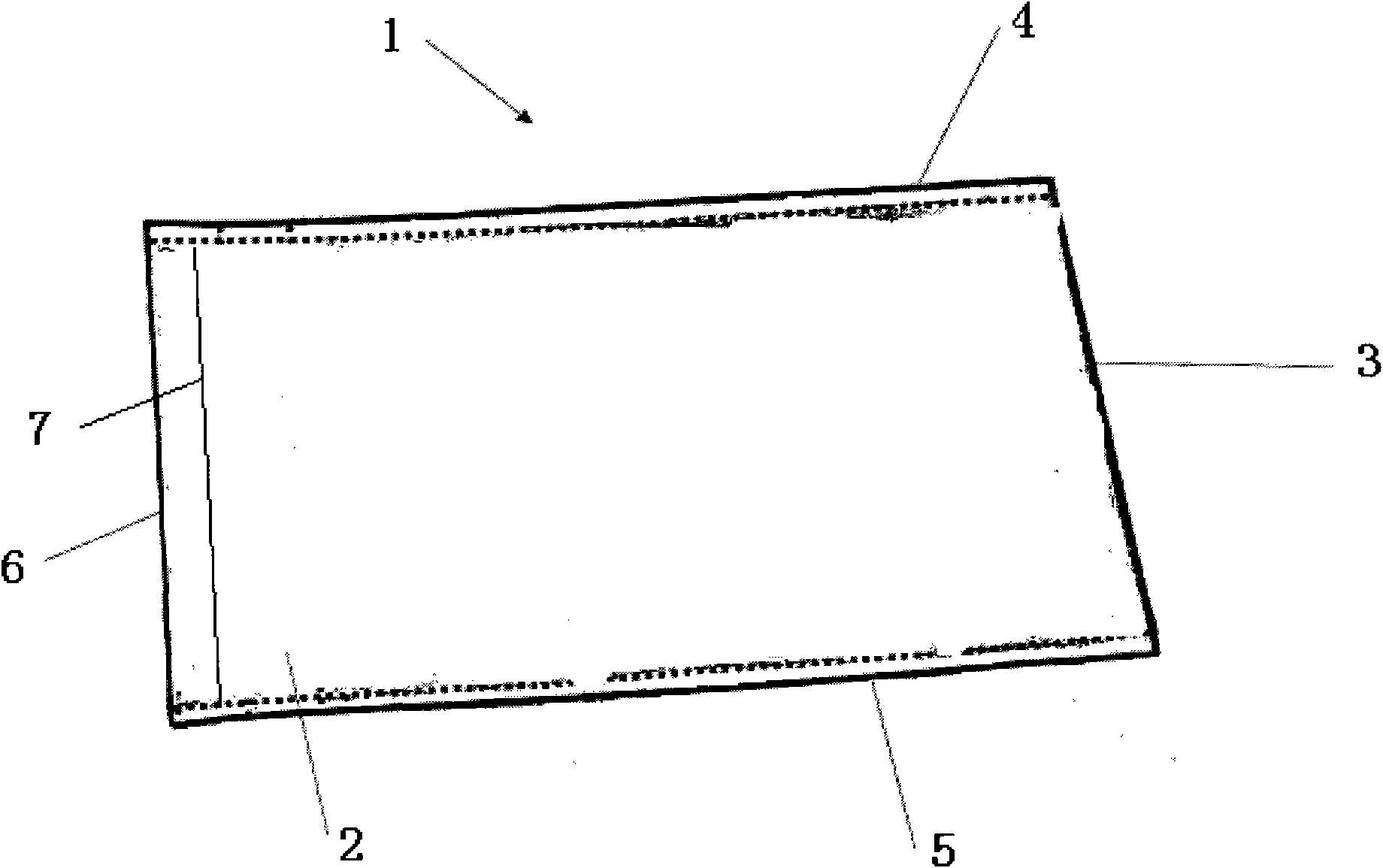

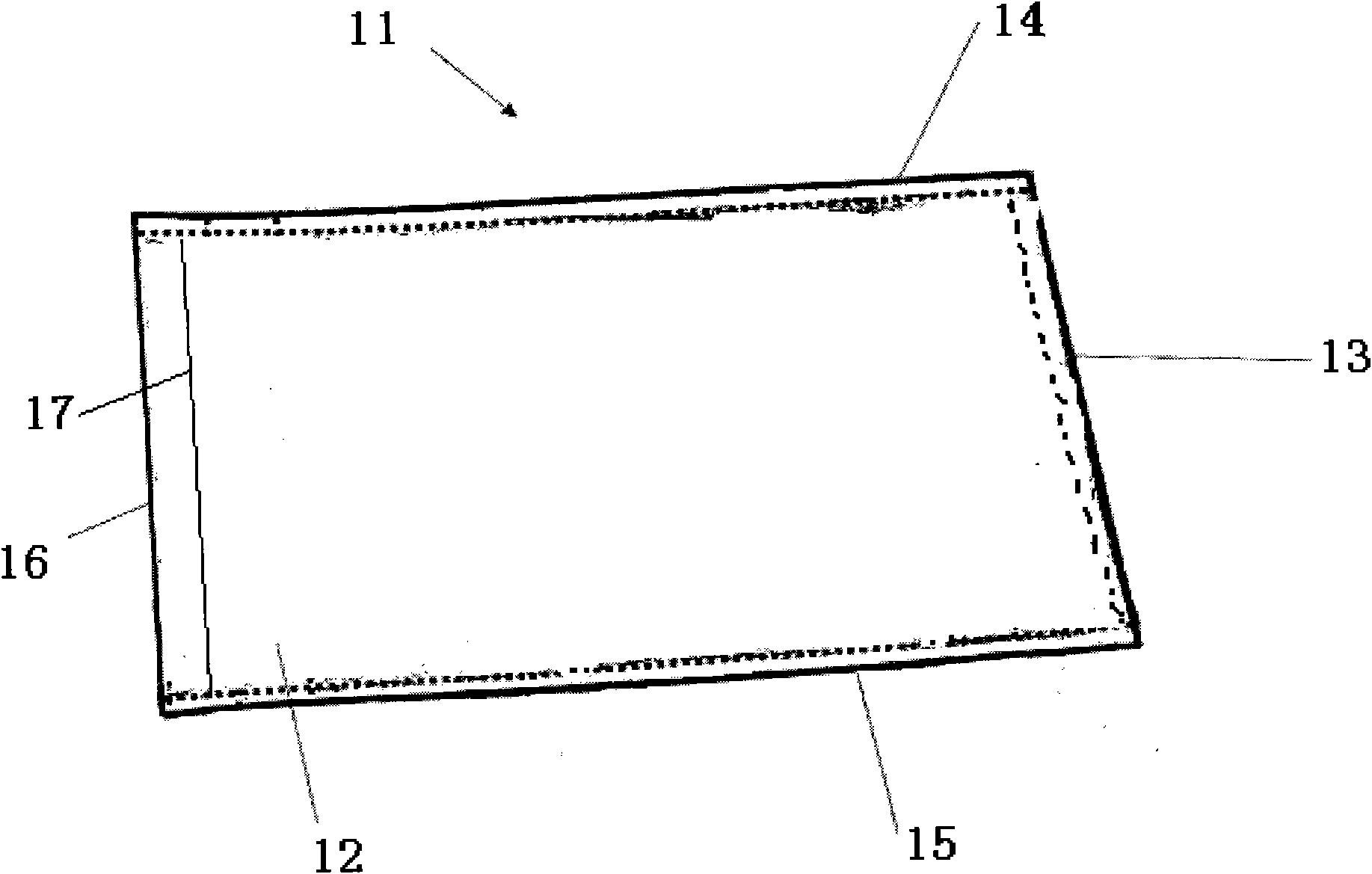

Medical apparatus packing bag

The invention relates to a medical apparatus packing bag which comprises a first surface, a second surface and an opening and is characterized in that: the first surface and the second surface are formed by laminating a polyethylene layer or polyester layer and a polyamide layer. As the medical apparatus packing bag is compounded with the polyamide layer or polyester layer, when the medical apparatus is contained, the problem that the sterilized medical apparatus is polluted again as the medical apparatus packing bag is pricked by sharp medical apparatus such as medical shears can be avoided.

Owner:焦旭冉 +1

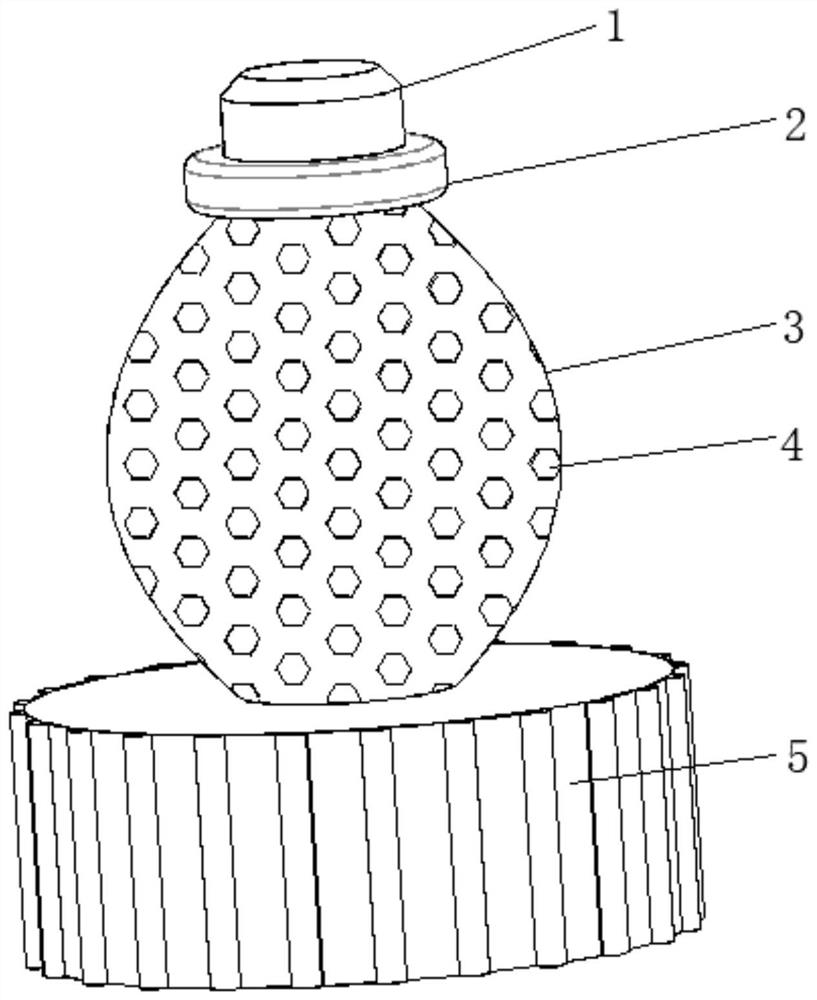

Camera air blower

InactiveCN112718701ADoes not affect ventilation ratePlay a blocking roleCombination devicesElectrostatic separationStructural engineeringAir blower

The invention provides a camera air blower, and relates to the field of camera auxiliary equipment. The camera air blower comprises a fixing head, a mounting ring, a rubber layer, anti-skid pads and a cleaning mechanism, wherein the fixing head is fixedly connected with the inner wall of the mounting ring; the rubber layer is arranged on the inner wall of the mounting ring; the anti-skid pads are evenly arranged on the outer wall of the rubber layer; the cleaning mechanism is arranged at the bottom end of the rubber layer; an air guide pipe is arranged on the outer wall of one side of the mounting ring; air holes are formed in the outer wall of the air guide pipe; a buffer mechanism is arranged between the air guide pipe and the rubber layer; the buffer mechanism comprises a telescopic spring, a piston and a sliding barrel; the outer wall of the air guide pipe at one end of the sliding barrel is fixedly connected; the piston is movably connected with the inner wall of the sliding barrel; the space between the piston and the sliding barrel is filled with buffer gas; and one end of the telescopic spring is connected with the piston. According to the camera air blower, external dust can be prevented from entering the air blower, a lens is prevented from being secondarily polluted, the ventilation speed of the air blower is not influenced, and the camera air blower is convenient to use.

