Plastic crushing device

The technology of a crushing device and a material guiding device is applied in the field of plastic processing, which can solve the problems of material impact rebound and blockage of the feeding port, and achieve the effect of overcoming the blockage of the feeding port, preventing the damage of the device and reducing the work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

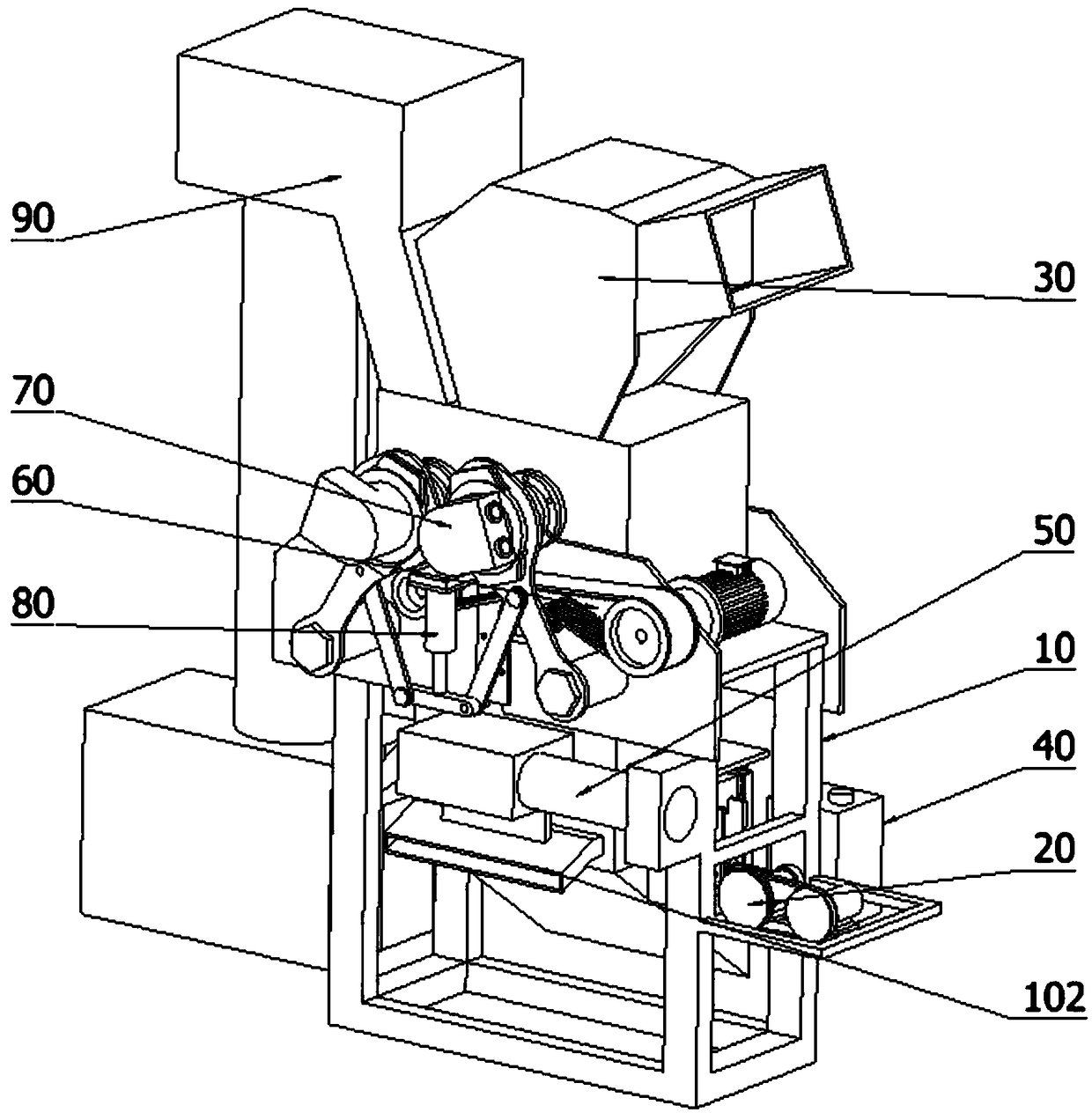

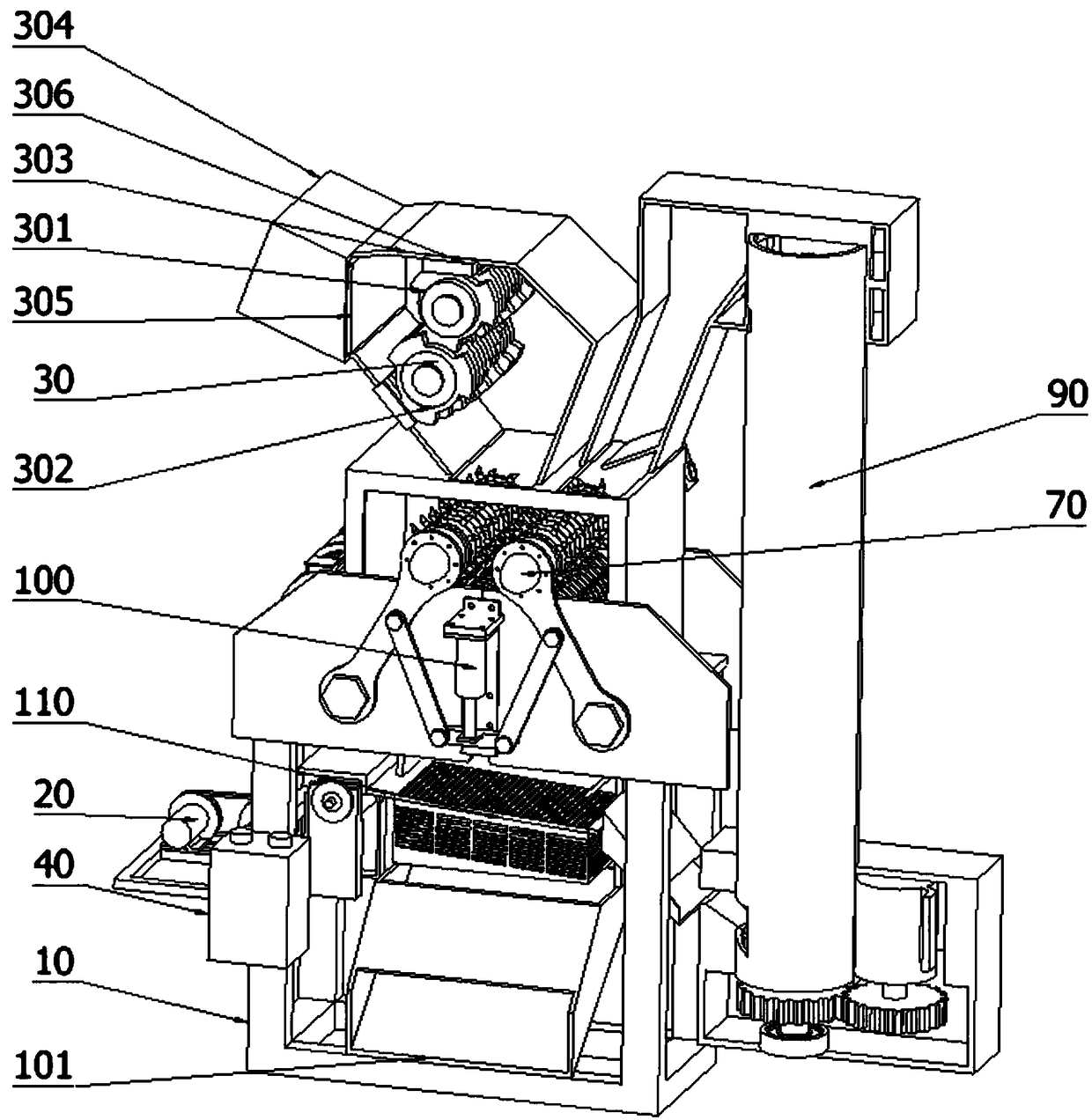

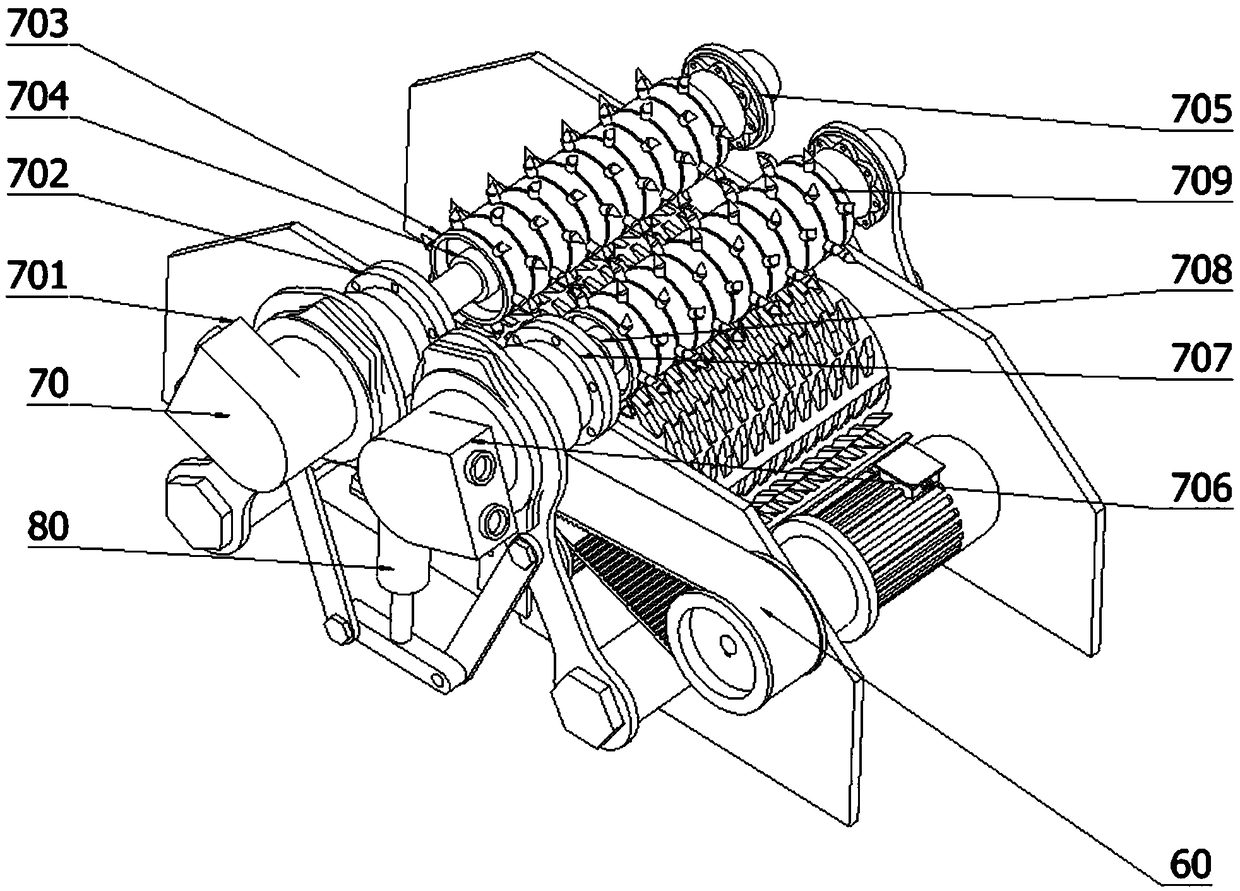

[0078] Such as figure 1 , 2 As shown, this embodiment discloses a crushing device for plastics, including a bracket 10 which is arranged in a rectangular shape as a whole, a rectangular hollow plate is arranged in the middle of the left side of the bracket 10, and a screening device 20 is installed for crushing in the screening