Medical apparatus packing bag

A medical device and packaging bag technology, applied in the field of medical device packaging bags, can solve the problems of medical devices being re-infected and easily punctured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

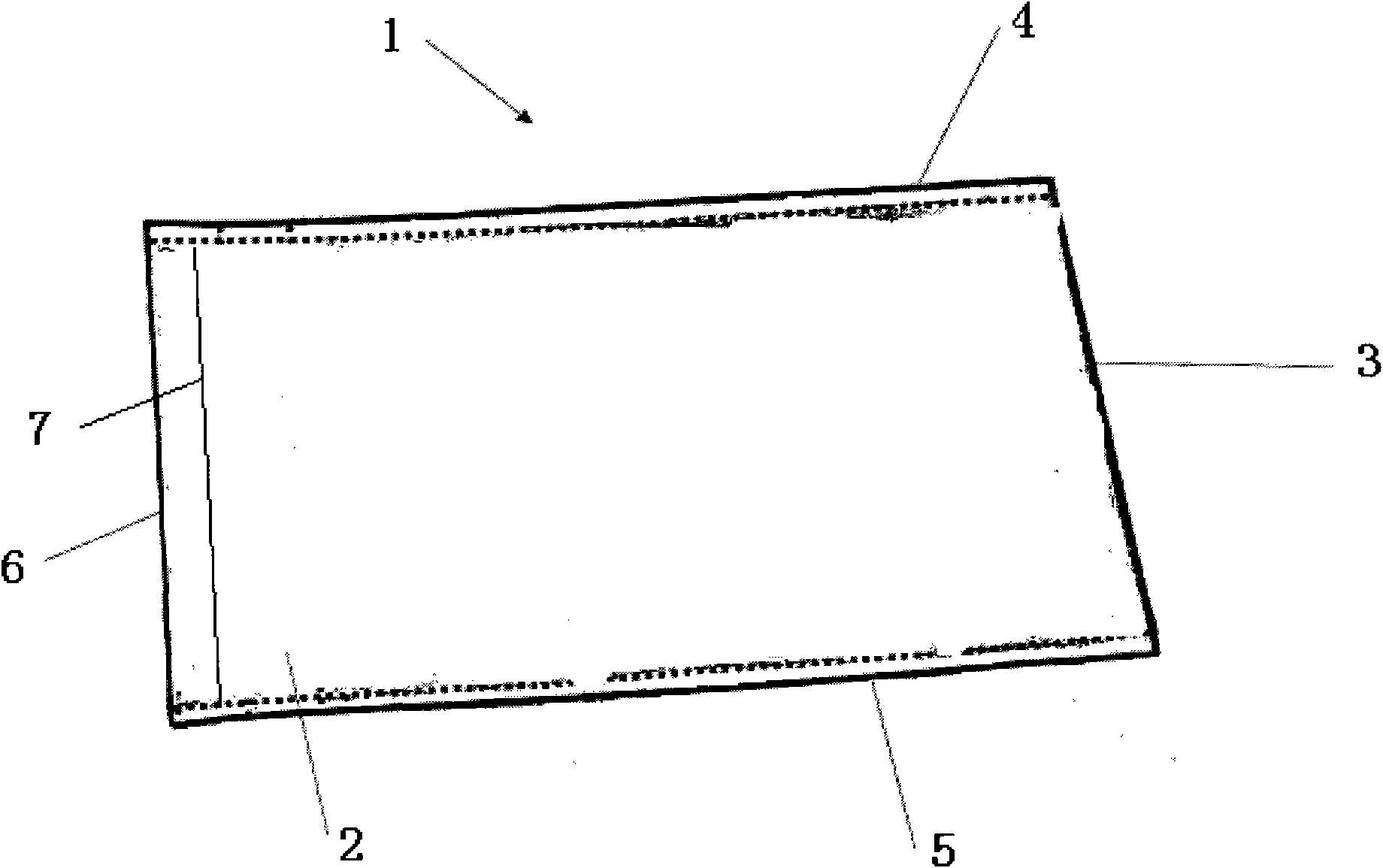

Embodiment 1

[0027] refer to figure 1 , the medical device packaging bag 1 of the present invention is formed by folding a laminated polyethylene layer and a nylon layer to form a sealing edge 3, a first side 2 and a second side (not shown in the figure), and the first side 2 and the second side are opposite to each other. Sides 4 and 5 are thermally bonded to form opening 6 .

[0028] The total thickness of the laminated polyethylene layer and nylon layer was 0.5 mm, and the ratio of the thickness of the polyethylene layer to the nylon layer was 9:1. The lamination is achieved by a lamination method commonly used in the art, such as a co-extrusion method.

[0029] The polyethylene layer is prepared from commercially available medical polyethylene. The nylon layer is prepared by using commercially available medical nylon.