Owner:闫雅

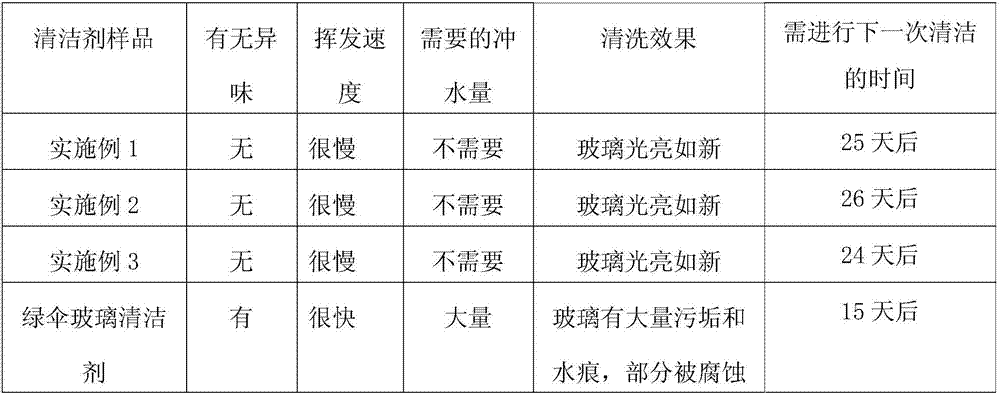

Vehicle window glass detergent and production technology thereof

InactiveCN107043659AReduce surface tensionExcellent decontaminationInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlkanePolyethylene glycol

The invention provides a vehicle window glass detergent and a production technology thereof, and relates to the technical field of detergents. The vehicle window glass detergent comprises sodium alkyl benzene sulfonate, secondary alkane sulfonate, alkylphenol polyoxyethylene ether, lauroyl diethanolamide, glucosyl dimethyl ester, sodium alginate, ethylenediamine tetraacetic acid, diethylenetriamine pentacarboxylic acid, carboxymethylcellulose sodium, polyethylene glycol, aminobenzoic acid, modified kaolin, a detergent and deionized water. The c vehicle window glass detergent has the advantages of remarkable effect, simplicity in preparation, wide application range, no peculiar smell, harmlessness to human bodies, and saving of a lot of manpower and material resources due to realization of bright glass only through uniformly coat the surface of glass with the detergent in use and wipe-drying with a clean cotton cloth without clear water flushing, and is worth promoting production.

Owner:岑健

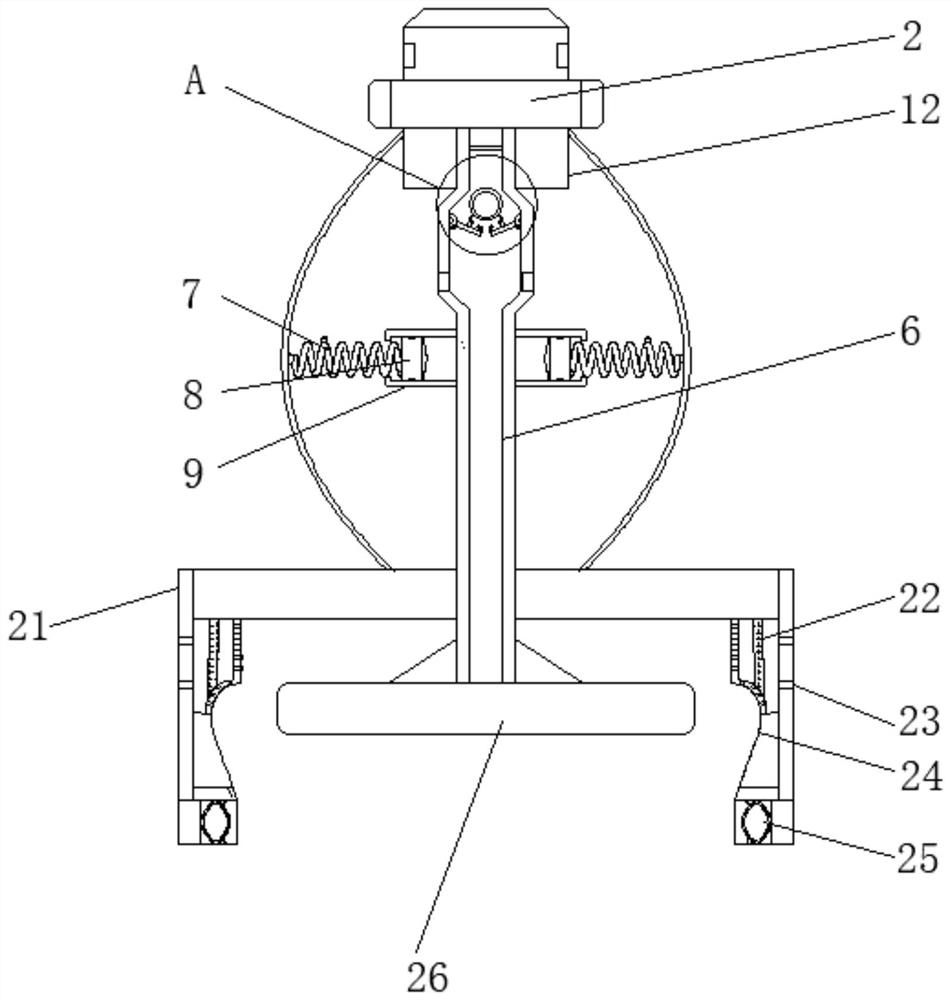

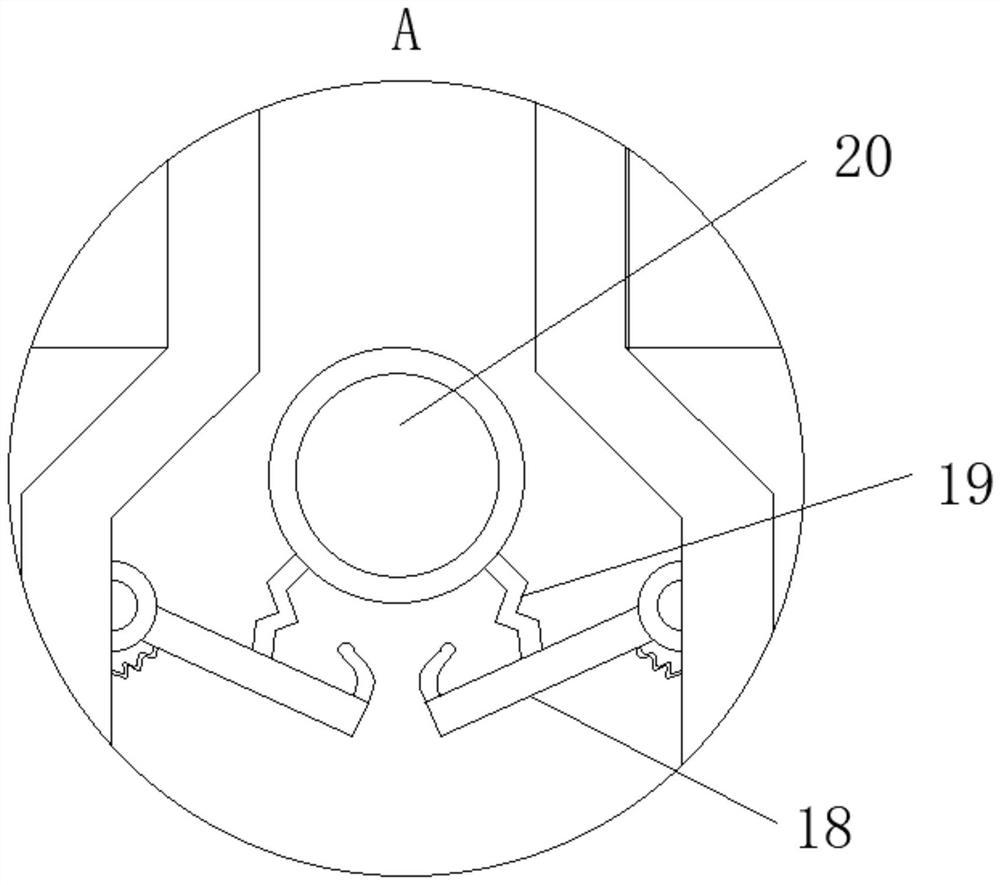

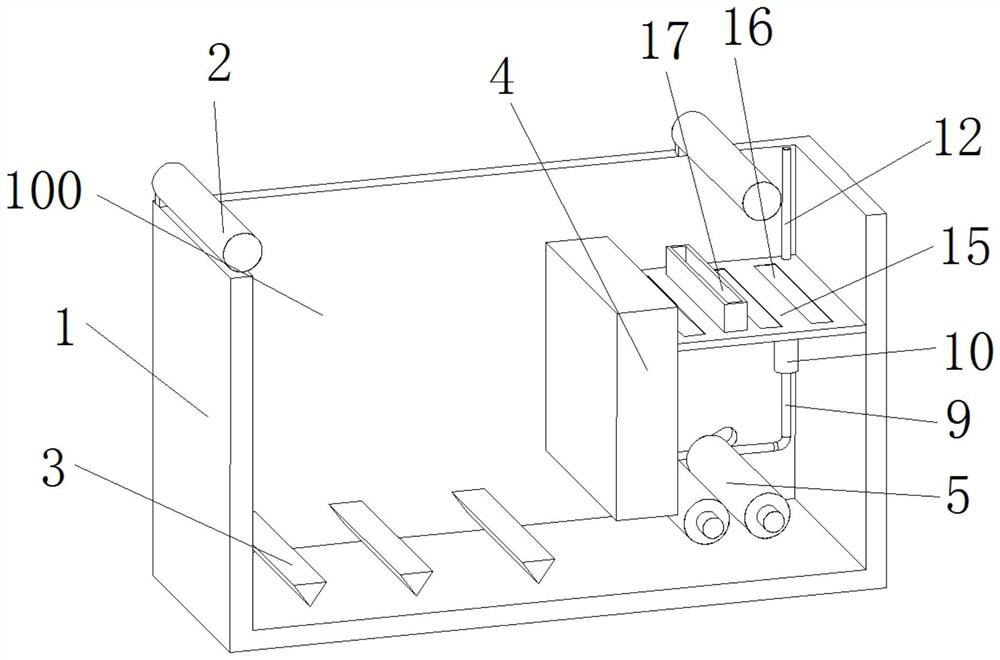

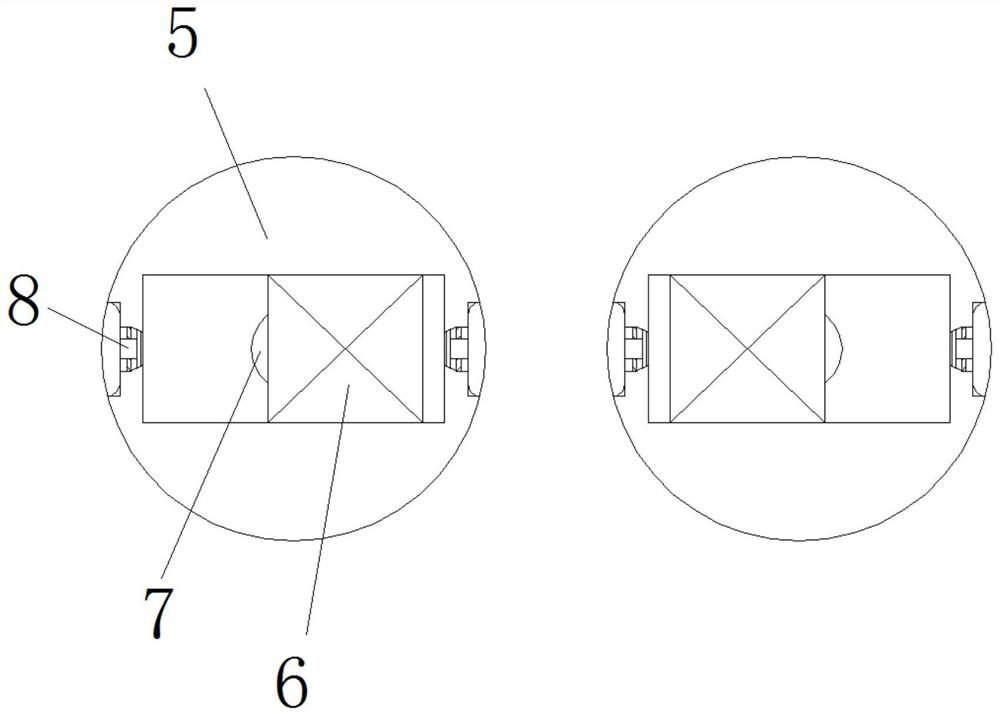

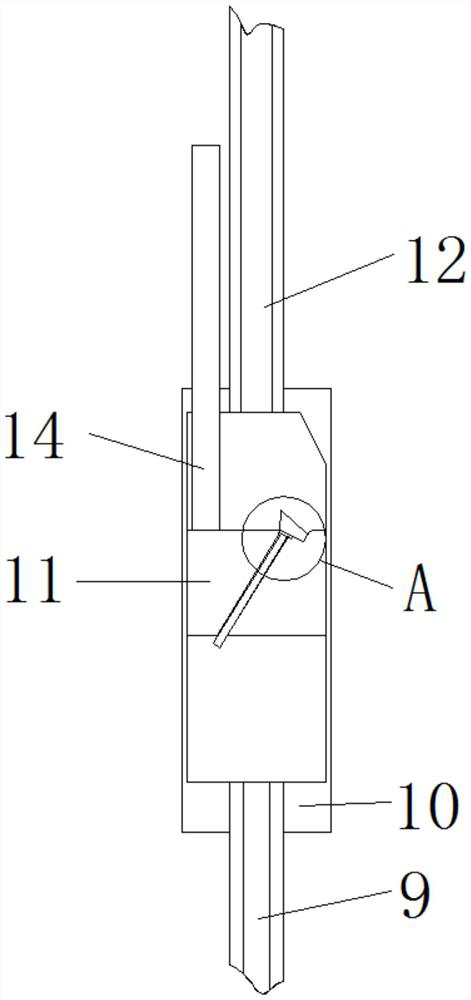

Surface sticky fluff removing device for garment production and processing

InactiveCN112359577AImprove cleanlinessAvoid re-contaminationMechanical cleaningPressure cleaningWater pipeStructural engineering

