Method of preparing high performance magnesium alloy tube blank by using tube blank mold

A magnesium alloy, high-performance technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of limited application and promotion, poor plasticity of magnesium alloys, etc., and achieve short process flow, improved mechanical properties, and uniform internal and external structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

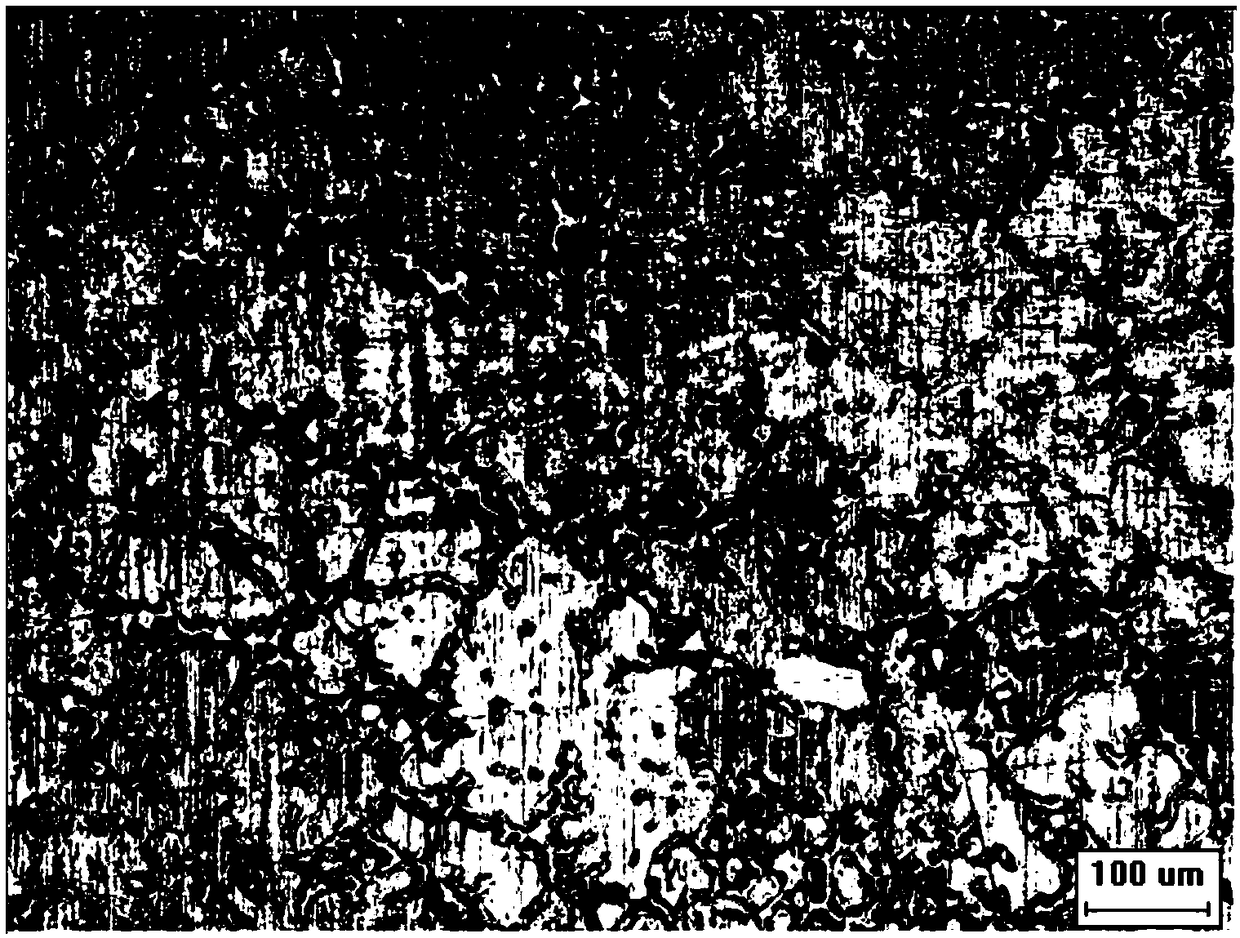

Embodiment 1

[0042] A method for preparing a high-performance magnesium alloy tube blank with a tube blank mold, the magnesium alloy used is AZ91, the chemical composition and mass percentage of the magnesium alloy used are Al: 8.5-9.5%, Zn: 0.45-0.91%, Mn: 0.17-0.4%, the balance is Mg.

