Air bag type tire burst safety system

A safety system and airbag-type technology, applied in tire parts, transportation and packaging, vehicle parts, etc., can solve problems such as improper operation of brakes, high cost, and heavy weight, so as to avoid friction, heat, damage, and accidents , to avoid the effect of damage at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

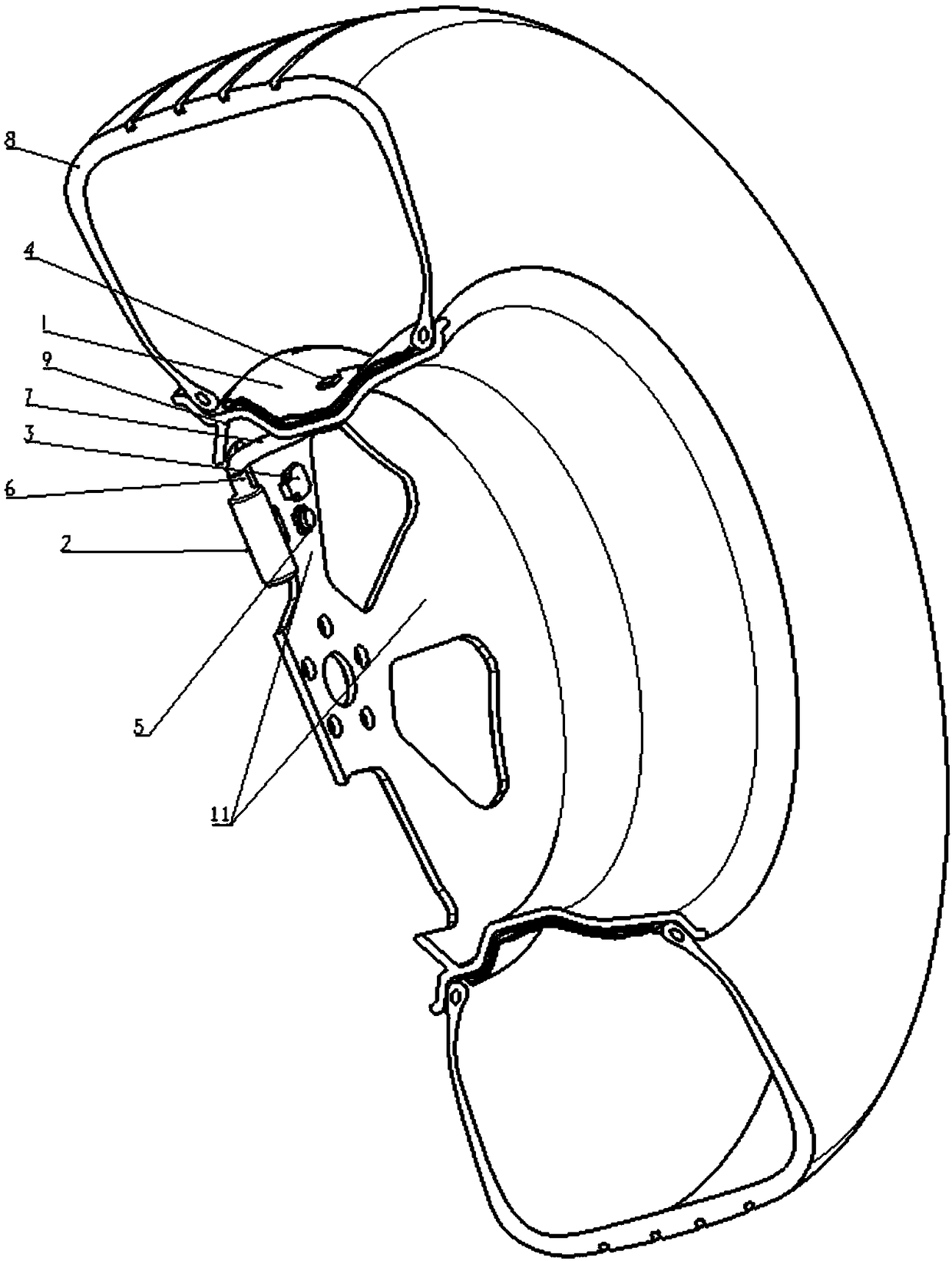

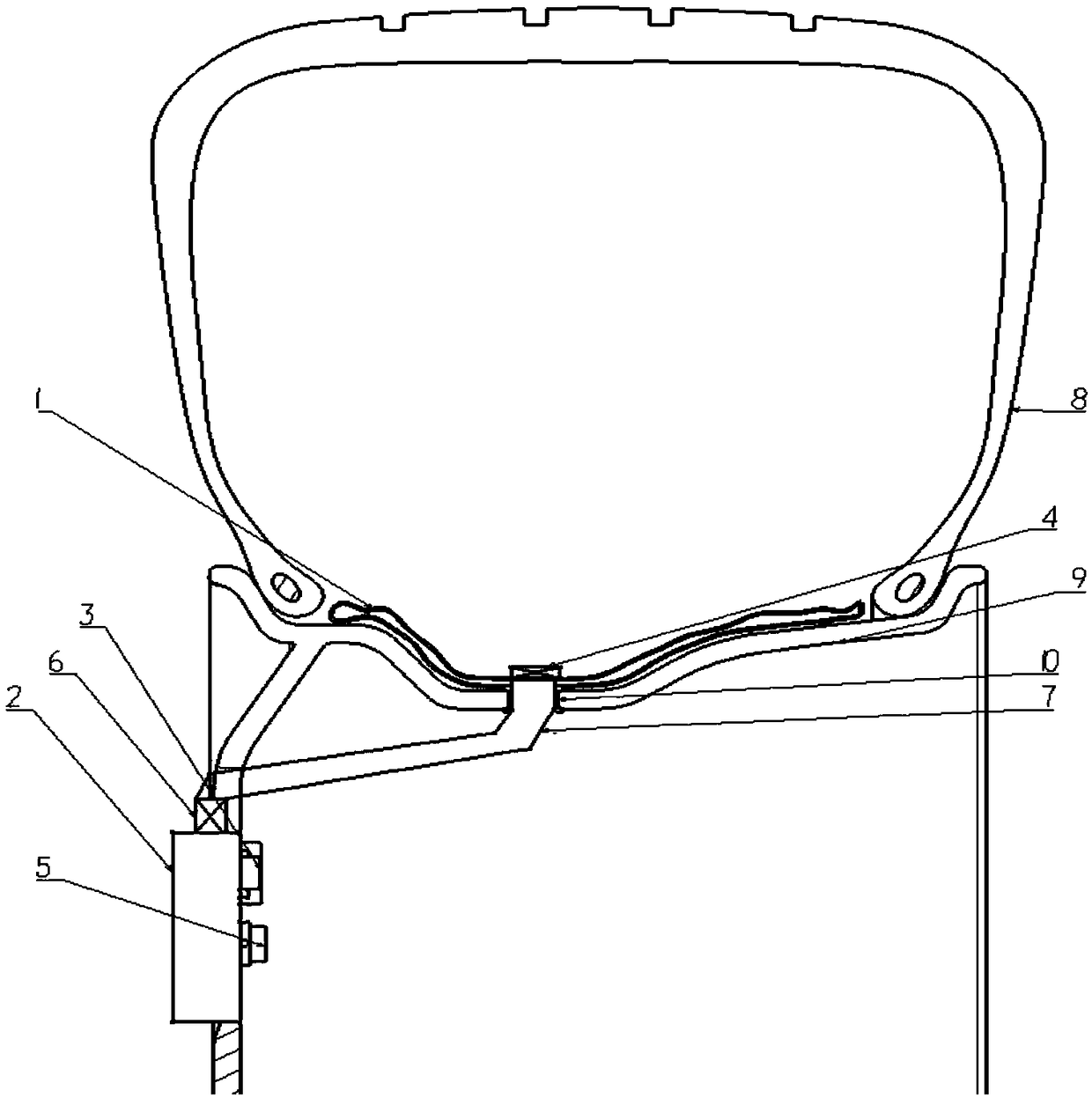

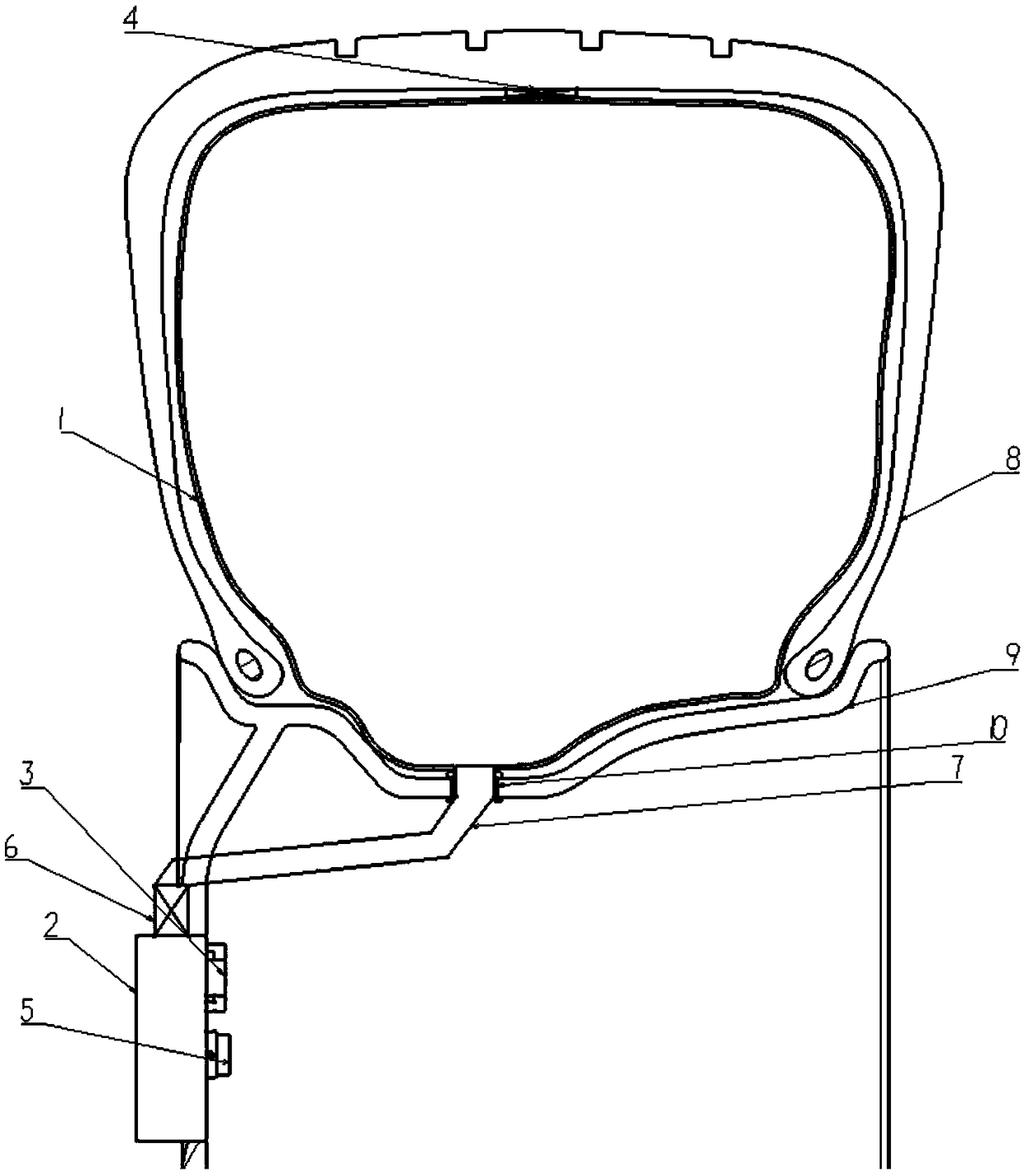

[0020] as attached Figure 1-3 Shown, a kind of airbag type puncture safety system comprises wheel and the tire 8 that is installed on the wheel, and described wheel is by rim 9 and a plurality of spokes 11, also comprises explosion-proof air bag 1, high-pressure gas cylinder 2, gas cylinder valve 6 , an air duct 7, a controller 3 and a sensor for judging whether the tire is blown out; the explosion-proof airbag 1 is hollow and annular, fixedly mounted on the outer circumference of the wheel hub 9 in a folded state, and positioned inside the tire 8; The gas cylinder valve 6 is installed at the outlet of the high-pressure gas cylinder 2 to seal the high-pressure gas; the air guide tube 7 communicates with the high-pressure gas cylinder 2 and the flat tire air bag 1; Holes; the high-pressure gas cylinder 2 is connected with the inflation hole through the air guide tube 7; the sensor includes an air pressure sensor 4 and an acceleration sensor 5; the air pressure sensor 4 is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com