The invention provides a surface sticky fluff removing device for garment production and processing. Ejector rods are arranged on the inner surfaces of fan-shaped plates, the ejector rods penetrate through the interiors of side bases, movable bases are arranged on the upper surfaces of the ejector rods, connecting rods are fixedly installed on the outer sides of the movable bases, push plates arefixedly installed at the bottoms of the connecting rods, flexible bags are arranged on the outer surfaces of the push plates, and the outer sides of the flexible bags are fixedly connected with watertanks through water pipes. When the top ends of the fan-shaped plates swing to the outer side, after the fan-shaped plates are separated from inclined blocks on the surfaces of the ejector rods, the ejector rods are driven to move downwards and meanwhile make contact with rollers on the surface of the movable bases, the movable bases and the connecting rods are driven to move inwards, the push plates at the bottoms of the connecting rods stretch the flexible bags, and water in the water tanks makes contact with a garment fabric through spray heads, so that a garment is subjected to atomizationand dust removal treatment in the fluff removing process, and meanwhile the situation that fluff flies around and is inhaled by workers in the clothing fluff sticking process, resulting in harm to the bodies of the workers is avoided.

Owner:东阳梦凡特时装有限公司

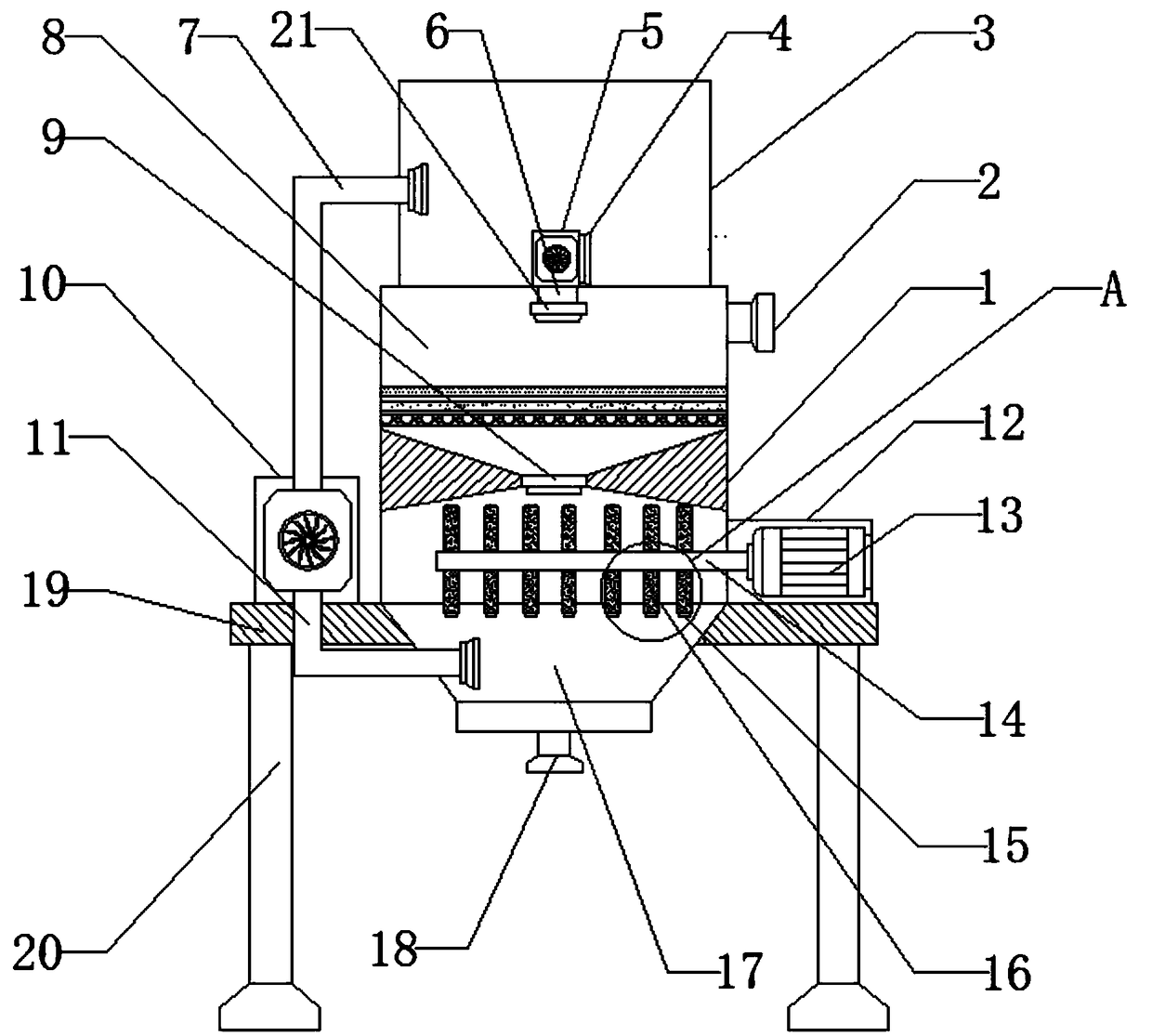

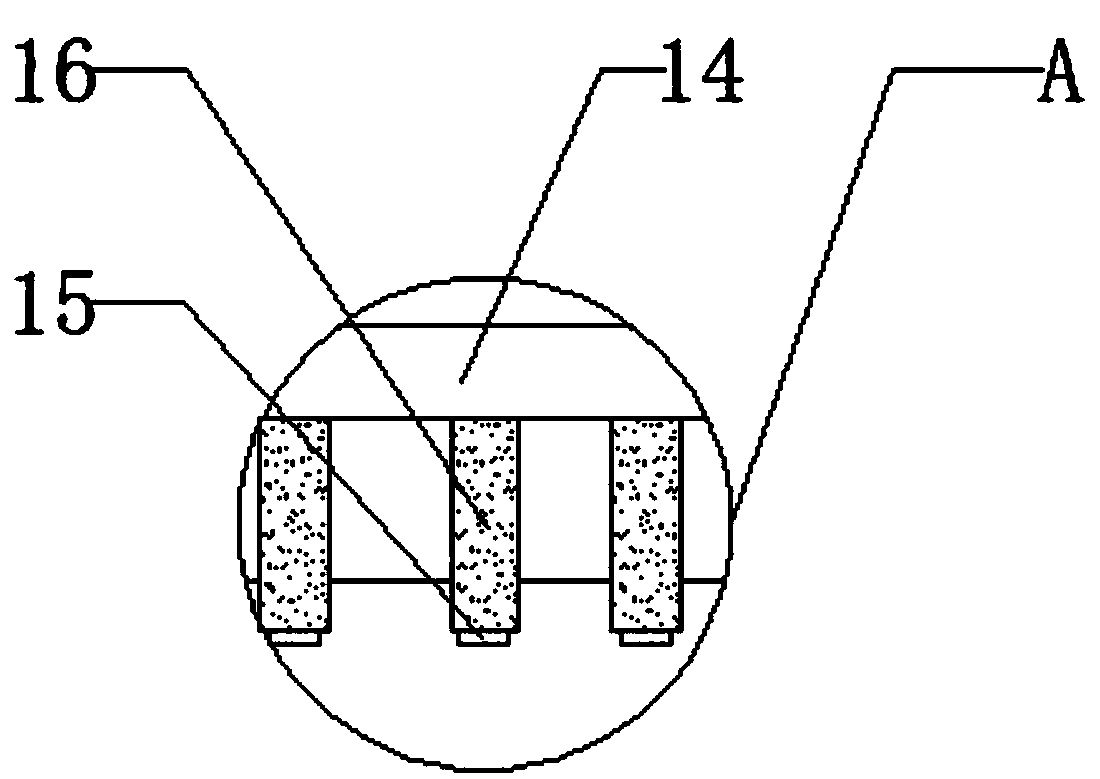

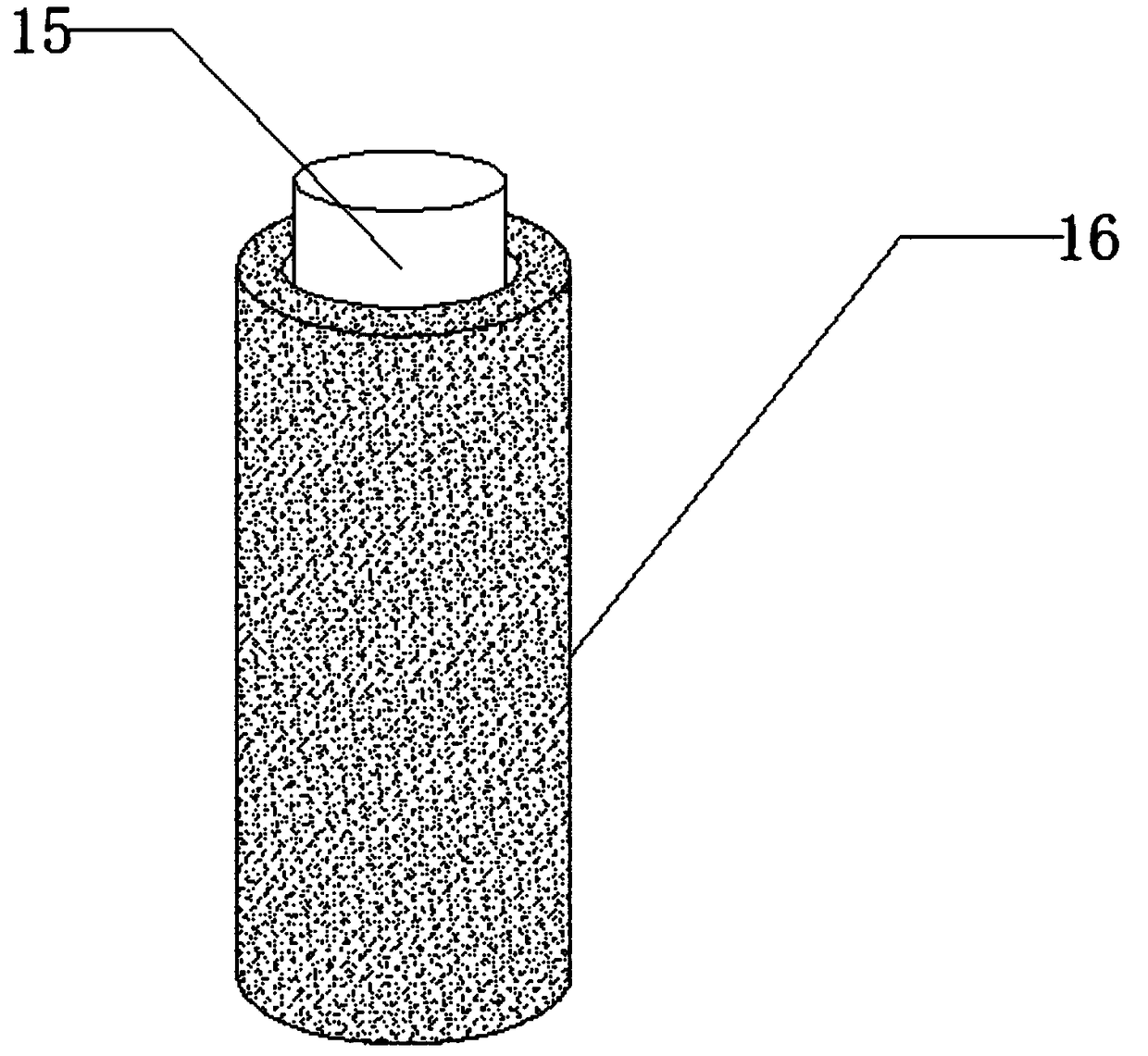

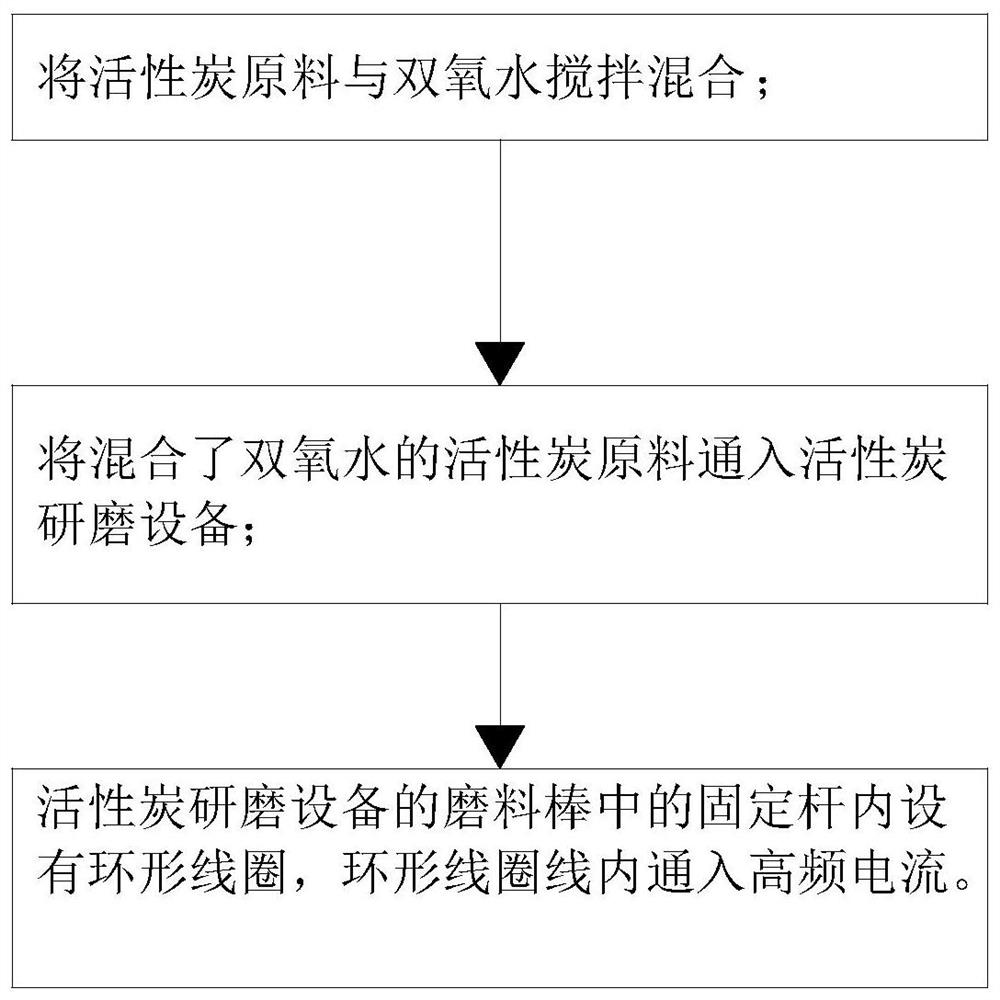

Activated carbon grinding process

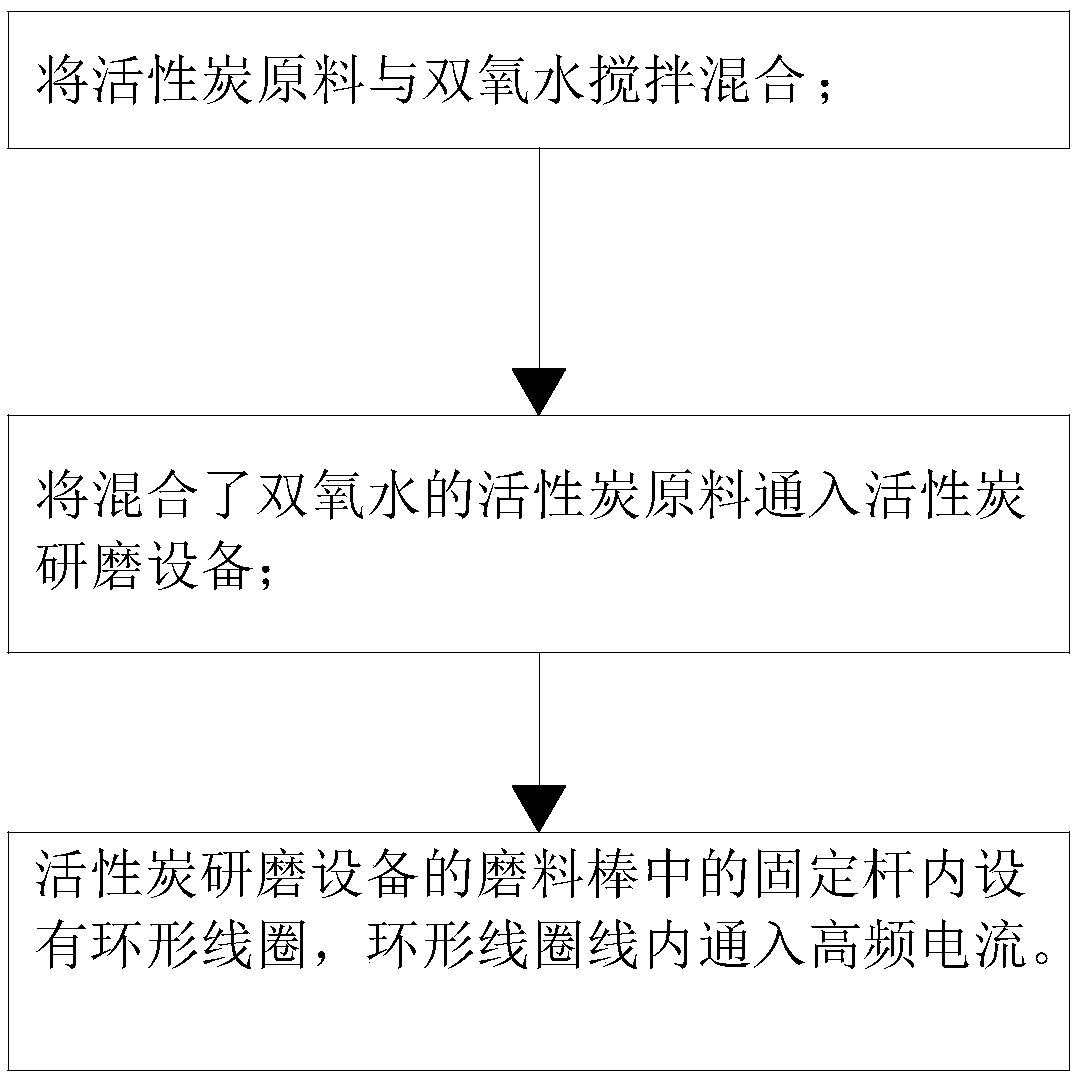

ActiveCN109351419AQuality improvementGuaranteed drynessGrain treatmentsChemicalsActivated carbonPower flow

The present invention belongs to the technical field of activated carbon grinding, in particular to an activated carbon grinding process; the grinding process comprises the following steps of: mixingan activated carbon raw material with hydrogen peroxide; introducing the activated carbon raw material mixed with the hydrogen peroxide into activated carbon grinding equipment; arranging an annular coil within a fixed rod in an abrasive rod of the activated carbon grinding equipment, and introducing high-frequency current into an annular coil wire. The activated carbon grinding process of the present invention has the characteristics that hydrogen peroxide is utilized to kill bacteria on the surface of the activated carbon raw material so as to improve the quality of the produced activated carbon; moisture in the activated carbon raw material is evaporated through temperature generated by introducing high-frequency current into the annular coil wire so that the produced activated carbon is ensured in dryness to facilitate the use of the activated carbon; the use of the ground activated carbon is not affected due to bonding so as to improve the using effect; and the moisture in the activated carbon raw material is more conducive to grinding after being evaporated, thereby improving the grinding quality.

Owner:宁夏浦士达环保科技有限公司

Canned fruit deep processing cooling device

InactiveCN112120074AImprove cooling effectAvoid re-contaminationSpecific water treatment objectivesTreatment involving filtrationCanned fruitWastewater

