Preparation method of chelating dispersant

A technology for chelating dispersant and raw materials, which is applied in the field of preparation of chelating dispersant, can solve the problem of uncoordinated properties of chelating dispersant, and achieve the effects of good flocculation and sedimentation effect, good dispersion, and avoidance of contamination again.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

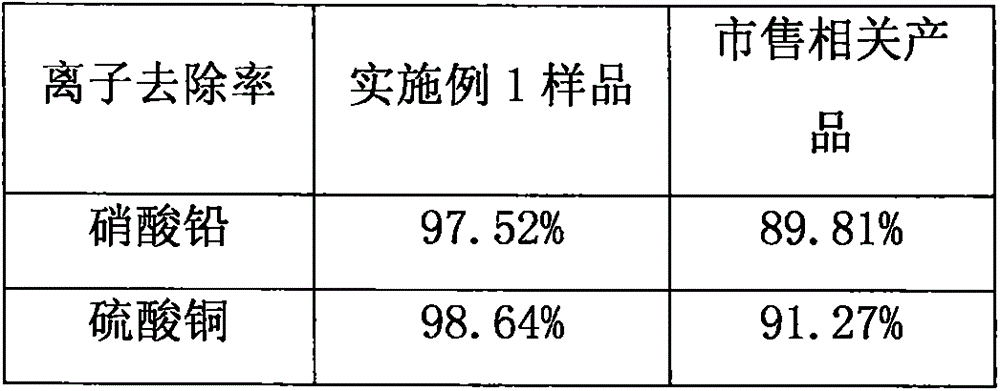

Examples

Embodiment 1

[0016] A kind of preparation method of chelating dispersant, each raw material is measured in parts by mass, comprises the following steps:

[0017] a. Dissolve 10 parts of maleimide and 12 parts of acrylamide in 65 parts of deionized water, and dissolve 0.2 part of sodium persulfate in 30 parts of deionized water to form a solution for later use;

[0018] b. Put 20 parts of polyoxyethylene lauryl ether-15 maleic anhydride monoester sodium salt, 15 parts of diallylamine and 234 parts of deionized water into the reactor, stir, dissolve, and heat up to 70°C;

[0019] c. Add 1 / 3 volume of maleimide and acrylamide aqueous solution and 1 / 4 volume sodium persulfate aqueous solution to the reaction kettle to initiate the reaction and keep it warm for 30 minutes;

[0020] d. Within 2 hours, drop the remaining maleimide and acrylamide aqueous solution, sodium persulfate aqueous solution and 20 parts of acrylic acid into the reactor of step b, and then keep the reaction at 80°C for 2 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com