Surface sticky fluff removing device for garment production and processing

A technology for sticking wool and clothing, applied in the field of garment processing, can solve the problems of pollution, the sticky wool roller is not easy to remove, and the efficiency of sticky wool processing is low, and the effect of increasing the cleanliness is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

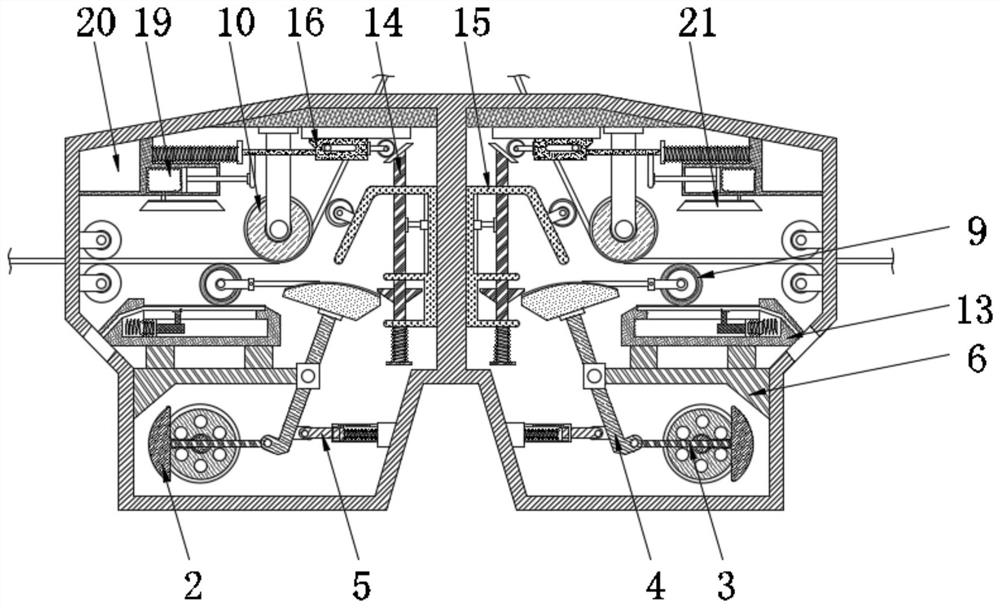

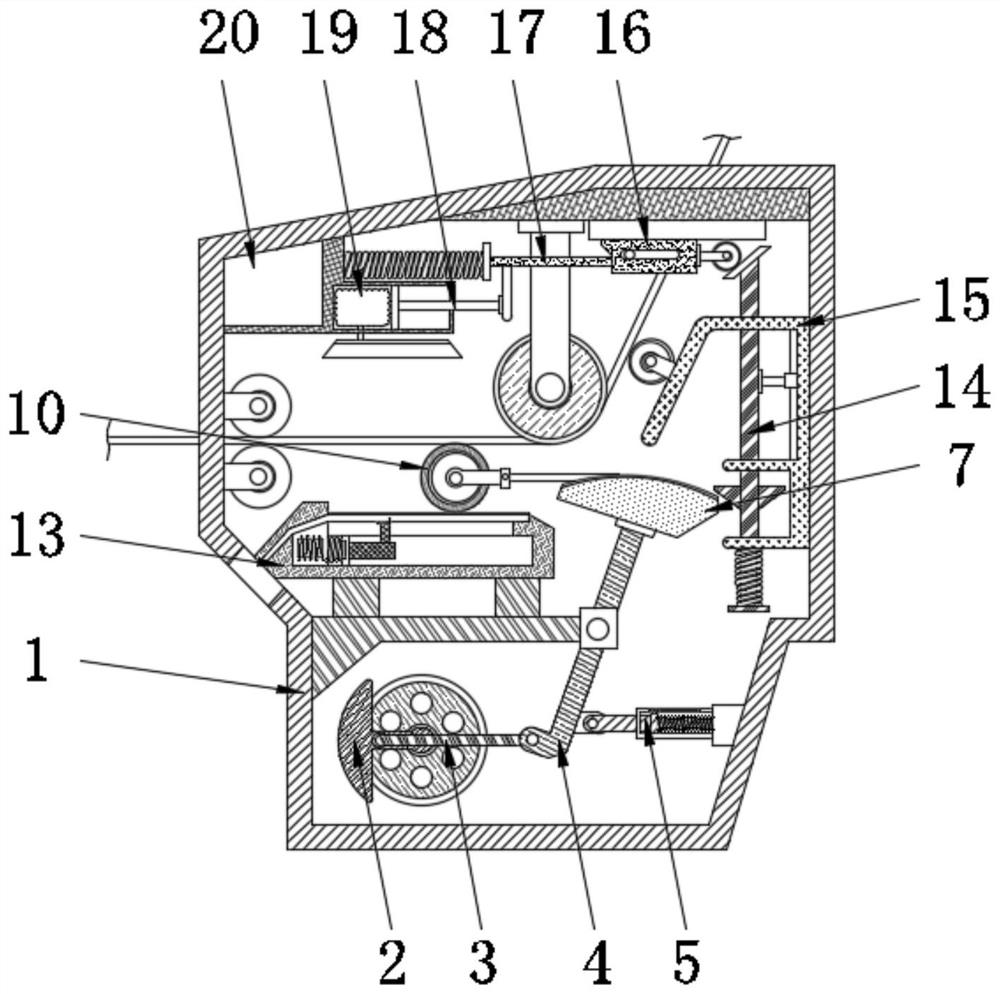

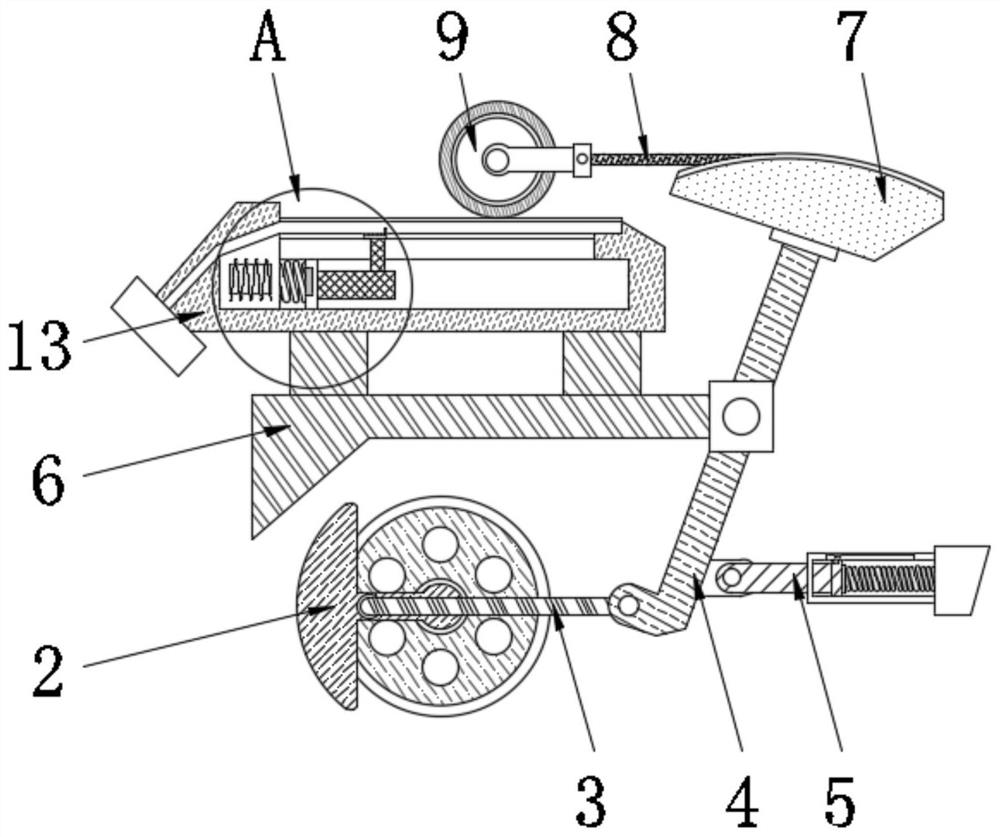

[0021] The invention provides a surface sticky hair removal device for garment production and processing. figure 1 to attach Figure 5 Shown: including the processing chamber 1, the internal rotation of the processing chamber 1 is installed with the rotating plate 2, and the rotating plate 2 is fixedly installed on the output end of the motor. Rod 4, the inner surface of movable rod 4 is movably connected with sub-rod 5, and the outer surface of sub-rod 5 is provided with corresponding sleeve in the inside of processing chamber 1, and the inner end of sub-rod 5 is fixedly connected with spring, and sub-rod 5 5 and the processing chamber 1 are provided with a metal block group 501, the movable rod 4 is movably installed on the inner end of the support seat 6, and the top of the movable rod 4 is fixedly installed with a fan-shaped plate 7, and the surface of the fan-shaped b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com