Method for preparing high-density biomass fuel for roasting tobacco by tobacco stalks

A biomass fuel, high-density technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of inability to meet the requirements of baking, low density of biomass fuel, hidden dangers of diseases and insect pests, etc., and reduce storage costs and transportation costs. , the effect of improving transportation capacity and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

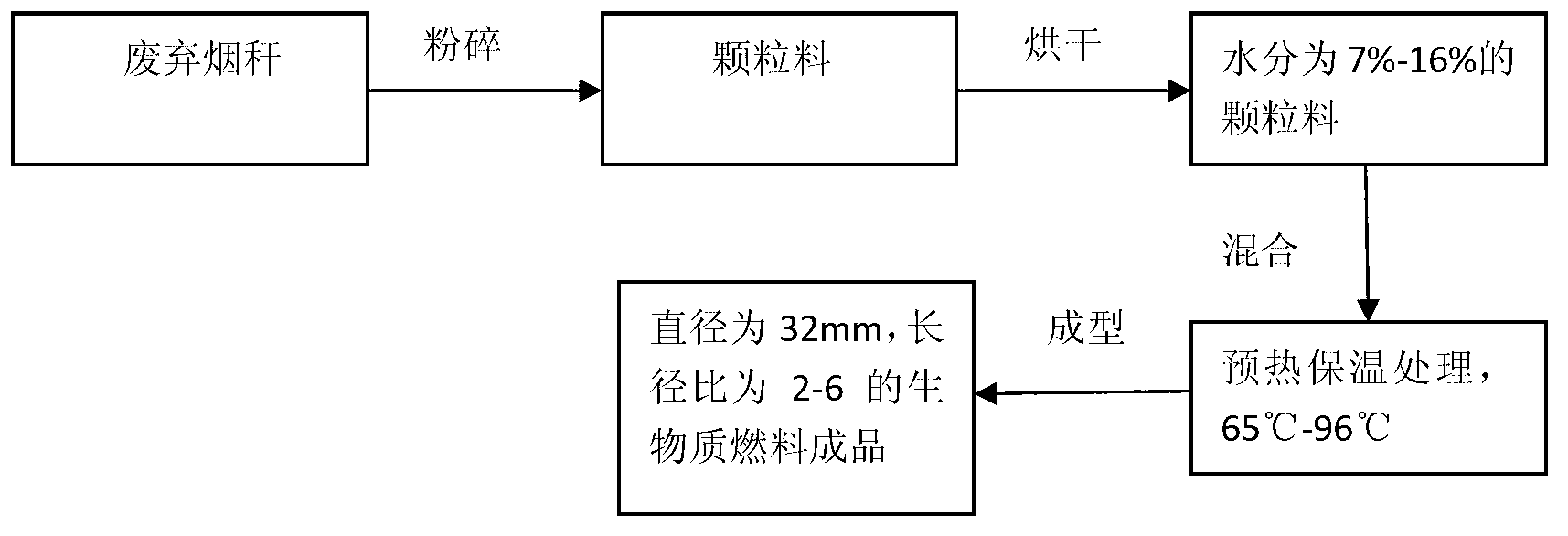

[0017] A method for making tobacco stalks into high-density biomass fuel specially used for tobacco curing—the density is 1.2-1.4g / cm 3