[0043] The preparation method, the specific steps are as follows:

[0044] (1) Melting

[0045] Weigh the raw materials according to the composition ratio of the AZ91 magnesium alloy, mix the raw materials and put them in the resistance furnace for melting to obtain the AZ91 magnesium alloy melt; during the melting process, N 2 and SF 6 The mixed gas is used as the shielding gas, wherein, in the mixed gas, SF 6 The mass concentration is 0.1%, and the nitrogen mass concentration is SF 6 100 times;

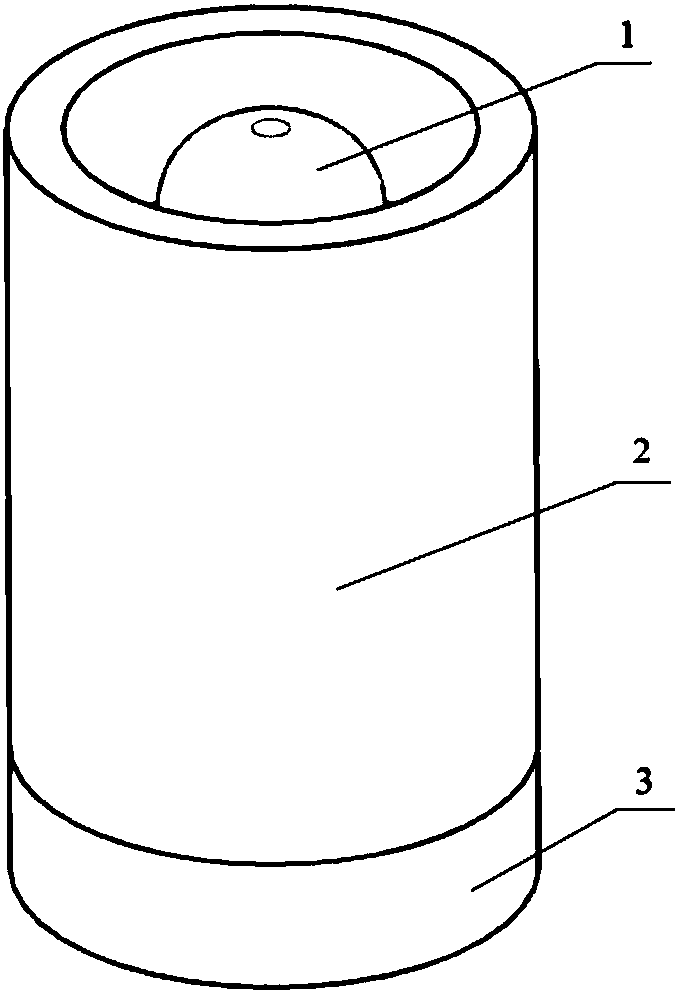

[0046] (2) Preheating

[0047] Preheating the tube blank mold with a cavity in the shape of a tube blank to obtain a preheated tube blank mold; wherein, the preheating temperature is 450°C, and the prehea...