The invention provides a canned fruit deep processing cooling device, and relates to the technical field of food processing. The canned fruit deep processing cooling device comprises a lower box body,refrigeration equipment, a water tank and a water pump are arranged on the inner bottom face of the lower box body, the refrigeration equipment is arranged on the front side of the water tank, the water pump is located on the left side of the water tank, a first connecting pipe is arranged between the water tank and the water pump, a second connecting pipe is arranged at a water outlet of the water pump, a first electromagnetic valve is arranged in the middle of the second connecting pipe, a horizontal pipeline is arranged on the upper inner wall of the lower box body, and the end, away fromthe water pump, of the second connecting pipe is connected with the horizontal pipeline. Canned bottles are cooled and conveyed at the same time through a cooling channel provided with a spray head, compared with a conveying device, the device is safer, waste water is recycled after cooling, the waste water is reused after being filtered through a filter screen and sterilized and disinfected through a silver screen plate, the canned bottles are put in a canned bottle storage rack in order under the action of a sliding way and a vibrator, and the device is very convenient to use.

Owner:砀山县虹桥食品有限公司

Water quality monitoring water supply device

InactiveCN109030102AStir wellAchieving stirringWithdrawing sample devicesPreparing sample for investigationWater qualitySewage

The invention discloses a water quality monitoring water supply device. The water quality monitoring water supply device comprises a device body, a water inlet pipe is arranged above one side of the device body in a penetrating mode, a water purification bin is connected to the top of the device body, and a first water pump is connected below the inside of the water purification bin. The water quality monitoring water supply device is further provided with the first water pump, a second water pump, the water purification bin and a nozzle at the same time. After sewage is purified, the second water pump can pump purified water in a purification pool through a water pumping pipe and deliver the water into the water purification bin for storage through a water delivery pipe. When the device needs to be cleaned, the first water pump can pump water in the water purification bin through a water pumping opening and deliver the water into the nozzle through a connecting pipe, the nozzle can spray the water out to wash and clean a grit chamber, the washed and cleaned water can enter a water purification pool through a water outlet valve and is discharged by an exhaust water pipe, and the function of cleaning of the device is achieved, so that the sewage is avoided to remain in the device to cause an error on the result of next water quality monitoring.

Owner:合肥睿致新科技有限公司

Finishing method capable of effectively reducing nylon dyeing difference

InactiveCN111996822ADoes not affect the feelEasy to operateLiquid/gas/vapor treatment of propelled fabricsDyeing processPolymer scienceAcid dye

The invention provides a finishing method capable of effectively reducing the nylon dyeing difference. According to the finishing method, oil is removed by an oil remover DM-1119N, an oil-removed fabric is dyed with a mixed working solution of a dye, a diluent and an acid dye leveling agent, and in the fabric dying process, reworking is carried out in the case of vat difference, cloth difference and color difference between left and right parts of the same piece of cloth. Through the combined process of oil removal and dyeing, dyeing difference of the nylon fabric in the dyeing process is prevented, and color tones, color dots and color spots occurring in the dyeing process of the nylon fabric are prevented.

