Pressing machine for carton packaging

A technology of a pressing machine and a pressing mechanism, applied in packaging and other directions, can solve problems such as unfavorable production and development of enterprises, increase labor intensity of operators, affect product packaging efficiency, etc., achieve simple and ingenious structure, reduce labor intensity, and ensure packaging. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

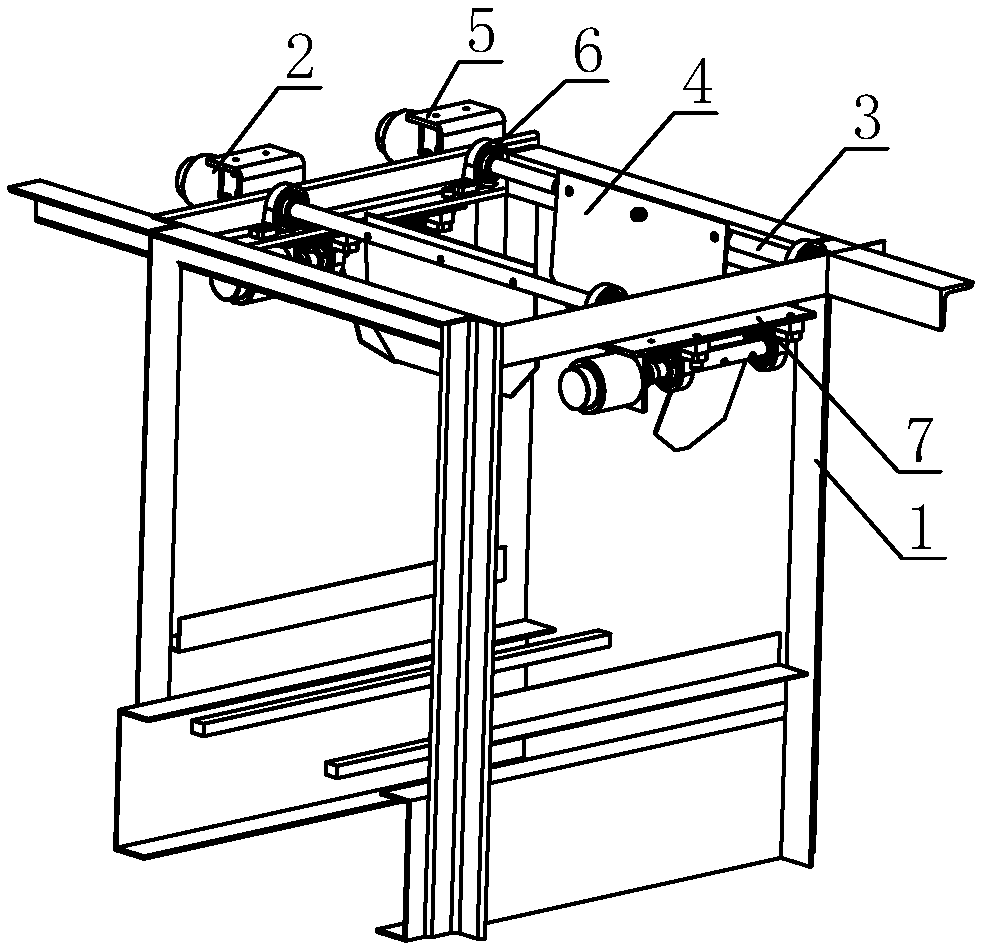

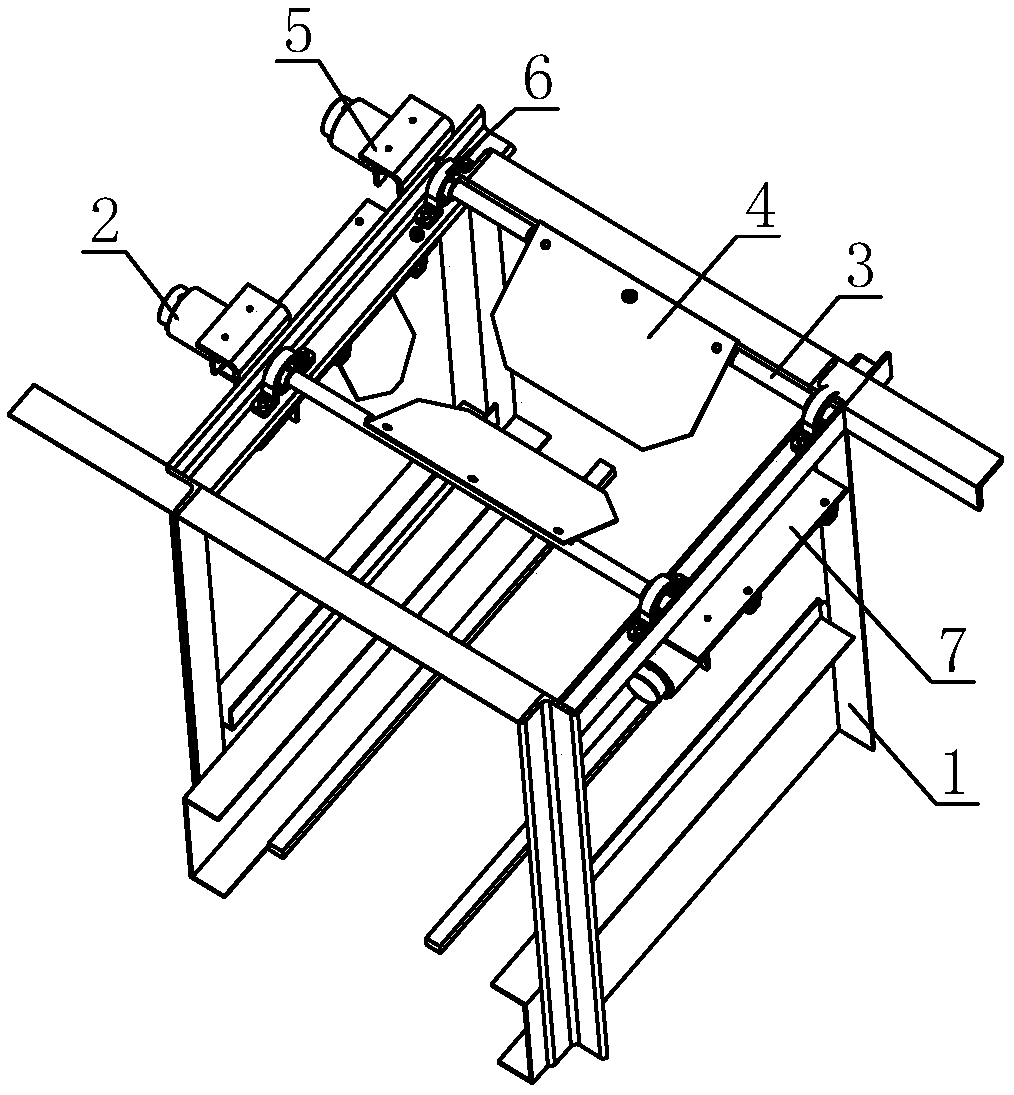

[0025] Example: such as Figure 1 to Figure 6 As shown, the compacting machine used for carton packaging includes a frame 1 fixedly installed on the ground or other planes. The frame 1 is equipped with a compacting mechanism in four directions, that is, it matches the four-sided