[0030] After a medical device such as medical scissors is accommodated in the medical device packaging bag 1 of the present invention, the opening 6 is bonded along ...

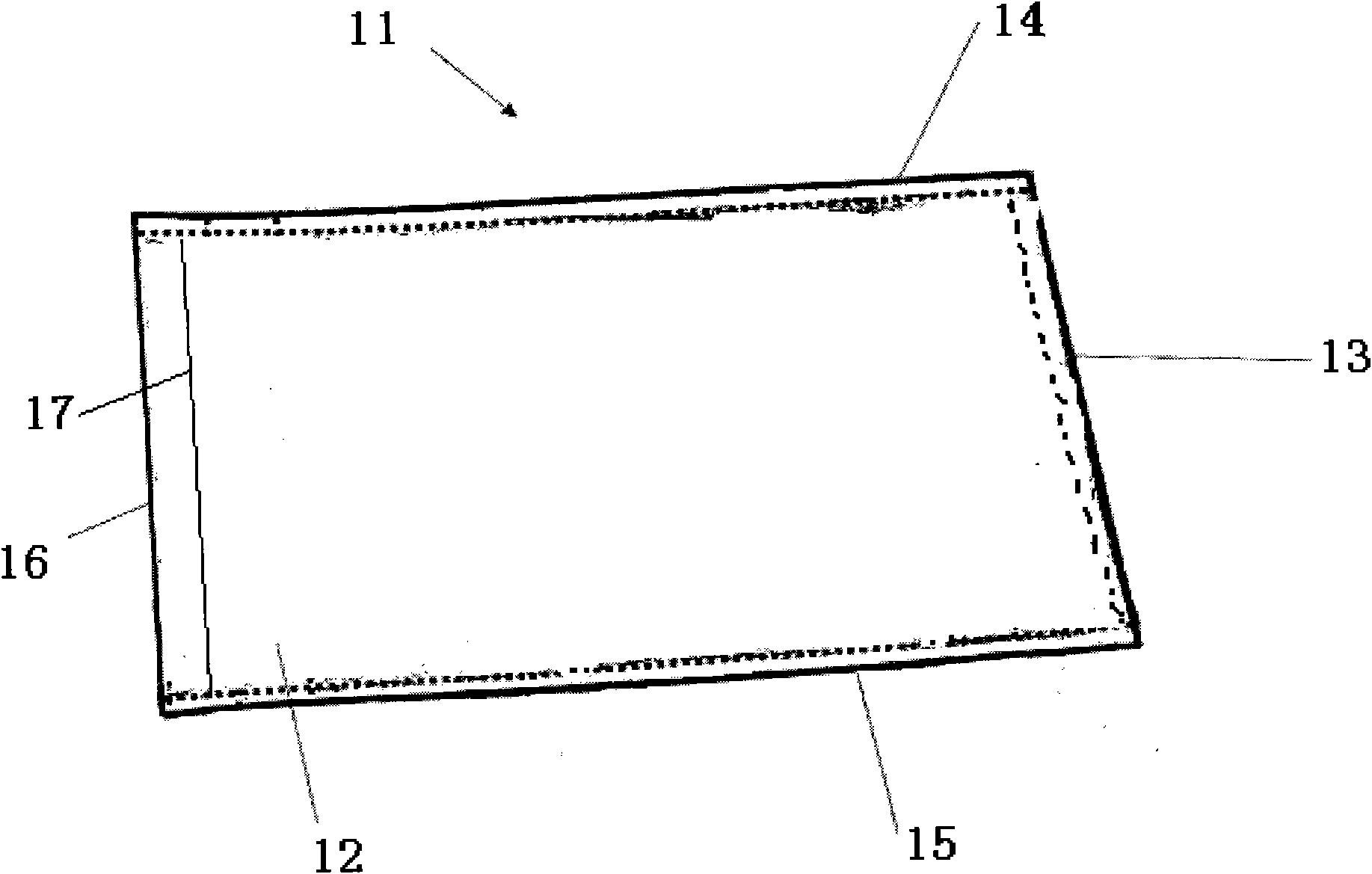

Embodiment 2

[0032] refer to figure 2 , another medical device packaging bag 11 of the present invention, comprising a first side 12 formed of a laminated polyethylene layer and a nylon layer and a second layer formed of a laminated polyethylene terephthalate layer and a nylon layer Two sides (not shown), the first side 12 and the second side are thermally bonded at the opposite sides 14 and 15 and the third side 13 to form the opening 16 .

[0033] The total thickness of the laminated polyethylene layer and nylon layer was 1.0 mm, and the ratio of the thickness of the polyethylene layer to the nylon layer was 5:5.

[0034] The total thickness of the laminated polyethylene terephthalate layer and the nylon layer was 0.8 mm, and the thickness ratio of the polyethylene terephthalate layer and the nylon layer was 5:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com