Owner:DYMATIC CHEM

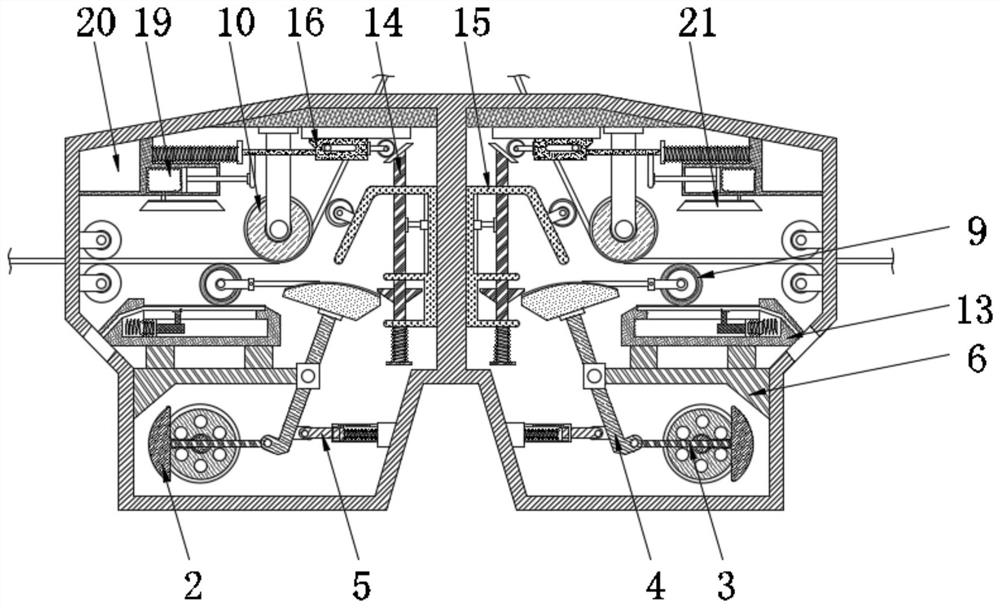

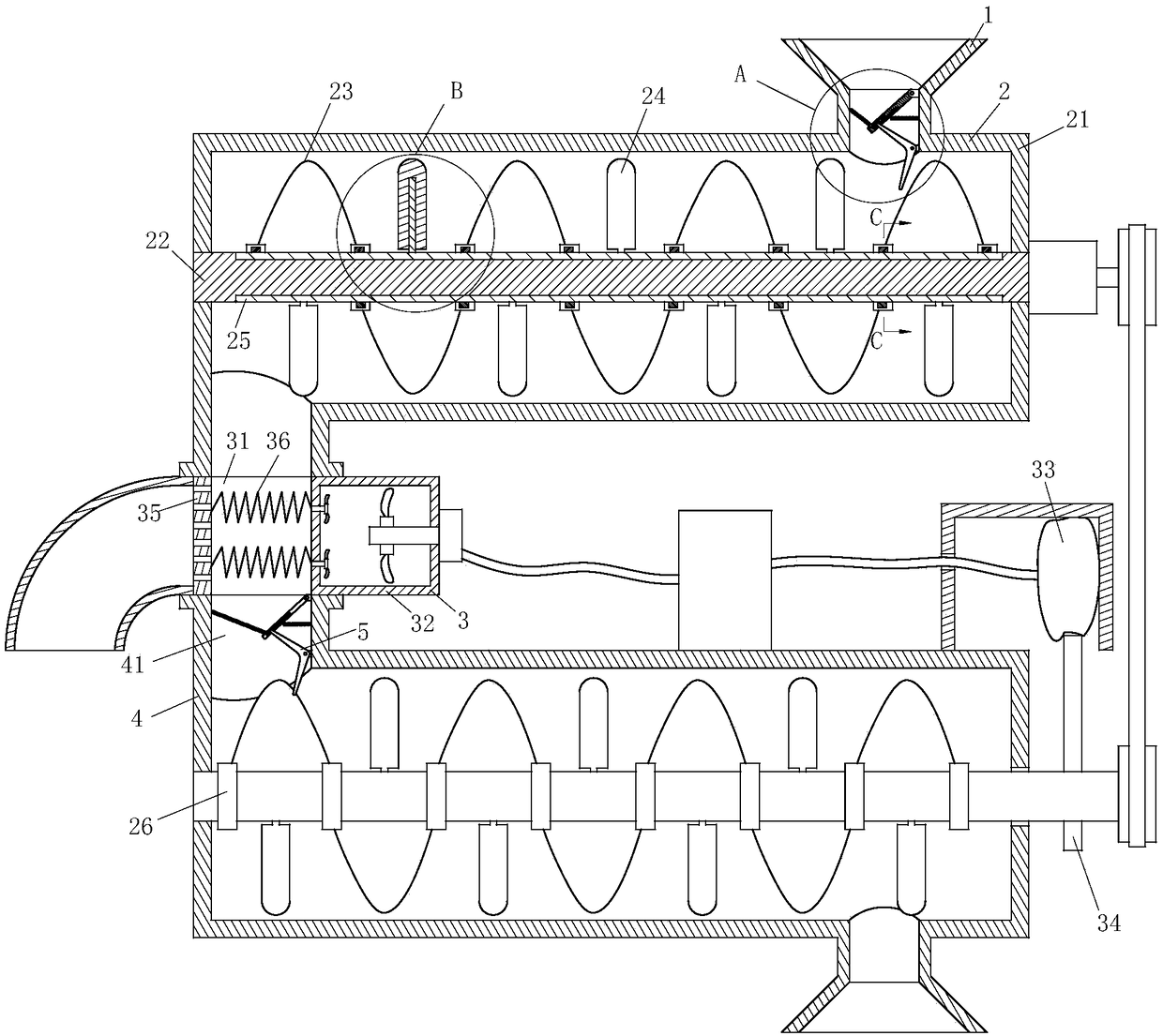

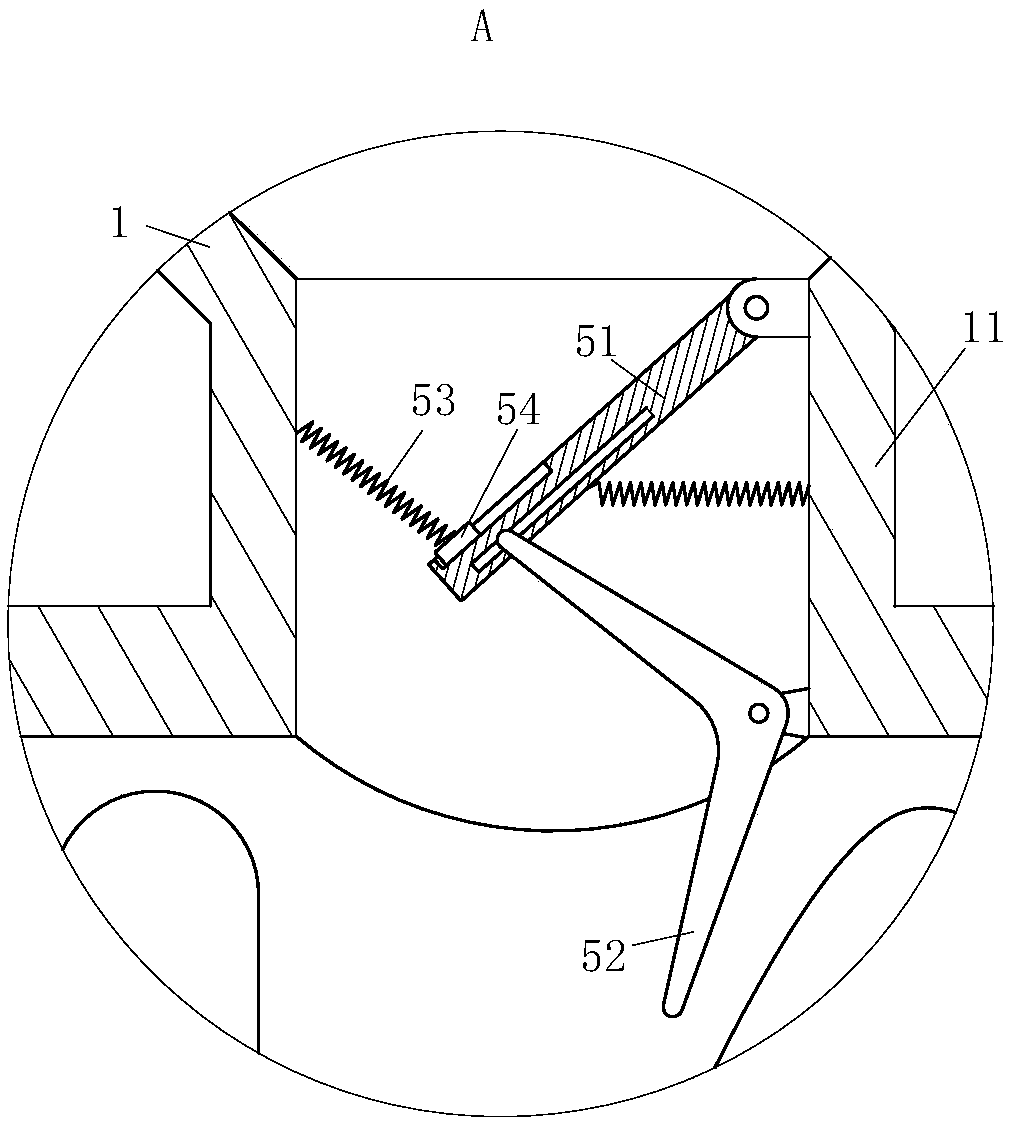

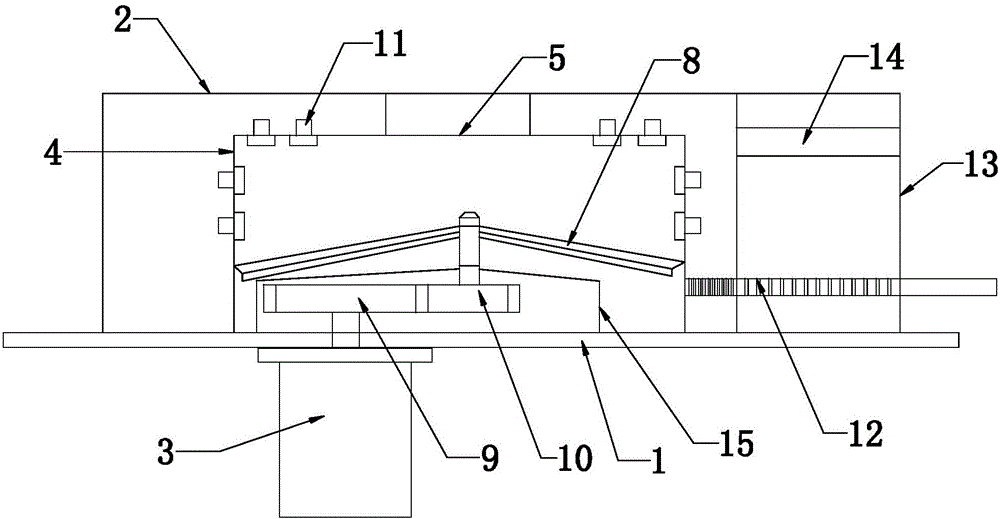

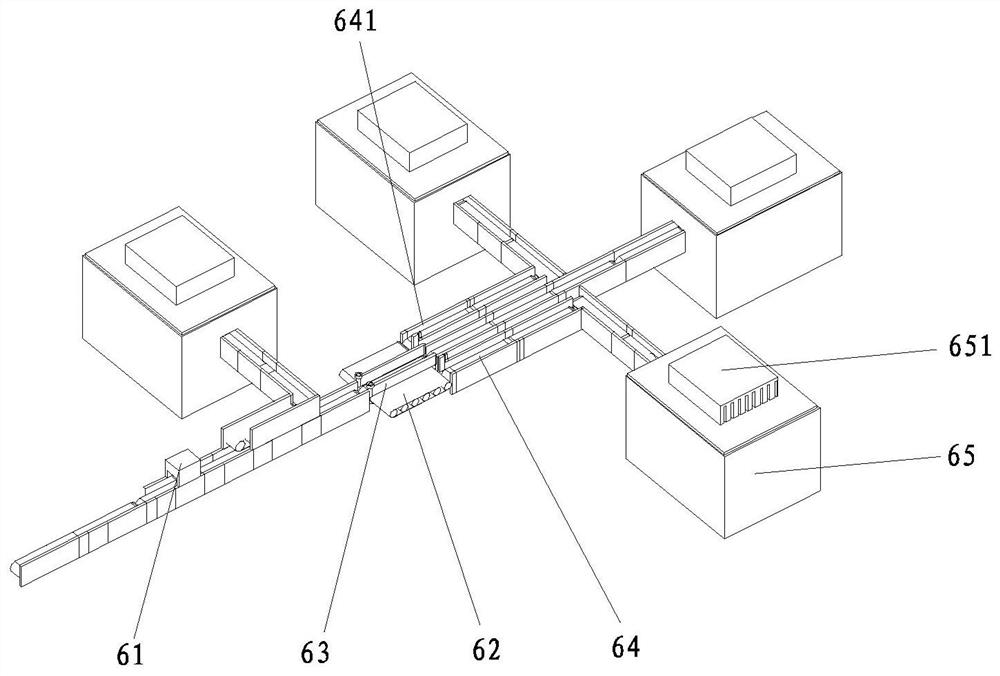

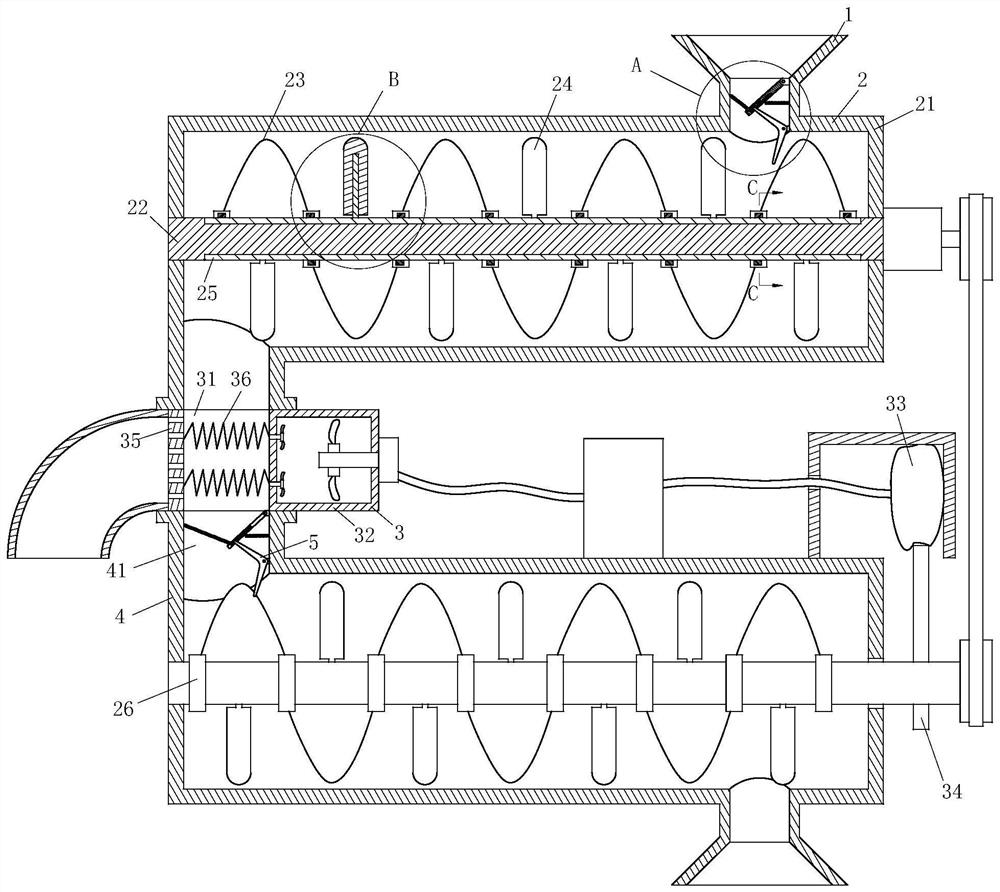

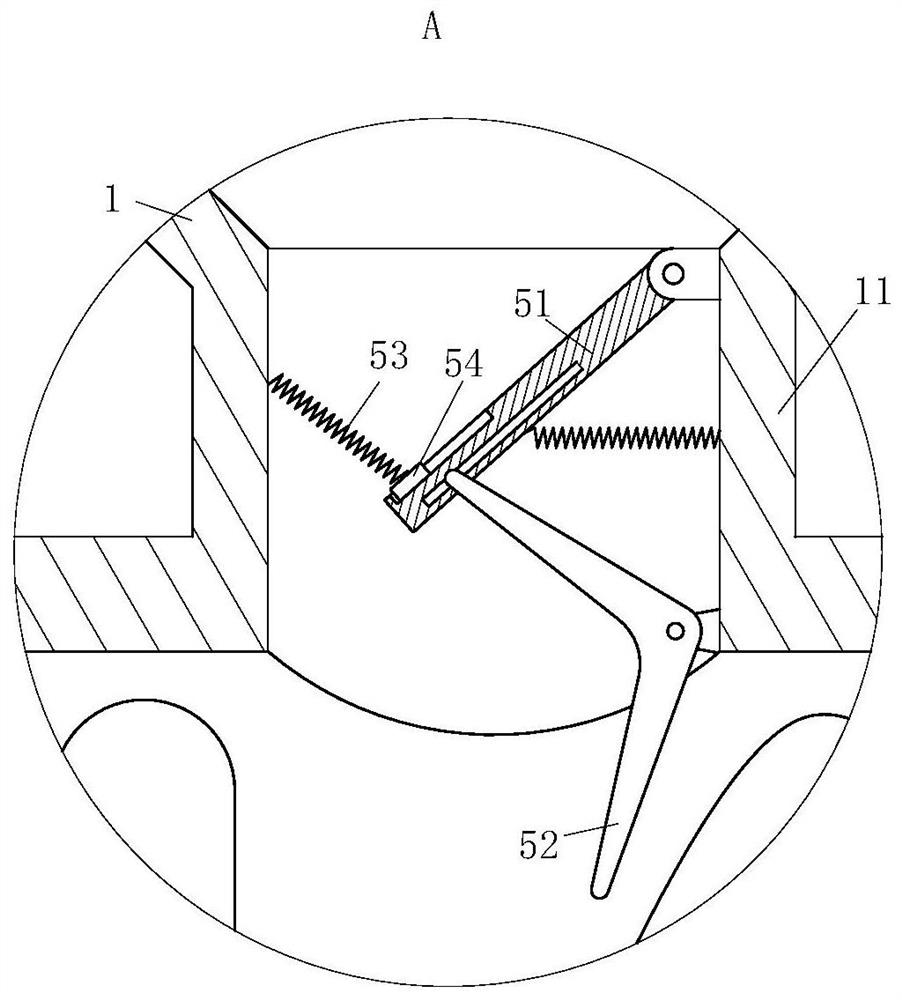

Mahjong tile rubbing and washing device of mahjong machine

The invention discloses a mahjong tile rubbing and washing device of a mahjong machine. The device comprises a rack, a shell and a drive motor, wherein a mahjong tile rubbing and washing bin of a cylinder structure is arranged in the shell; a mahjong tile inlet is formed at the top of the mahjong tile rubbing and washing bin; a rotary shaft is arranged on the mahjong tile rubbing and washing bin; an umbrella-shaped turntable is mounted on the rotary shaft; a turntable covering surface covers the periphery of the umbrella-shaped turntable; an output shaft of the drive motor stretches into the mahjong tile rubbing and washing bin; spray heads are uniformly distributed on the top surface and side surface of the mahjong tile rubbing and washing bin; a mahjong tile outlet is formed on the rear side of the mahjong tile rubbing and washing bin; a drying room is arranged behind the shell; and a conveying track and a drying device are arranged in the drying room. Due to the structure, the mahjong tiles entering the mahjong tile rubbing and washing bin can be cleaned by the spray heads; after the cleaning, the mahjong tiles can directly enter the drying room for drying; the cylinder structure enables uniform dispersion of the mahjong tiles; the mahjong tiles cleaned by the spray heads are directly dried; and therefore, the mahjong tiles are cleaned, secondary pollution of the mahjong tiles is avoided, and the cleaning effect is good.

Owner:JIANGSU DANBOM MECHANICAL & ELECTRICAL

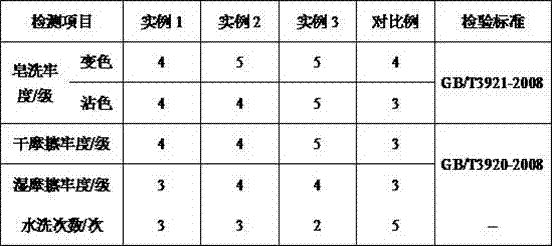

Preparation method of adsorption type biological enzyme soaping agent for reactive dyes

InactiveCN107384630ALow water solubilityReduce the amount of floating colorNon-surface-active detergent compositionsDetergent compounding agentsThree levelKeratin

The invention discloses a preparation method of an adsorption type biological enzyme soaping agent for reactive dyes, belonging to the technical field of preparation of printing and dyeing auxiliary agents. The preparation method comprises the following steps of firstly, culturing and fermenting white-rot fungi by using a homemade fermentation medium, centrifuging the prepared fermented liquid to obtain crude enzyme liquid, and then preparing alkaline laccase by taking the crude enzyme liquid as a raw material; preparing a wool keratin solution by taking wool as a raw material, modifying the prepared wool keratin solution, then mixing the modified solution with the alkaline laccase, Tween-80 / liquid paraffin, and the like, and carrying out centrifugal separation; after that, collecting precipitate, and washing the precipitate with acetone and isopropyl alcohol; finally, drying to obtain the adsorption type biological enzyme soaping agent for the reactive dyes. The soaping agent prepared by the method has a better soaping effect and a better anti-staining effect, thus enabling the color fastness to soaping and fastness to rubbing of fabrics subjected to soaping to reach three-level or above; furthermore, the soaping agent provided by the invention does not generate foam in a soaping process, so that the washing times of the fabrics can be reduced, and the energy consumption is greatly reduced.