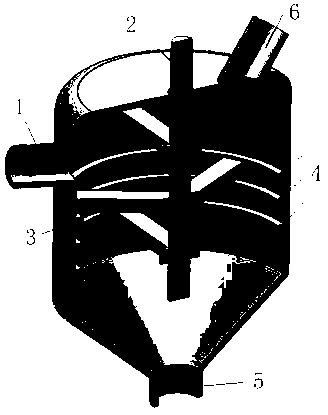

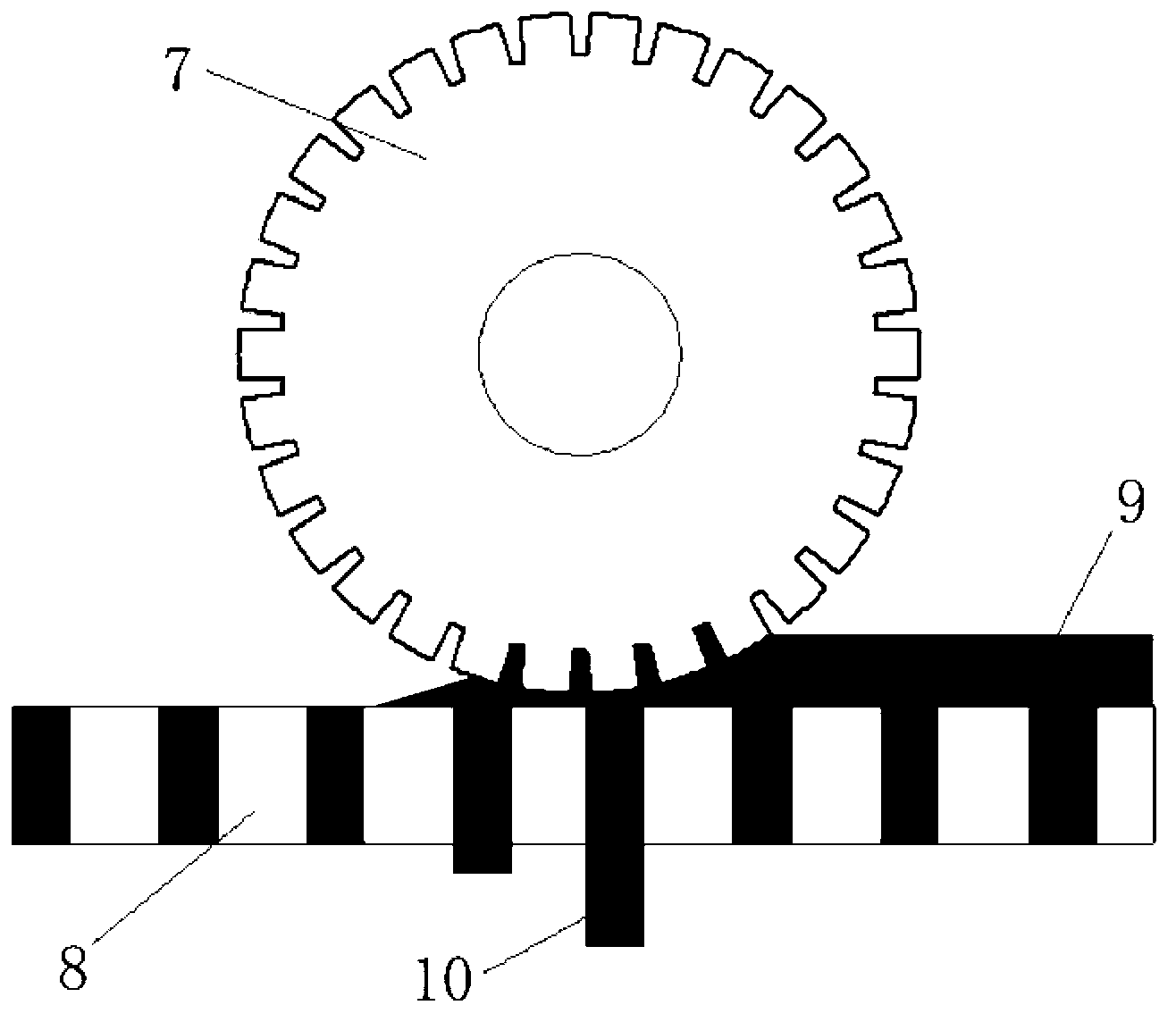

[0018] The method of making tobacco stalks into high-density biomass fuel for tobacco curing is to crush waste tobacco stalks, tobacco stems and waste tobacco leaves into 1-2cm sized pellets; the pellets are dried in a hot air drying furnace, and the moisture requirement is 7%-16%; the dried pellets are heated in a stirring heater and then pressed into shape by high-pressure mechanical equipment. The obtained finished product is a solid cylinder with a diameter of d=32mm and a density of 1.4g / cm 3 , aspect ratio l:d=2-6.

Embodiment 2

[0020] A method for making tobacco stalks into high-density biomass fuel for tobacco curing—the density is 1.3-1.4g / cm 3

[0021] The method of making tobacco stalks into high-density biomass fuel for tobacco curing is to crush waste tobacco stalks, tobacco stems and waste tobacco leaves into 4-6cm sized pellets; the pellets are dried in a hot air drying furnace, and the moisture requirement is 7%-16%; the dried granules are pressed and molded by high-pressure mechanical equipment under high temperature conditions, and the finished product is a solid cylinder with a diameter of d=32mm and a density of 1.3-1.4g / cm 3 , aspect ratio l:d=2-6.

Embodiment 3

[0023] A method for making tobacco stalks into high-density biomass fuel for tobacco curing—the density is 1.2-1.3g / cm 3

[0024] The method of making tobacco stalks into high-density biomass fuel for tobacco curing is to crush waste tobacco stalks, tobacco stems and waste tobacco leaves into 8-10cm granules; the granules are dried in a hot air drying furnace, and the moisture requirement is 7%-16%; the dried granules are pressed and molded by high-pressure mechanical equipment under high temperature conditions, and the finished product is a solid cylinder with a diameter of d=32mm and a density of 1.2-1.3g / cm 3 , aspect ratio l:d=2-6.

[0025] Pellets of different particle sizes are used to produce biomass fuels with different density ranges. These three biomass fuels are used in three different stages of the tobacco curing process: 1.2-1.3g / cm 3 Biomass fuel in density range for yellowing period; 1.3-1.4g / cm 3 Density range and 1.4g / cm 3 Biomass fuel in density range for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com