carton cover on the carton. , to ensure the operation of each carton cover, in order to ensure that the compactor can be applied to cartons of different sizes, a moving mechanism that can move the compacting mechanism can also be set between the frame 1 and the compacting mechanism, The moving mechanism can be a moving plate with a simple structure, plus a shifting drive motor that drives the moving plate to move.

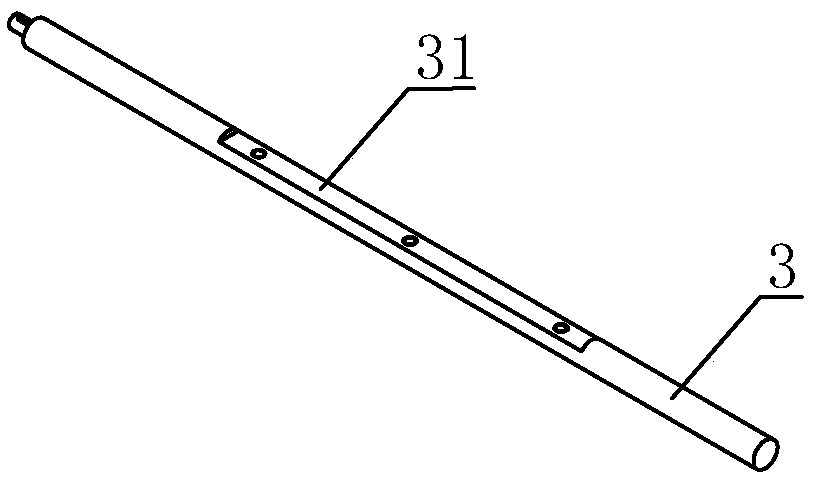

[0026] The pressing mechanism comprises a pressing plate 4, an overturning roller 3 and a driving mechanism 2. The pressing plate 4 is fixedly installed on the overturning roller 3 through locking mechanisms such as locking bolts, and the overturning roller 3 is connected to the output end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com