Owner:朱文杰

Desizing device for textile fabric production

InactiveCN112813613AAvoid contaminationClean thoroughlyMechanical cleaningPressure cleaningSlurryMechanical engineering

The invention relates to the technical field related to textile fabric production, and discloses a desizing device for textile fabric production. The desizing device comprises a washing tank; reversing wheels are movably mounted on two sides of the top of the washing tank respectively; a cleaning brush is fixedly mounted at the bottom of an inner cavity of the washing tank; a partition plate is fixedly mounted in the middle of the inner wall of the washing tank; and a washing cavity is formed in the inner wall of the washing tank. According to the invention, the partition plate is arranged in the washing tank, so that a large amount of slurry floats to one side in the washing cavity in a fabric treatment process; meanwhile, movable magnetic blocks are arranged in a cleaning wheel, the movable magnetic blocks attract each other through rotation of the cleaning wheel, and a fabric is blown by airflow, so that cleaning is achieved; and the airflow in liquid is upward and acts on the part near the fabric, and when the fabric leaves from the liquid, slurry blocks are pushed away through the airflow, so that the phenomenon of secondary contamination after cleaning is avoided, and finally the purpose of avoiding secondary slurry contamination is achieved.

Owner:王骏

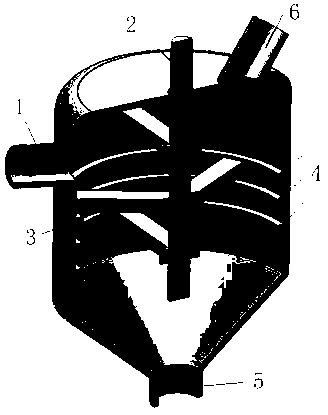

Tile cleaning device of mahjong machine

The invention discloses a tile cleaning device of a mahjong machine. The tile cleaning device comprises a rack, a shell and a drive motor. A tile rubbing and cleaning bin of a conical structure is arranged in the shell, a tile inlet is formed in the top of the tile rubbing and cleaning bin, a rotary shaft is arranged on the tile rubbing and shuffling bin and provided with a rotary disc with protrusions and pits, and the periphery of the rotary disc is coated with a rotary disc covering face. An output shaft of the drive motor stretches into the tile rubbing and cleaning bin, spray heads are evenly arranged on the side faces of the tile rubbing and cleaning bin, a tile outlet is formed in the rear side of the tile rubbing and cleaning bin, a drying chamber is arranged behind the shell, and a conveying rail and a drying device are arranged in the drying chamber. By means of the structure, after entering the tile rubbing and shuffling bin, mahjong tiles can be cleaned through the spray heads and can directly enter the drying chamber to be dried after being cleaned, the mahjong tiles are scattered very evenly by means of the tubular structure, and the mahjong tiles are directly dried after being cleaned through the spray heads, so that the mahjong tiles are cleaned and prevented from being contaminated again, and the cleaning effect is good.