box 110. The plastics are quickly screened to prevent excessive broken plastics from forming retention above and inside the screening box 110, causing blockage, reducing work efficiency, and causing damage to the device. A crushing device 60 is installed on the upper surface of the bracket 10, and the crushing device 60 is above the bracket 10. Inside the square shell, a coiling device 70 is installed above the crushing device 60 for the involvement of plastics, and a material guide device 30 is installed above the coiling device 70, and the material guide device 30 is installed on the bracket 10 through the material guide shell 303 The upper surface ...

Embodiment 2

[0082] This embodiment is implemented on the basis of Embodiment 1, including such figure 2 , 8 , shown in 9 and 10, a screening device 20 is installed on the left side of the screening box 110, and the rotating block 206 of the screening device 20 is connected to the lower surface of the left rectangular plate of the screening box 110, and the rectangular hollow block inside the rotating block 206 is provided with Coupling shaft 207 links to each other with the support plate above the left rectangular hollow plate of support 10, and coupling shaft 207 passes the circular through hole of support left side support plate, is provided with eccentric connecting rod 204 in the middle of the vertical rectangular plate of rotating block 206, eccentric The connecting rod 204 is a large circle on the left and a small circle on the right. The right circle of the eccentric connecting rod 204 is connected to the vertical rectangular plate of the rotating block 206 through a circular colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com