Preparation method of adsorption type biological enzyme soaping agent for reactive dyes

A reactive dye and adsorption-type technology, applied in the direction of non-surface active detergent composition, detergent compounding agent, chemical equipment and methods, etc., can solve the problems of reduced soaping effect, stripping, and excessive foaming, etc., to prevent re- The effects of staining fabrics, reducing washing water consumption, and removing residual floating colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

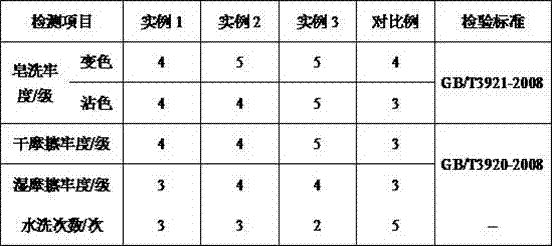

Examples

example 1

[0020] Weigh 50g ammonium chloride, 1.5g potassium dihydrogen phosphate, 1.0g copper sulfate pentahydrate, 1g sodium chloride, 0.8g magnesium sulfate, 100g bran, 10g corn flour, 15g sucrose, 0.5g calcium chloride, add 1.0 In L deionized water, stir at 200r / min for 20min to obtain a fermentation medium, then adjust the pH of the medium to 9.0 with a mass fraction of 1% sodium hydroxide solution, and inoculate the white rot fungus into the fermentation medium according to the inoculum size of 10%. At 30°C, shake and ferment at 200r / min for 8 days, then add 9L of deionized water, shake at 28°C at 200r / min for 2h to obtain a fermentation broth, then place the fermentation broth in a high-speed centrifuge, Centrifuge at 10000r / min for 8min, collect the supernatant to obtain a crude enzyme solution, then add 2.0L tert-butanol and 200g ammonium sulfate to the crude enzyme solution, let it stand at 25°C for 1h, then transfer it to a centrifuge, / min centrifuge for 12min, collect the p...

example 2

[0021]Weigh 53g ammonium chloride, 1.8g potassium dihydrogen phosphate, 1.1g copper sulfate pentahydrate, 1g sodium chloride, 0.9g magnesium sulfate, 110g bran, 11g corn flour, 18g sucrose, 0.7g calcium chloride, add 1.1 In L deionized water, stir at 250r / min for 25min to obtain a fermentation medium, then adjust the pH of the medium to 9.3 with a mass fraction of 1% sodium hydroxide solution, and inoculate the white rot fungus into the fermentation medium according to the inoculum size of 13%. At 31°C, shake and ferment at 220r / min for 9 days, then add 9L of deionized water, and shake at 220r / min for 2h at 29°C to obtain a fermented liquid, then place the fermented liquid in a high-speed centrifuge, Centrifuge at 11000r / min for 9min, collect the supernatant to obtain a crude enzyme solution, then add 2.2L tert-butanol and 210g ammonium sulfate to the crude enzyme solution, let it stand at 28°C for 1h, then transfer it to a centrifuge, / min centrifuge for 14min, collect the pr...

example 3

[0022] Weigh 55g ammonium chloride, 2.0g potassium dihydrogen phosphate, 1.2g copper sulfate pentahydrate, 2g sodium chloride, 1.0g magnesium sulfate, 120g bran, 12g corn flour, 20g sucrose, 0.8g calcium chloride, add 1.2 Stir in L deionized water for 30 min at 300 r / min to obtain a fermentation medium, then adjust the pH of the medium to 9.5 with a mass fraction of 1% sodium hydroxide solution, and inoculate the white rot fungus into the fermentation medium according to the inoculum size of 15%. At 32°C, shake and ferment at 240r / min for 10 days, then add 10L of deionized water, and shake at 240r / min for 3h at 30°C to obtain a fermented liquid, then place the fermented liquid in a high-speed centrifuge, Centrifuge at 12000r / min for 10min, collect the supernatant to obtain a crude enzyme solution, then add 2.4L tert-butanol and 220g ammonium sulfate to the crude enzyme solution, let it stand at 30°C for 2h, then transfer it to a centrifuge, / min centrifuge for 15min, collect t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com