Owner:JIANGSU DANBOM MECHANICAL & ELECTRICAL

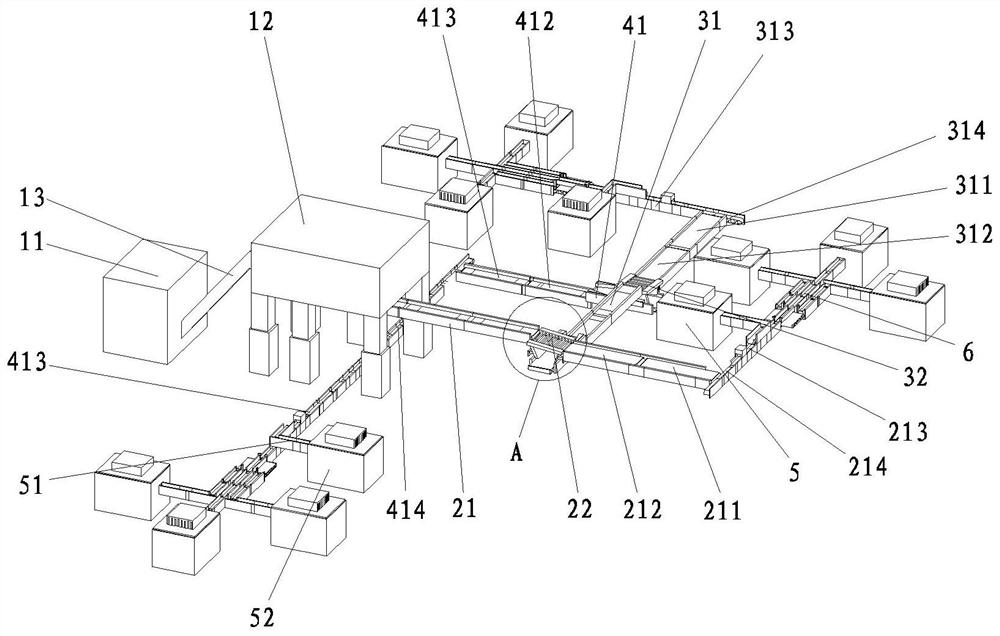

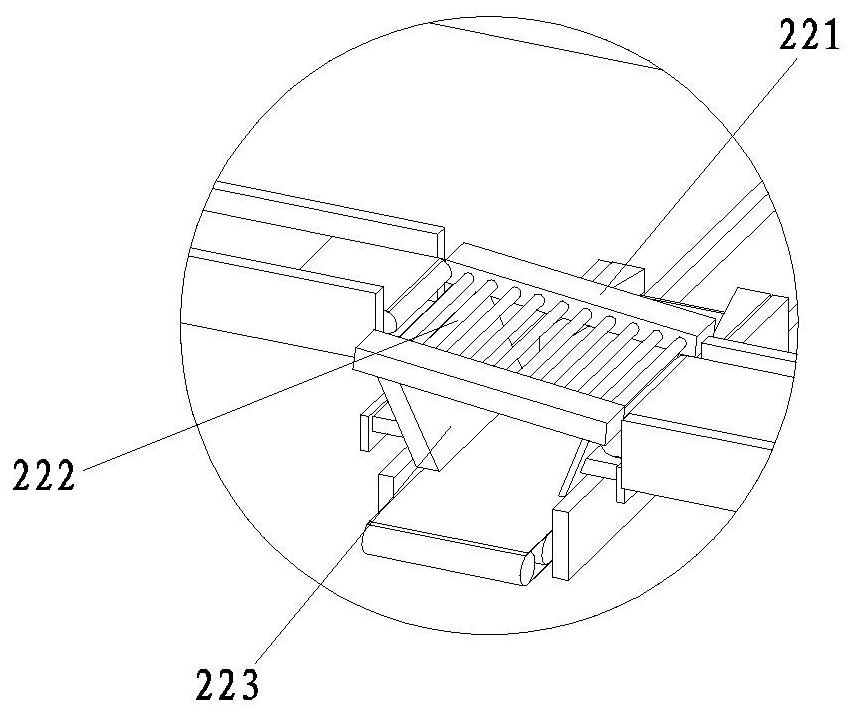

Household garbage classification, recovery and harmless treatment system

PendingCN112958454AImprove classification efficiencyAvoid re-contaminationMagnetic separationSortingProcess engineeringManufacturing engineering

The invention discloses a household garbage classification, recovery and harmless treatment system. The system comprises a recovering box, a cleaning box and a conveying ladder connected with the recovering box and the cleaning box; an outlet is formed in the lower end of the cleaning box; a first-stage conveying belt is arranged below the outlet; the first-stage conveying belt is provided with a first-stage distinguishing device; a second-stage conveying belt is arranged below the first-stage distinguishing device; a second-stage distinguishing device is arranged on the second-stage conveying belt; a third-stage conveying belt is arranged below the second-stage distinguishing device; and each of the discharging ends of the first-stage conveying belt, the second-stage conveying belt and the third-stage conveying belt is provided with an iron part recovering device and a screening device. Compared with the prior art, the system has the advantages that garbage can be automatically classified and recovered, and the garbage classification efficiency can be improved.

Owner:福建名盛美洁环境工程有限公司

Mahjong rubbing device

The invention discloses a mahjong rubbing device. The device comprises a rack, a shell and a driving motor, wherein a mahjong rubbing and shuffling bin with a conical structure is arranged in the shell; a mahjong inlet is formed in the top of the mahjong rubbing and shuffling bin; a rotating shaft is arranged on the mahjong rubbing and shuffling bin; an umbrella-shaped rotating disc is mounted on the rotating shaft; a rotating disc coverage surface covers the periphery of the umbrella-shaped rotating disc; an output shaft of the driving motor stretches into the mahjong rubbing and shuffling bin; nozzles are arranged on the side ace of the mahjong rubbing and shuffling bin; a mahjong outlet is formed in the rear side of the mahjong rubbing and shuffling bin; a drying room is arranged behind the shell; and a conveying rail and a drying device are arranged in the drying room. With the adoption of the structure, while entering the mahjong rubbing and shuffling bin, the mahjong can be cleaned by the nozzles and can directly enter the drying room for drying after cleaning completion. According to the cylindrical structure, the mahjong can be uniformly scattered and is directly dried by the nozzles after cleaning, so that the mahjong can be cleaned up and is prevented from being contaminated again, so that the cleaning effect is good.

Owner:JIANGSU DANBOM MECHANICAL & ELECTRICAL

A kind of activated carbon grinding process

ActiveCN109351419BQuality improvementGuaranteed drynessGrain treatmentsChemicalsActivated carbonBacterial killing

Owner:宁夏浦士达环保科技有限公司

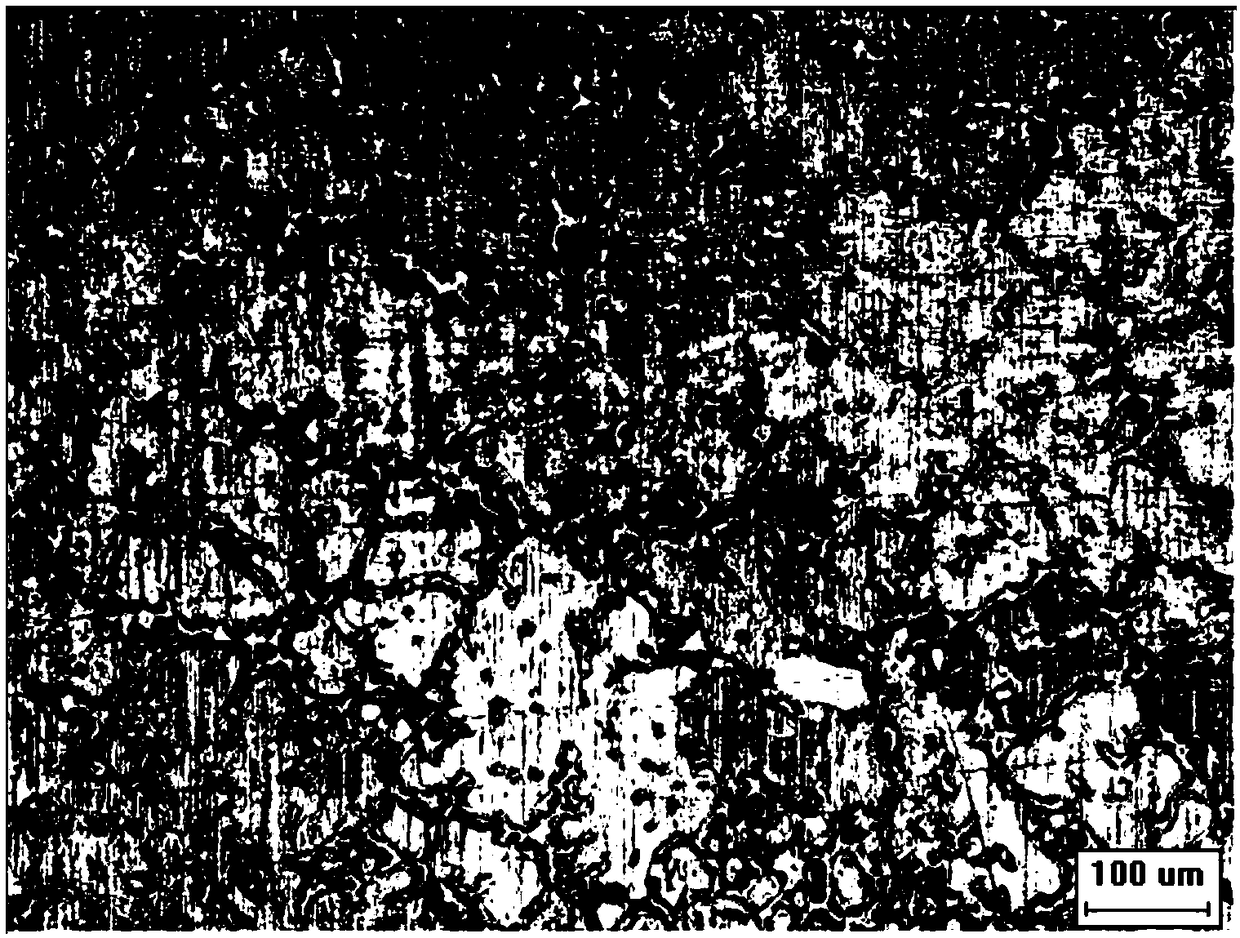

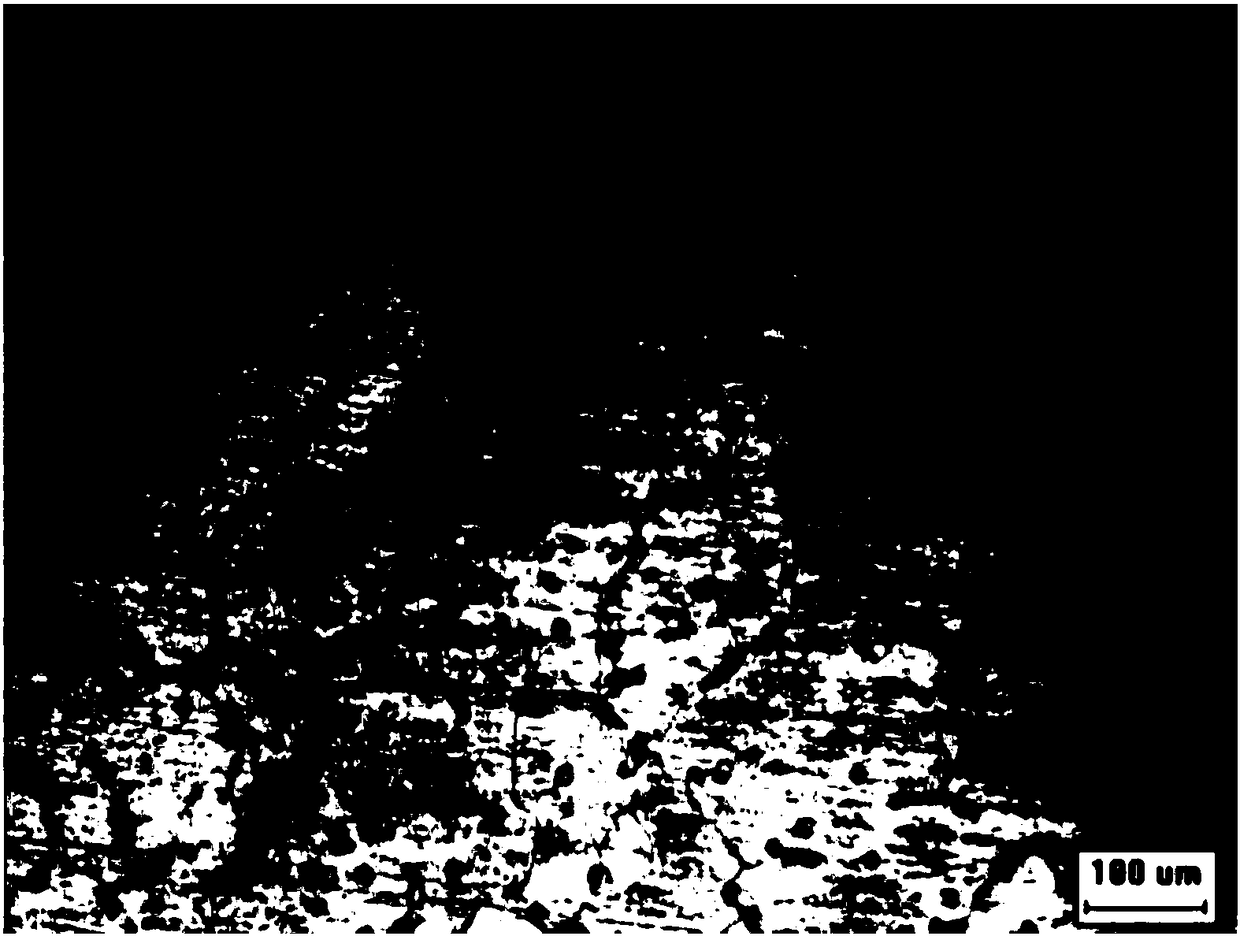

Method of preparing high performance magnesium alloy tube blank by using tube blank mold

