Starch double-crosslinking network hydrogel and preparation method thereof

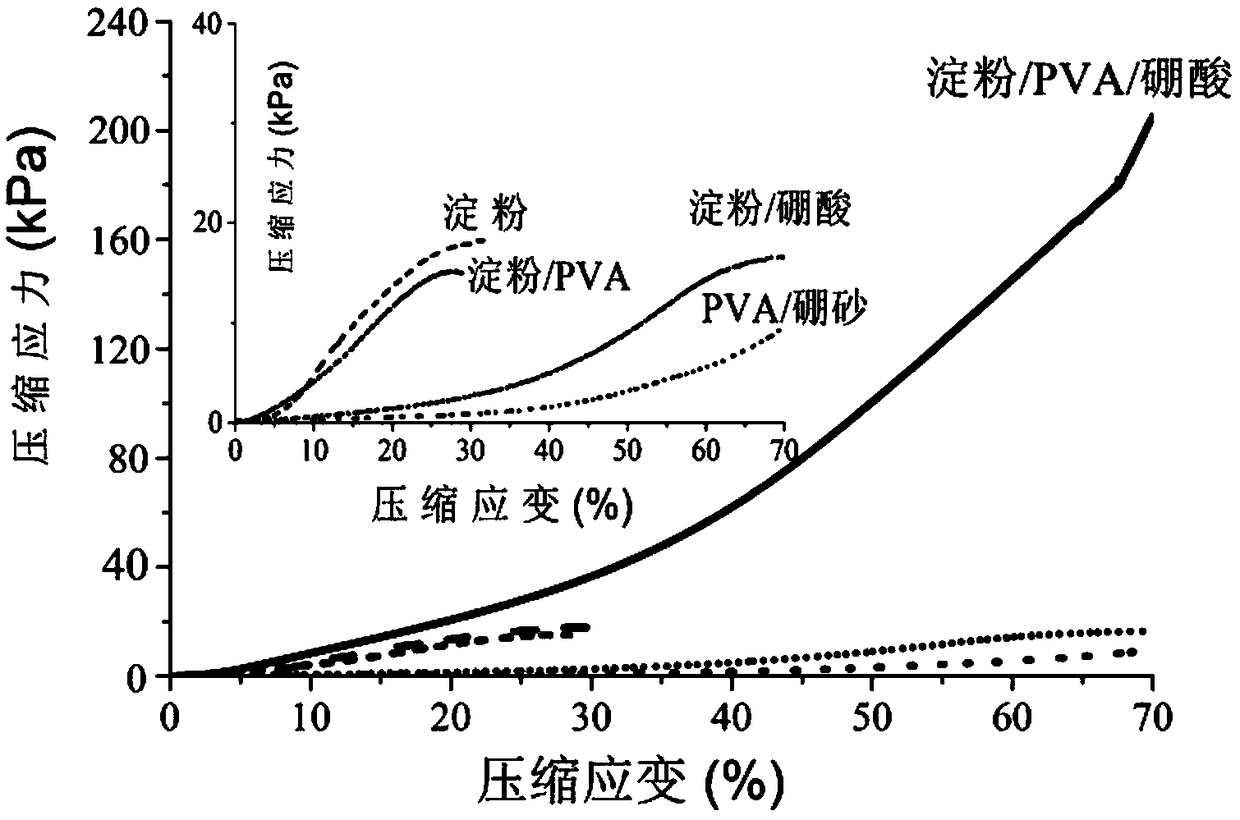

A double-crosslinking and hydrogel technology, applied in the field of natural biomacromolecule gel materials, achieves the effects of simple operation, compressive strength and compressive strain recovery, and strong mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