Embodiment 2

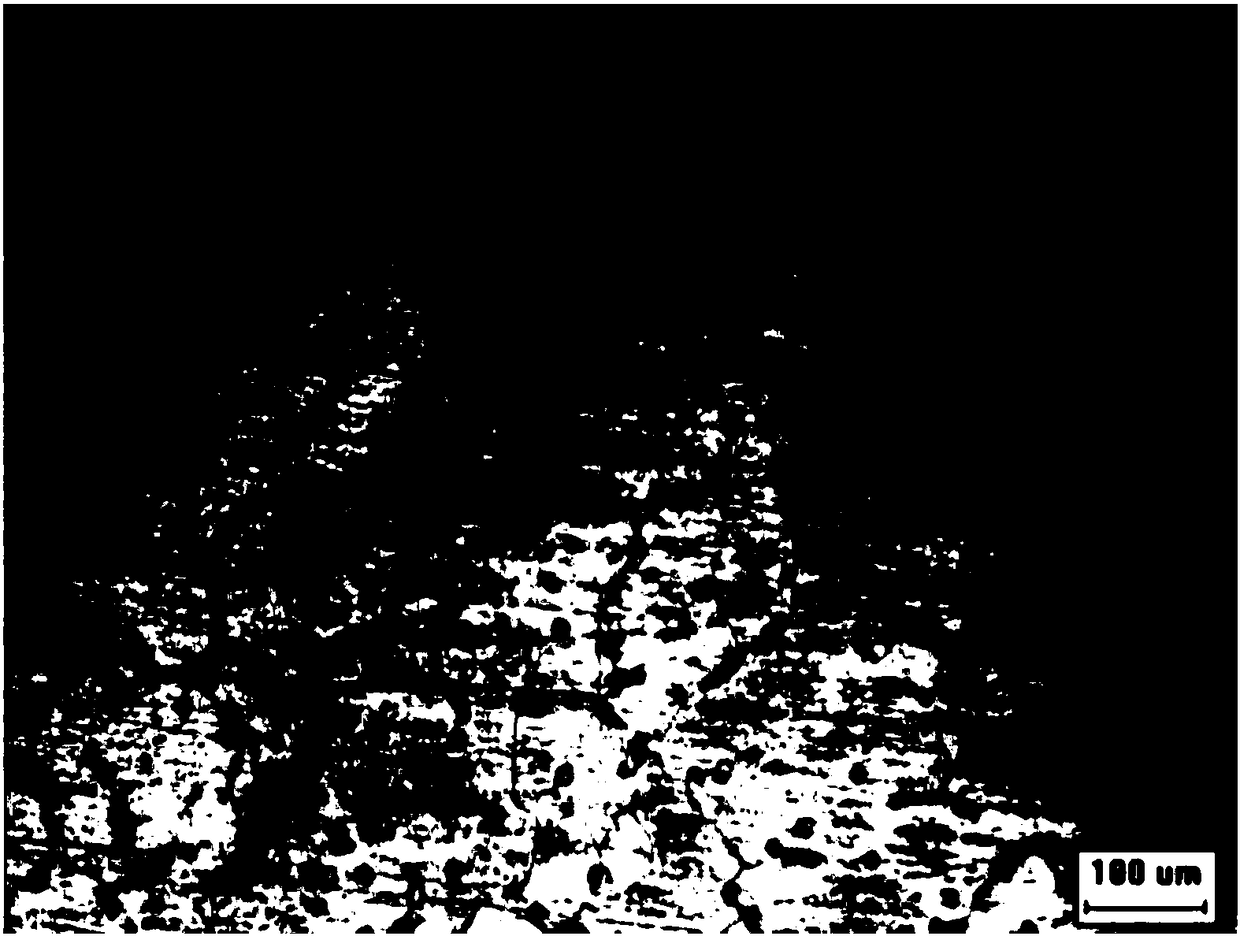

[0055] A method for preparing a high-performance magnesium alloy tube blank with a tube blank mold, the magnesium alloy used is AZ31, the chemical composition and mass percentage of the magnesium alloy used are Al: 2.5-3.0%, Zn: 0.70-1.3%, Mn: 0.17-0.2%, the balance is Mg.

[0056] The preparation method, the specific steps are as follows:

[0057] (1) Melting

[0058] Weigh the raw materials according to the composition ratio of the AZ31 magnesium alloy, mix the raw materials and put them in the resistance furnace for melting to obtain the AZ31 magnesium alloy melt; during the melting process, N 2 and SF 6 The mixed gas is used as the shielding gas, wherein, in the mixed gas, SF 6 The mass concentration is 0.4%, and the nitrogen mass concentration is SF 6 100 times;

[0059] (2) Preheating

[0060] Preheating the tube blank mold with a cavity in the shape of a tube blank to obtain a preheated tube blank mold; wherein, the preheating temperature is 80°C, and the preheati...

Embodiment 3

[0068] A method for preparing a high-performance magnesium alloy tube blank with a tube blank mold, the magnesium alloy used is AM50, the chemical composition and mass percentage of the magnesium alloy used are Al: 4.5-5.3%, Zn: 0.2%, Mn: 0.28- 0.5%, the balance is Mg.

[0069] The preparation method, the specific steps are as follows:

[0070] (1) Melting

[0071] Weigh the raw materials according to the composition ratio of the AM50 magnesium alloy, mix the raw materials and place them in a resistance furnace for melting to obtain the AM50 magnesium alloy melt; N 2 and SF 6 The mixed gas is used as the shielding gas, wherein, in the mixed gas, SF 6 The mass concentration is 0.3%, and the nitrogen mass concentration is SF 6 100 times;

[0072] (2) Preheating

[0073] Preheating the tube blank mold with a cavity in the shape of a tube blank to obtain a preheated tube blank mold; wherein, the preheating temperature is 150°C, and the preheating time is 1h;

[0074] The sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com