Feed automatic truck loading crane

A crane and automatic technology, applied in the direction of lifting equipment braking device, hoisting device, transportation and packaging, etc., can solve the problems of waste of manpower and physical strength, inconvenient use, low degree of intelligence, etc., and achieve long service life and simple structure. , the effect of a high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

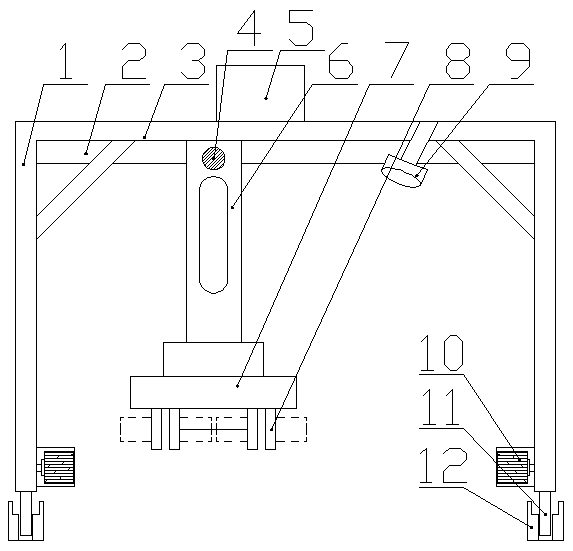

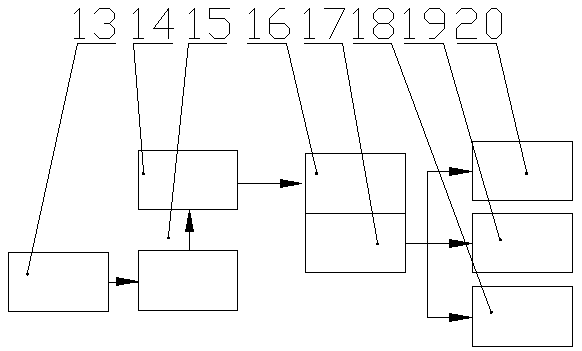

[0015] Such as figure 1 , figure 2 As shown, a feed automatic loading crane, it includes a frame body 1 and a control box 5, the upper end of the frame body 1 is equipped with a beam 3, the lower side of the beam 3 is provided with a moving track 2, the The moving track 2 is provided with a moving boom 6, the upper end of the moving boom 6 is connected to the output end of the first motor 4, and the lower end of the moving boom 6 is provided with a hanger 7, so The hanger 7 includes two jaws 8 arranged in parallel, the beam 3 is provided with a camera 9, the bottom of the frame body 1 is provided with a moving wheel 11, and the moving wheel 11 is connected to a second The output end of the second motor 10, the bottom of the moving wheel 11 is correspondingly provided with a walking track 12, the control box 5 is arranged on the upper end of the beam 3, and the control box 5 includes a central control layer 16 and a special control layer 17 , the dedicated control layer 17 i...

Embodiment 2

[0018] Such as figure 1 , figure 2 As shown, a feed automatic loading crane, it includes a frame body 1 and a control box 5, the upper end of the frame body 1 is equipped with a beam 3, the lower side of the beam 3 is provided with a moving track 2, the The moving track 2 is provided with a moving boom 6, the upper end of the moving boom 6 is connected to the output end of the first motor 4, and the lower end of the moving boom 6 is provided with a hanger 7, so The hanger 7 includes two jaws 8 arranged in parallel, the beam 3 is provided with a camera 9, the bottom of the frame body 1 is provided with a moving wheel 11, and the moving wheel 11 is connected to a second The output end of the second motor 10, the bottom of the moving wheel 11 is correspondingly provided with a walking track 12, the control box 5 is arranged on the upper end of the beam 3, and the control box 5 includes a central control layer 16 and a special control layer 17 , the dedicated control layer 17 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com