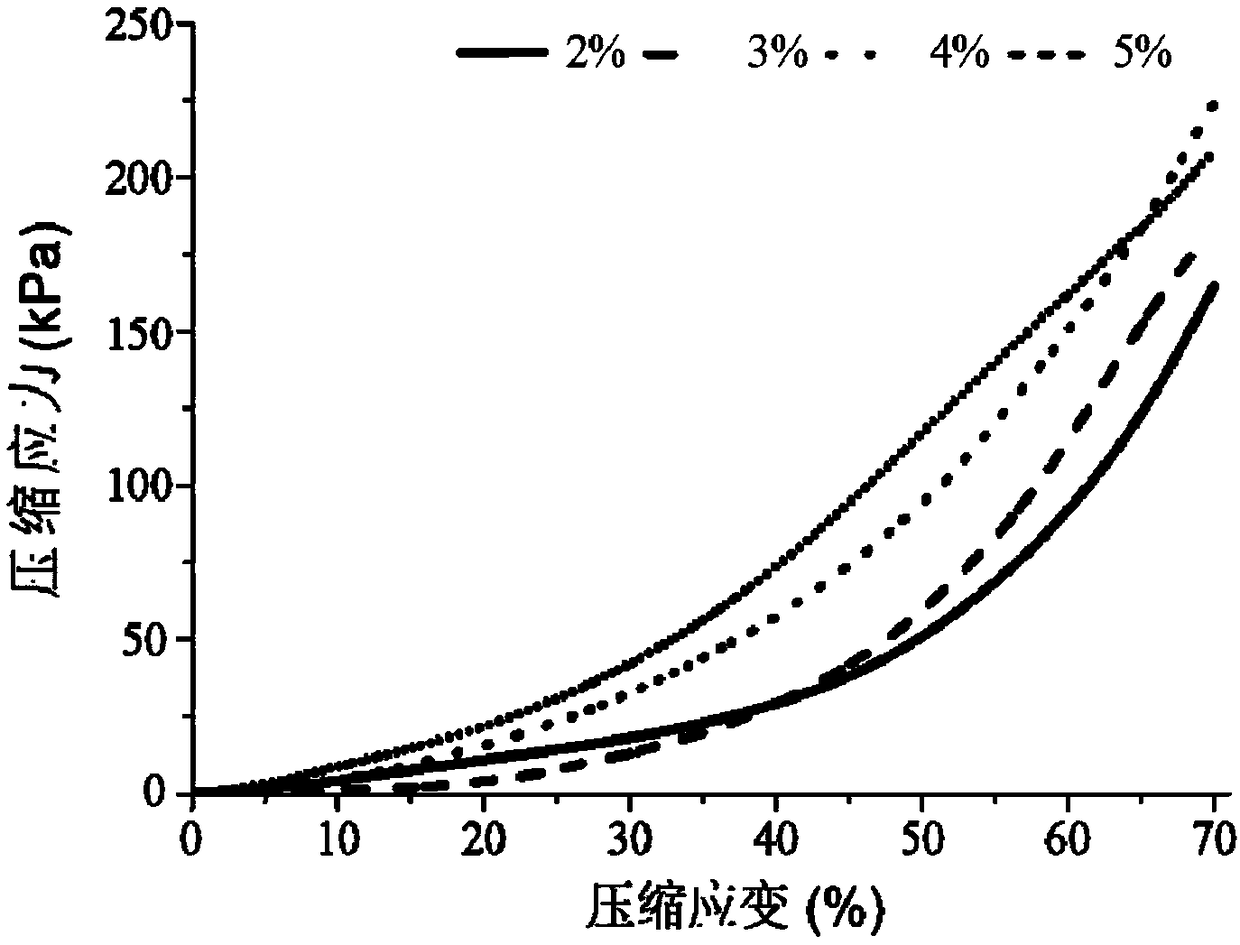

[0048] Prepare starch / PVA / borax double cross-linked network hydrogel according to the following steps:

[0049] (1) Preparation of starch / PVA mixed sol: configure the concentration of PVA to be 3wt%, take 3g of PVA, dissolve it in 87mL deionized water, stir in a 95°C constant temperature water bath, 300r / min for 0.5h, the PVA is fully hydrated and swollen; To room temperature, add 10 g of cornstarch to the cooled PVA solution (the concentration of cornstarch is 10wt%), mix and stir at 300r / min, stir in a 95°C constant temperature water bath for 1.0h, and obtain a uniform starch / PVA mixed sol ;

