Intelligent fireproof glass gumming line body machine

A fire-resistant glass and glue coating technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of unsmooth glue line, time-consuming and laborious, complicated steps, etc., so as to avoid glass glue discontinuity, Reduce repeatability and optimize process results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

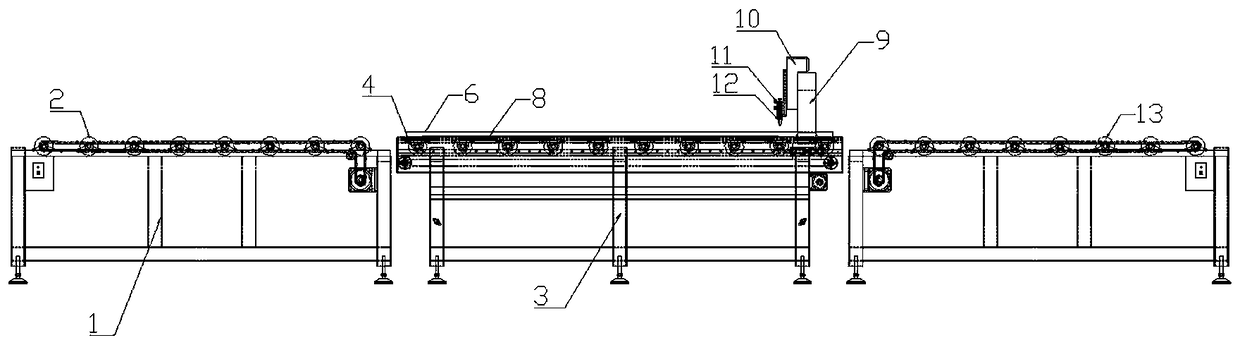

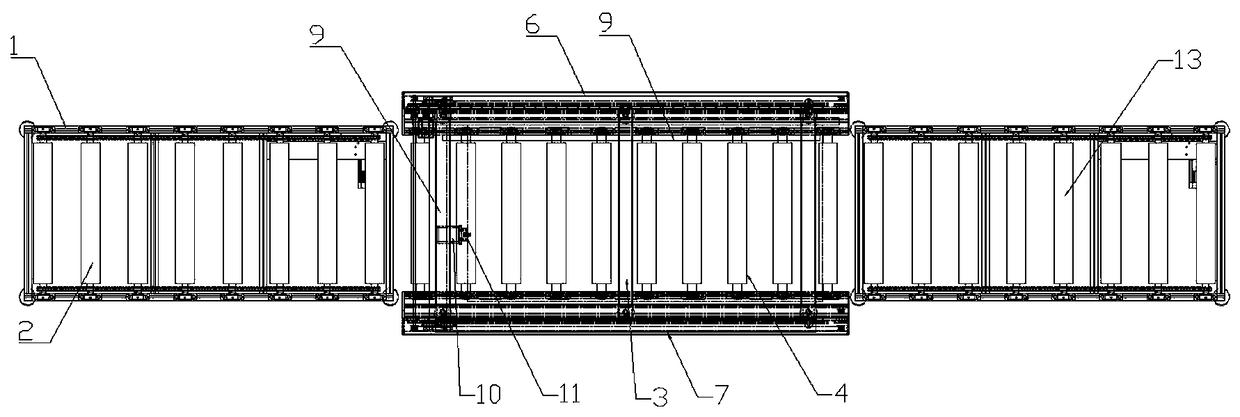

[0032] refer to figure 1 , figure 2 , an intelligent fireproof glass gluing line body machine, including sequentially connected feeding unit, gluing unit and unloading unit,

[0033] The feeding unit includes a first bracket 1, on which a set of rotatable first rolling shafts 2 are arranged;

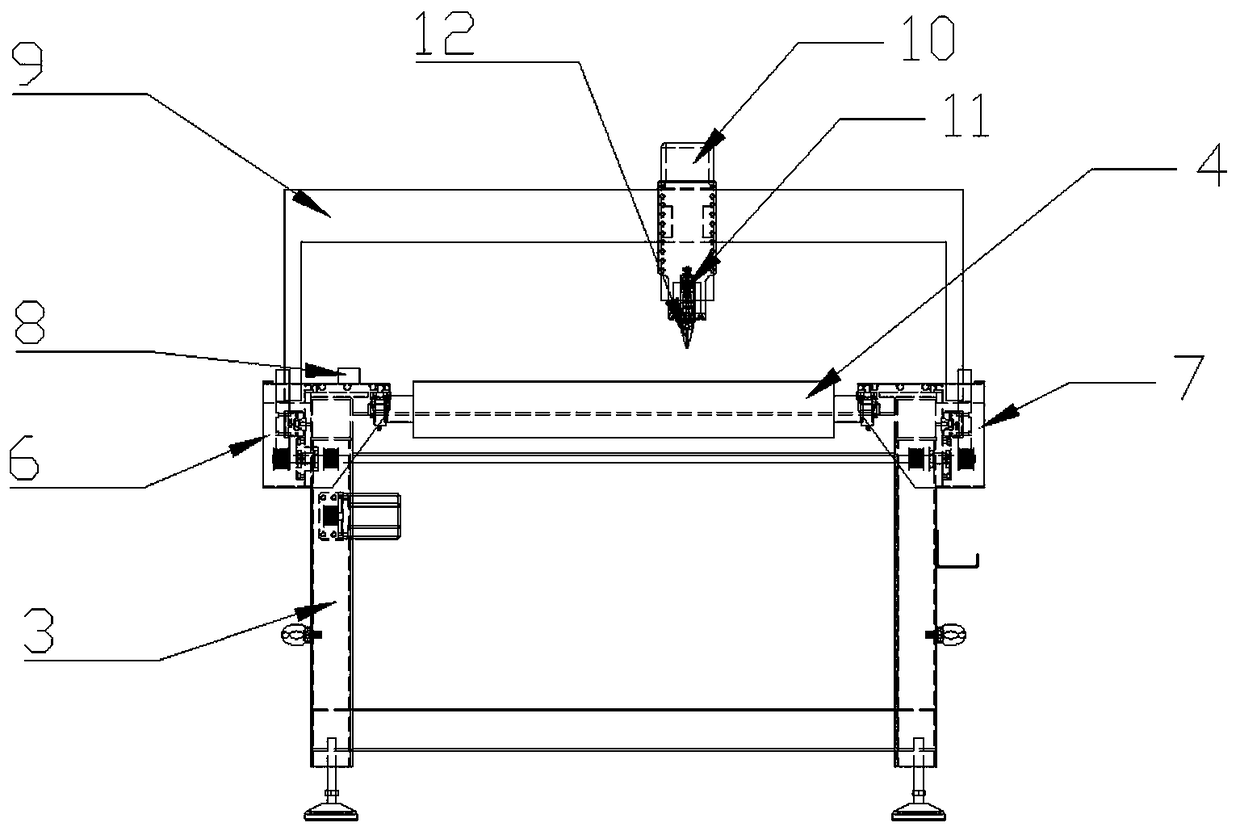

[0034] The gluing unit includes a second bracket 3, on which a group of rotatable second rolling shafts 4 are arranged, and the sides of the second bracket 3 away from the loading unit and the unloading unit are respectively provided with parallel first slide rails 6 and the second slide rail 7, the second rolling shaft 4 is perpendicular to the first slide rail 6, a retractable positioning plate 8 is arranged between the first slide rail 6 and the second slide rail 7, the first slide rail 6 and the second slide rail 7 The top of the two slide rails 7 spans a slidable support rod 9, and the support rod 9 is provided with a sliding slider 10, the slider 10 is fixedly connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com