The invention relates to a method of preparing a high performance magnesium alloy tube blank by using a tube blank mold and belongs to the field of metal materials. The method comprises the followingsteps: (1) mixing and smelting raw materials in mixed gas of N2 and SF6 according to proportion of a magnesium alloy; (2) preheating the tube blank mold to 80-450 DEG C; and (3) pouring a magnesium alloy melt into the preheated tube blank mold to condense the alloy to obtain the magnesium alloy tube blank, specifically, in the whole process, a rotary magnetic field can be applied at the same time,the electromagnetic stirring frequency is 2-30 Hz, the electromagnetic stirring current is 60-500 A, and the mode of applying the magnetic field is as follows: the rotary magnetic field can be applied or not in the pouring process, and the rotary magnetic field is applied in the condensing process. The method is suitable for various magnesium alloys, short in process flow, easy to operate and convenient to control, and can meet the demand in actual application for performance of the magnesium alloy. According to the method, a self-made mold is adopted and a cavity is of a tube blank shape, sothat the stirring effect is good, the obtained magnesium alloy casting is uniform in inner and outer tissues and fine in grain size, and the mechanical properties are improved obviously.

Owner:SHENYANG POLYTECHNIC UNIV

Fire hose cleaning device

The invention discloses a fire hose cleaning device. The device comprises a second roller, a blow-drying box and a base. A water drainage box is welded to one end of the top of the base. The top end and the bottom end of the interior of the water drainage box are rotationally connected with rotary shafts through shaft sleeves correspondingly. The inner sides of two rotary shafts, close to the topof the base, are rotationally connected with a first roller. Slots are formed in the inner sides of the other two rotary shafts, away from the top of the base, correspondingly. Elastic plug pins are connected into the two slots correspondingly in a sleeving mode. One ends of the two elastic plug pins are elastically connected with the second roller through springs correspondingly. A cleaning box is welded to the top of the base. According to the fire hose cleaning device, the water drainage box is arranged at the top of the base and internally provided with the two rollers, the two rollers clamp a hose between the inner sides of the two rollers, when the hose moves, water in the hose is drained out under extrusion of the two rollers, and further cleaning is facilitated.

Owner:成都尚智恒达科技有限公司

oleophobic hydrophilic antifouling antibacterial shoes

ActiveCN111851061BReduce surface tensionIncrease surface tensionStain/soil resistant fibresBiochemical fibre treatmentEpoxyPolymer science

Owner:东莞市喜宝体育用品科技有限公司

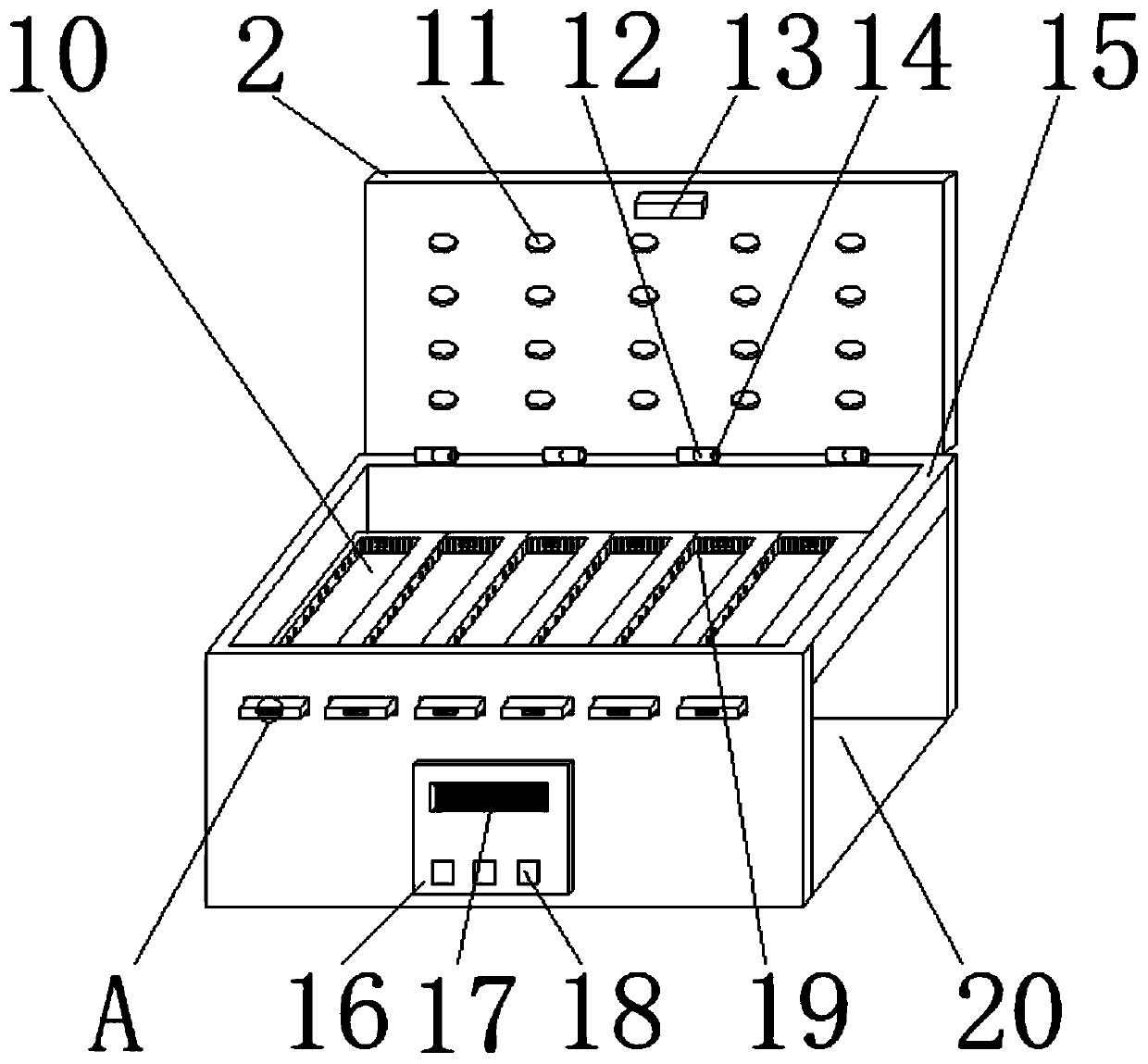

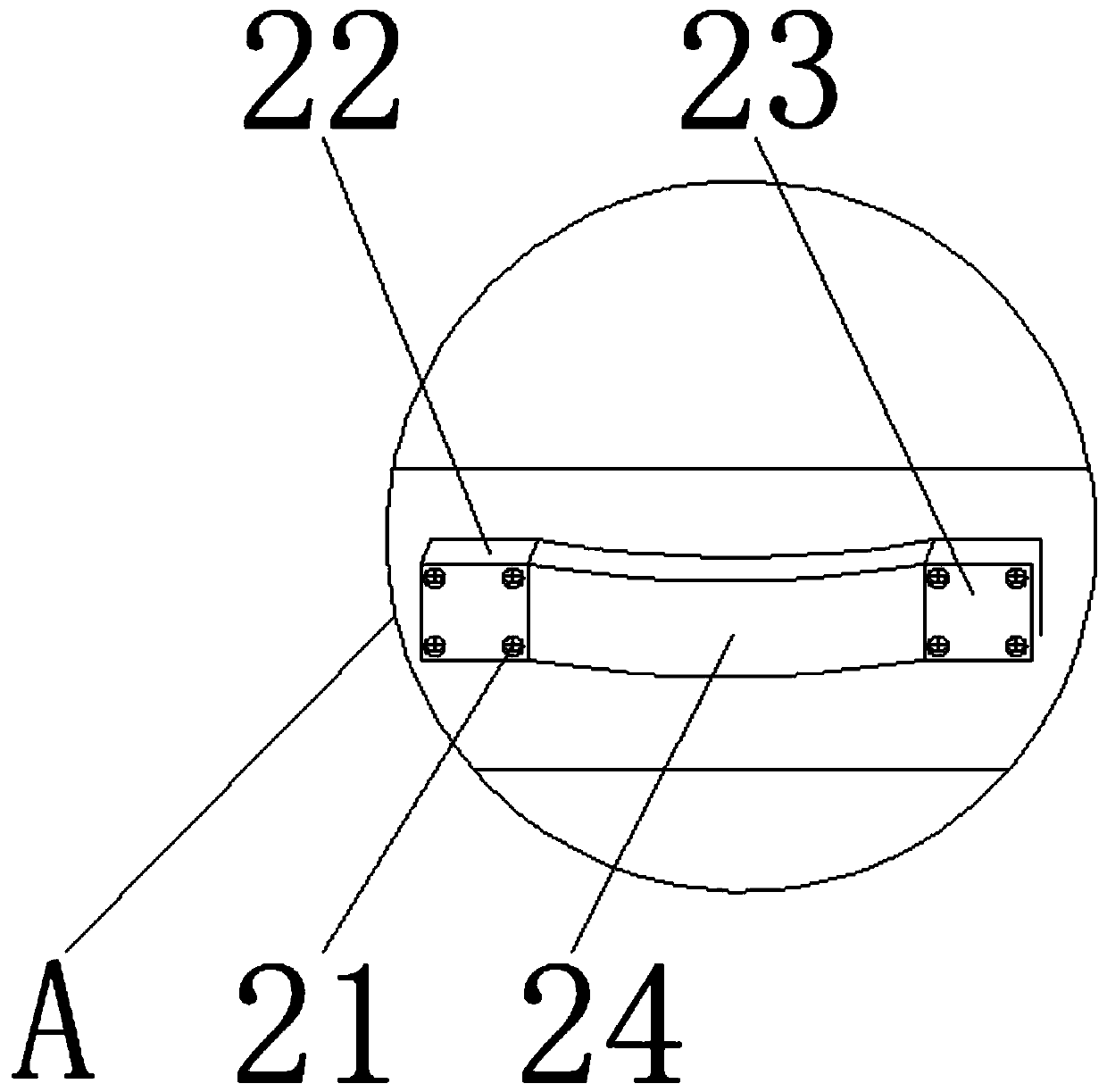

Efficient cable material drying device

InactiveCN111023773AEasy to dryAccelerate evaporationDrying machines with progressive movementsDrying solid materialsWorkbenchHandrail

The invention discloses an efficient cable material drying device. The device comprises a workbench, a drying mechanism and a placing mechanism, wherein the drying mechanism is located on the outer surface of the top end of the workbench; the drying mechanism comprises a top cover; the outer surface of the bottom of the top cover is rotatably connected with shaft sleeves; and the inner surfaces ofthe shaft sleeves are rotatably connected with bearings. Through the arrangement of the top cover, a drying area, heat dissipation holes, the shaft sleeves, a locking bar, the bearings, a drying box,an operation panel, a display screen, control buttons, drying holes and a mounting groove, a cable material can be conveniently dried, moisture of the cable material is convenient to evaporate continuously in the drying area, disinfection and sterilization of the cable material are also facilitated, and the quality of the cable material is guaranteed. A collecting box, a first connecting strip, mounting holes, a second connecting strip and a handrail are arranged, so that the dried cable material is conveniently collected, the cable material is prevented from being contaminated again, the device is easy to manufacture, low in cost and convenient to use, and better application prospects are brought.

Owner:徐州创联智谷科技企业孵化器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com