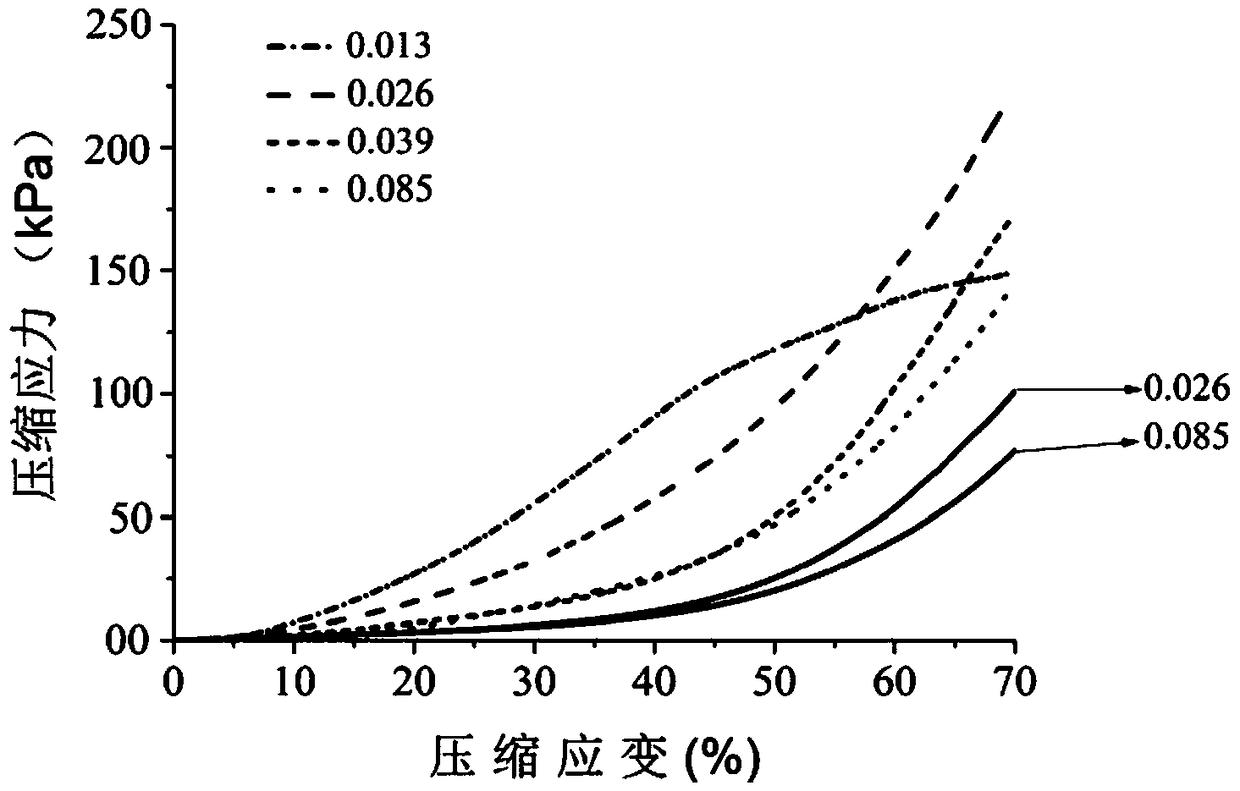

[0050] (2) Preparation of starch / PVA / borax mixed sol: Take a certain amount of borax and add it to the starch / PVA mixed sol, the final concentration of borax is 0.026mol / L, heat in a constant temperature water bath at 95°C and stir at 250r / min for 1.0h , so that the borax is fully dissolved, the sol is ultrasonicated at 75°C for 3 minutes to remove air bubbles, and the starch / PVA / bora...

Embodiment 2

[0053] (1) Preparation of starch / PVA mixed sol: configure the concentration of PVA to be 4wt%, take 4g of PVA, dissolve it in 86mL of deionized water, stir in a 95°C constant temperature water bath, 300r / min for 0.5h, the PVA is fully hydrated and swollen; To room temperature, add 10 g of cornstarch to the cooled PVA solution (the concentration of cornstarch is 10wt%), mix and stir at 300r / min, stir in a 95°C constant temperature water bath for 1.0h, and obtain a uniform starch / PVA mixed sol ;

[0054] (2) Preparation of starch / PVA / borax mixed sol: Take a certain amount of borax and add it to the starch / PVA mixed sol, the final concentration of borax is 0.026mol / L, heat in a constant temperature water bath at 95°C and stir at 250r / min for 1.0h , so that the borax is fully dissolved, the sol is ultrasonicated at 75°C for 3 minutes to remove air bubbles, and the starch / PVA / borax mixed sol is obtained;

[0055] (3) Preparation of starch / PVA / borax double-crosslinked network hydro...

Embodiment 3

[0057] (1) Preparation of starch / PVA mixed sol: configure the concentration of PVA to be 5wt%, take 5g of PVA, dissolve it in 85mL of deionized water, put it in a constant temperature water bath at 95°C, stir at 100r / min for 2h, the PVA is fully hydrated and swollen; At room temperature, add 10 g of cornstarch to the cooled PVA solution (the concentration of cornstarch is 10wt%), mix and stir at 100 r / min, stir in a 95°C constant temperature water bath for 2.0h, and obtain a uniform starch / PVA mixed sol;

[0058] (2) Preparation of starch / PVA / borax mixed sol: Take a certain amount of borax and add it to the starch / PVA mixed sol, the final concentration of borax is 0.026mol / L, heat in a constant temperature water bath at 95°C and stir at 800r / min for 0.5h , so that the borax is fully dissolved, the sol is ultrasonicated at 75°C for 3 minutes to remove air bubbles, and the starch / PVA / borax mixed sol is obtained;

[0059] (3) Preparation of starch / PVA / borax double-crosslinked net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com